Broad sense crankcase oil tray for motorboat engine

A technology for engines and motorboats, which is applied in the directions of engine lubrication, engine components, machines/engines, etc. It can solve problems such as piston ring jamming, power drop, and engine fuel consumption increase, so as to ensure reliability and improve corrosion resistance , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

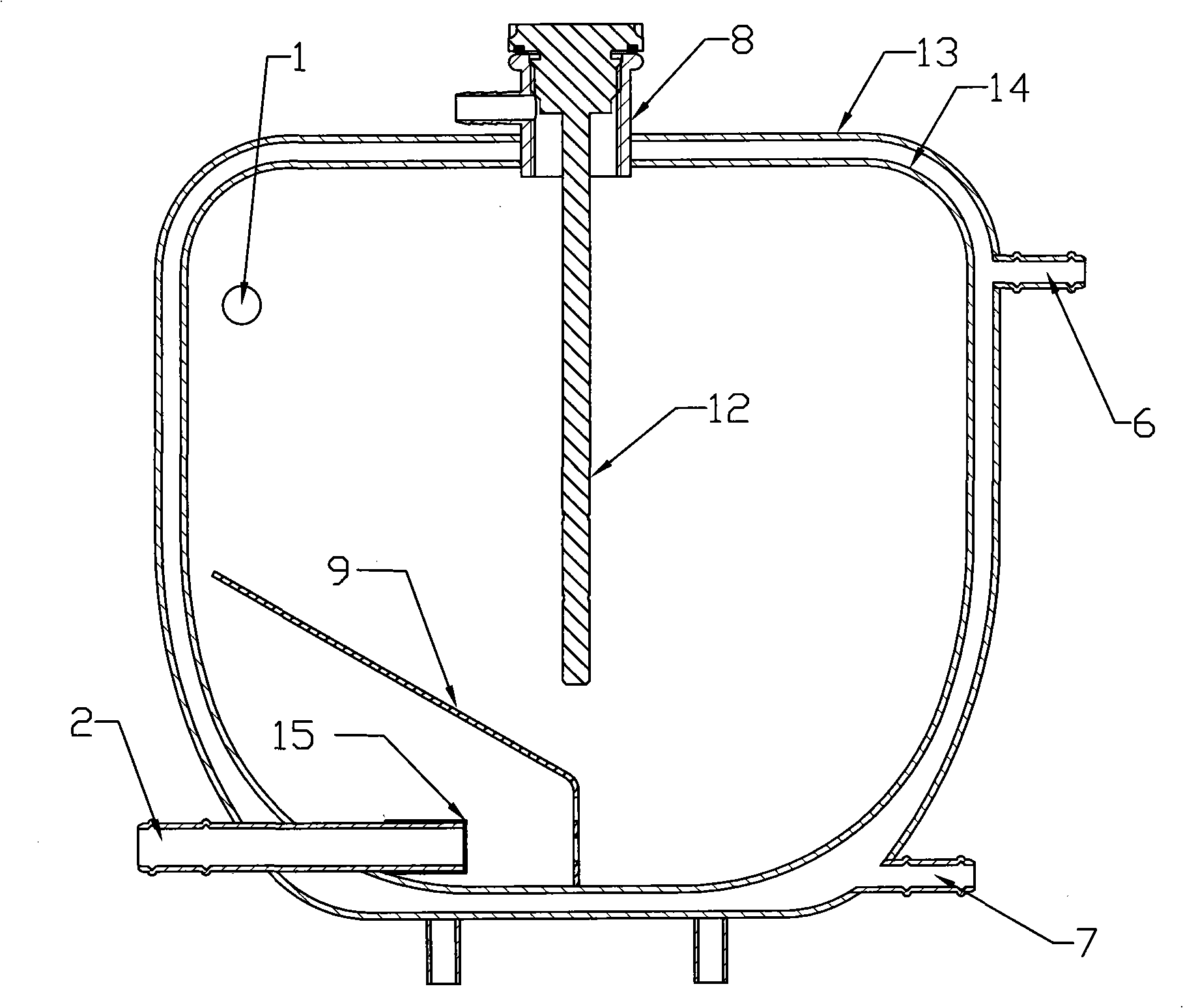

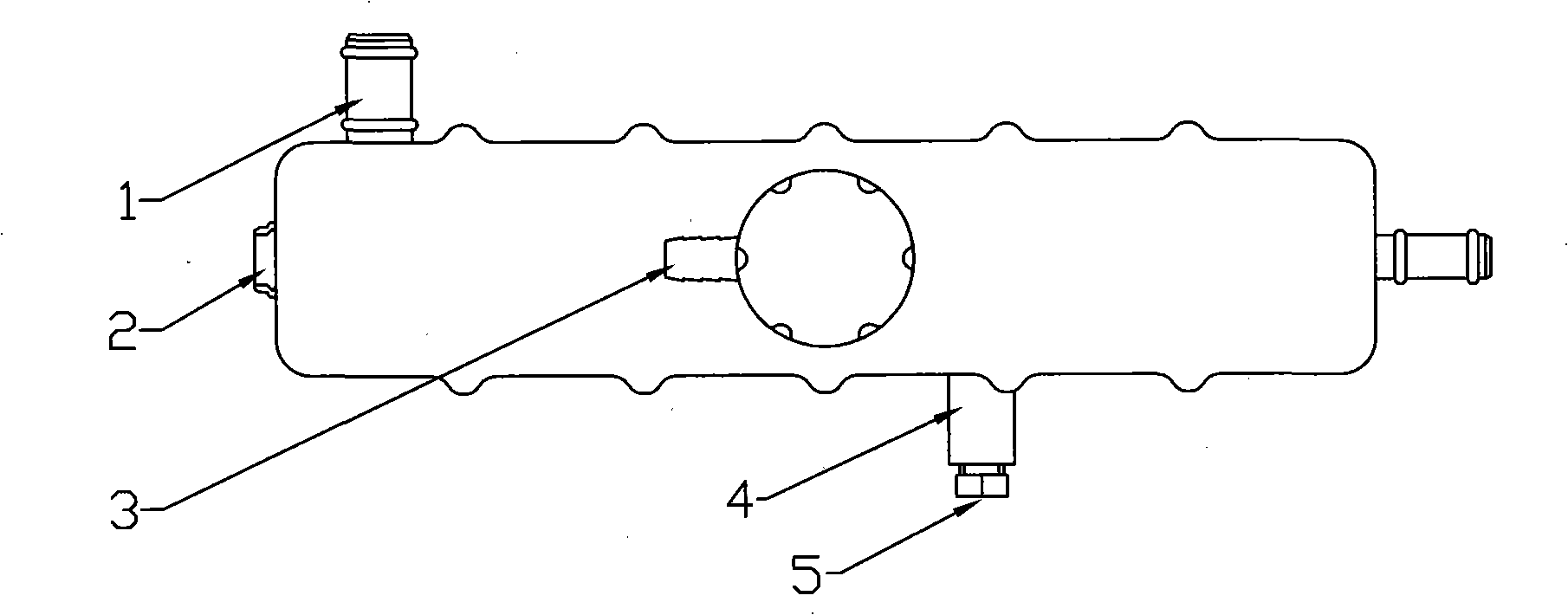

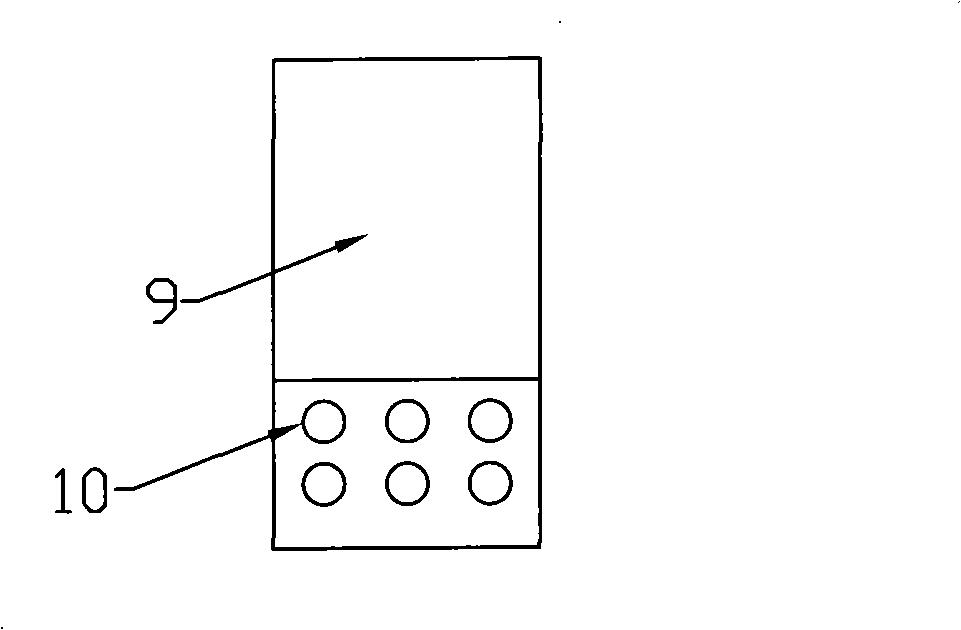

[0024] The generalized oil pan of the motorboat engine is like figure 1 As shown, there are an inner shell 14 and an outer shell 13, an oil inlet pipe joint 1 and an oil outlet pipe joint 2, an inlet pipe joint 7 and an outlet pipe joint 6, an oil drain plug seat 4 and an oil drain plug 5, and refuel Port seat 8 and fuel filler cap 11, as well as oil dipstick 12, oil baffle 9, see figure 1 , figure 2 with image 3 . Engine oil is stored in the inner shell 14, and cooling water flows in the jacket between the inner shell 14 and the outer shell 13. The oil outlet pipe joint 2 is arranged at the bottom of the inner shell 14, and a filter screen 15 is installed at the end of the inner shell 14 that is submerged in the lubricating oil; the oil inlet pipe joint 1 is arranged on the inner shell 14 Ensure that the oil inlet pipe connected to the oil inlet pipe joint 1 is always above the oil level. The water inlet pipe joint 7 is arranged at the bottom of the outer shell 13 and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com