Composition for anti-ammonia turbine oil

A technology of steam turbine oil and composition, which is applied in the direction of lubricating composition, petroleum industry, base material, etc. It can solve the problems that cannot be completely removed, cannot meet the lubrication needs, etc., and achieve good air release, excellent oxidation stability, and improve efficiency Effect

Inactive Publication Date: 2010-06-09

PETROCHINA CO LTD

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The anti-ammonia turbine oil currently on the domestic market basically adopts the Class I base oil produced by the solvent refining process. The base oil produced by this process cannot completely remove polar substances such as aromatics, heterocycles, and colloids in the oil, so Under the action of high temperature and water, it is easy to oxidize and deteriorate to form sludge and paint film, so it cannot meet the lubrication needs of new technologies for synthesis gas and ammonia compressors and steam turbines in modern petrochemical, gas production and chemical fertilizer industries.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

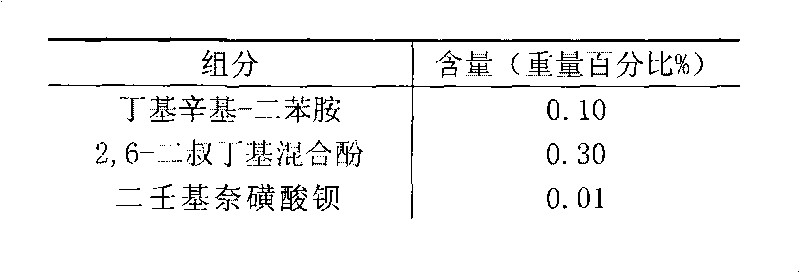

Embodiment 1

[0026]

[0027]

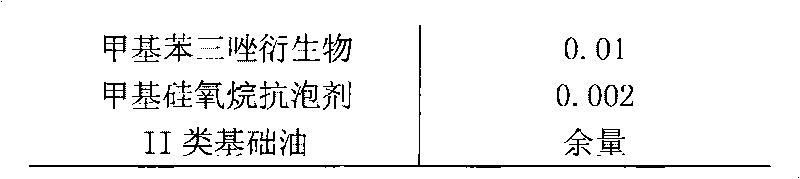

Embodiment 2

[0029]

Embodiment 3

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a composition for anti-ammonia turbine oil. The composition comprises the following components by weight percentage: 1.1-2.0% of screening phenol antioxygen, alkyl diphenylamine antioxygen or formulated mixture antioxygen thereof, 0.01-2.0% of non-acid antirusting agent, 0.01-1% of metal passivator, 0.001-0.01% of anti-foaming agent and the balance of base oil. The base oil is II type hydrogenated base oil, and in the II type hydrogenated base oil, the sulphur content of the II type hydrogenated base oil based on weight is no more than 0.03%, and the saturation is no less than 90%. The antioxygen is formulated by the screening phenol antioxygen and the alkyl diphenylamine antioxygen, and the weight proportion of the antioxygen 1:0.1-10. The invention has the advantages of excellent lubricity, oxidation stability, favorable water separation, air release property and strong anticorrosion property, maintains neutral for ammonia and synthesis gas, has little possibility of sludge generation, reduces the time of machine halt, andreduces operation and maintenance cost.

Description

technical field [0001] The present invention relates to a lubricating oil composition, especially suitable for steam turbine oil composition with ammonia and synthesis gas compressors. Background technique [0002] In modern petrochemical, gas production and chemical fertilizer industries, compressors for synthesis gas and ammonia are often driven by steam turbines, and the compressor and steam turbine often use the same lubricating oil, that is, ammonia-resistant turbine oil. The characteristic of this oil is that it does not react chemically with ammonia. [0003] In recent years, with the extension of equipment maintenance period, higher requirements have been put forward for the performance of oil products. The ideal lubricant for the application of synthesis gas and ammonia gas is: it has excellent oxidation stability and oil-water separation, so as to reduce Oil change cycle and cost; it has better lubricity for air compressors, reduces wear and tear to make the syste...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M101/00C10M127/00C10N40/00

Inventor 徐平郝玉杰

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com