Steam turbine lubricating oil composition with low greasy filth

A technology of lubricating oil composition and steam turbine, which is applied in the field of lubricating oil composition and low-sludge steam turbine lubricating oil composition. It can solve the problems of poor high temperature resistance and oxidation resistance and rapid sludge formation, and achieve excellent high temperature resistance and oxidation resistance. , Excellent anti-rust effect

Active Publication Date: 2016-07-06

PETROCHINA CO LTD

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0018] The disadvantages of this patent are that the sludge formation tends to be faster, the high temperature resistance and oxidation resistance are slightly poor, or it is difficult to meet the above two points at the same time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

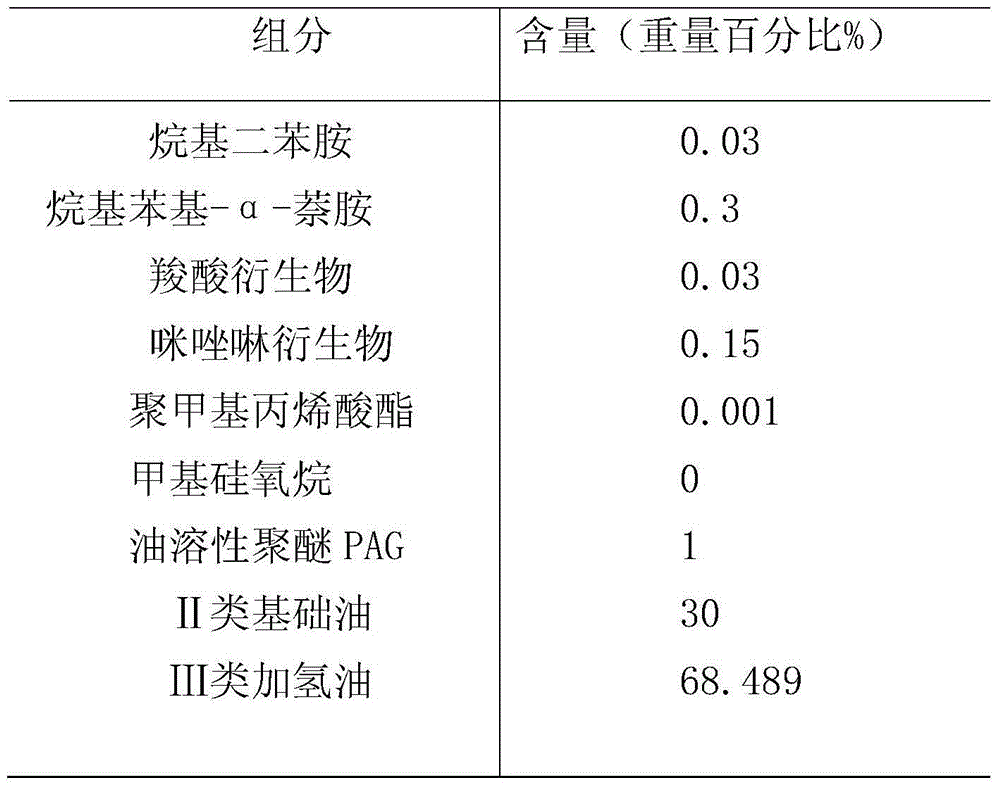

Embodiment 1

[0067]

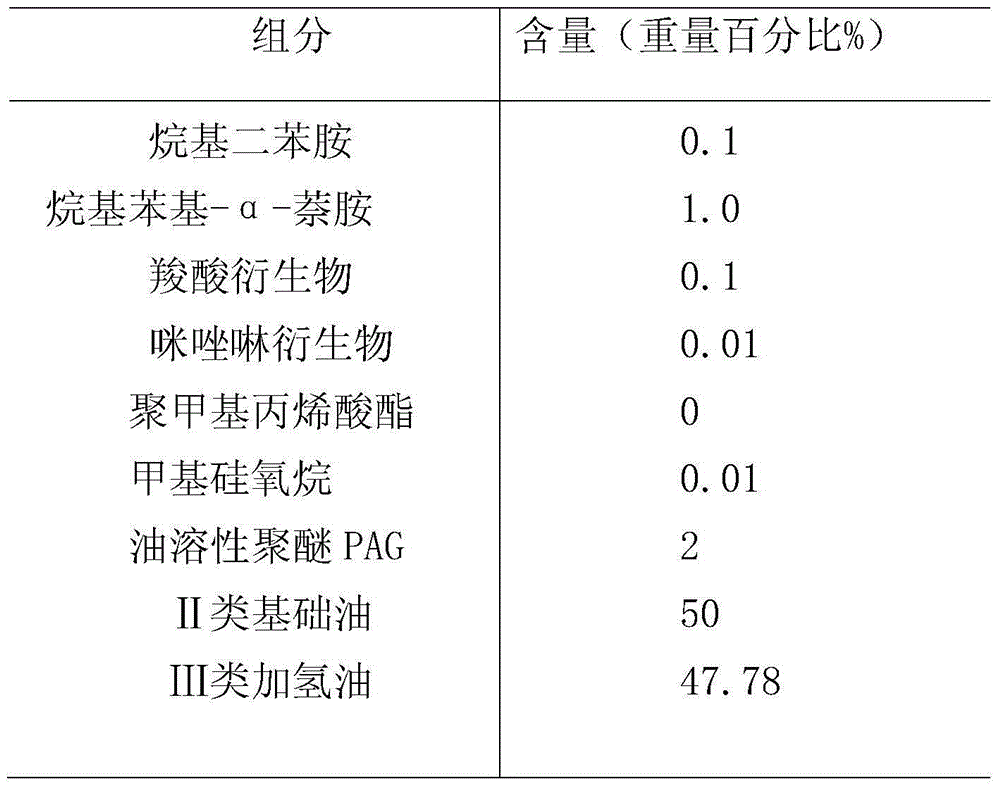

Embodiment 2

[0069]

Embodiment 3

[0071]

[0072]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of steam turbine lubrication, and is a low-sludge steam turbine lubricating oil composition. 0.03% to 0.2% antirust agent compounded with derivatives, 0.001% to 0.1% antifoaming agent, 1% to 20% polyether, and base oil as the balance. The advantages of the present invention: excellent high temperature resistance and oxidation resistance, in the Dry-TOST test at 120°C, the oxidation life of the remaining rotary oxygen bomb rate of 25% is at least 500 hours, the rotary oxygen bomb is more than 900 minutes, and the TOST oxidation life is more than 10000 Hours; very little sludge formation tendency, in the Dry-TOST test at 120°C, the sludge formation is less than 60mg / kg when the remaining rotary oxygen bomb rate is 25%, and the sludge formation is less than 200mg after TOST test 1000h; the composition can be very good Meet the lubrication requirements of steam turbines and gas turbines with low oil sludge requirements.

Description

technical field [0001] The invention belongs to the technical field of steam turbine lubrication, and relates to a lubricating oil composition, in particular to a low-sludge steam-turbine lubricating oil composition, which is suitable for use in steam turbines, gas turbines and large gas-steam combined cycle units. thing. Background technique [0002] Because the initial gas temperature of the gas turbine can be as high as 1200℃, the oil temperature is about 50℃~95℃, and the maximum oil temperature at the bearing is about 120℃. The continuous increase in the volume of the fuel tank, that is, the continuous increase in the circulation coefficient of the turbine oil, requires the turbine oil to have a long anti-oxidative life under high temperature conditions. Secondly, the sludge problem is a common problem in the operation of steam turbines. The steam turbine is affected by external factors during operation, such as high temperature, water, air, steam, dust particles, etc....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/10C10N30/12C10N30/18C10N40/12

Inventor 孙大新王辉金琴华杨丽郑延波

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com