Epoxy ester resin water dispersion and method for manufacturing rust-inhibiting primer using the same as foundation

A technology of epoxy ester resin and anti-rust primer, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problem of decreased hardness and water resistance of epoxy ester resin, poor film-forming property and anti-corrosion performance, The problem of high acid value of epoxy ester resin can achieve the effect of good water resistance, excellent anti-corrosion performance and good self-drying property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

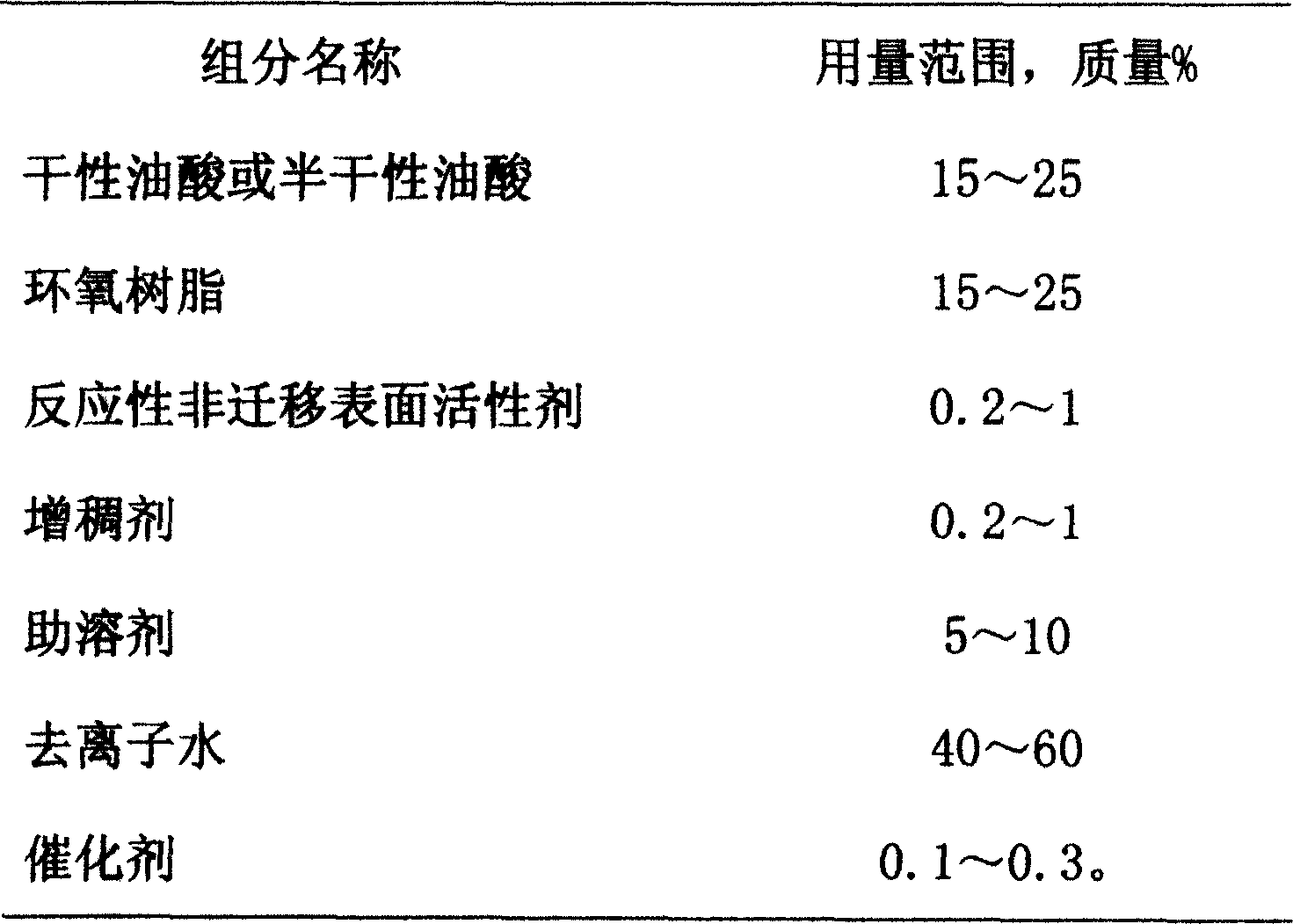

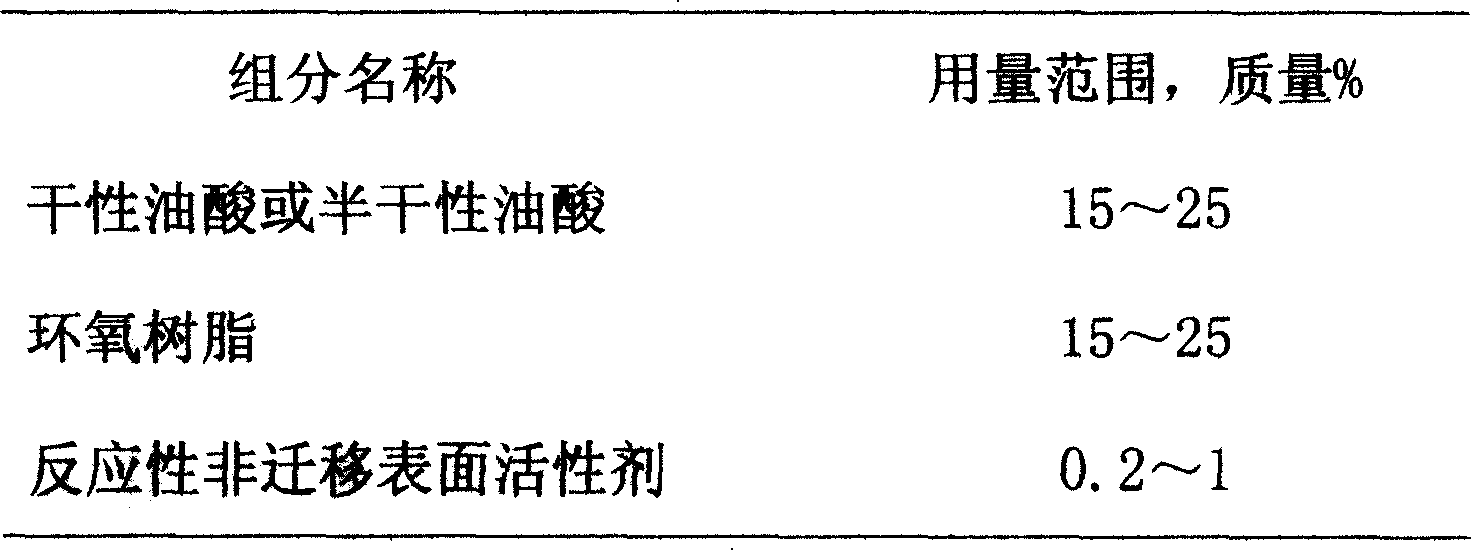

[0027] This example is intended to demonstrate the fabrication of epoxy ester resin emulsions.

[0028] (1) Synthetic epoxy ester resin

[0029] Add 108 g of linoleic acid, 432 g of linoleic acid and 90 g of xylene into the reaction vessel, and stir to raise the temperature. When the temperature is raised to 120°C, add epoxy resin and catalyst, continue to heat up to 240°C, and keep the reaction at this temperature until the acid value is 5mgKOH / g, then cool down to obtain epoxy ester resin. Wherein the grade of epoxy resin used is: E-12; Consumption is 540g. The name of the catalyst is: benzyltriethylammonium chloride; the dosage is 7.2g.

[0030] (2) Epoxy ester resin refers to water-based

[0031]Dissolve 2 g of the associative thickener in 180 g of deionized water in advance to make an aqueous thickener solution for later use. Add the above-mentioned epoxy ester resin, reactive non-migrating surfactant, and co-solvent into an adjustable-speed high-speed stirring tank, ...

Embodiment 2

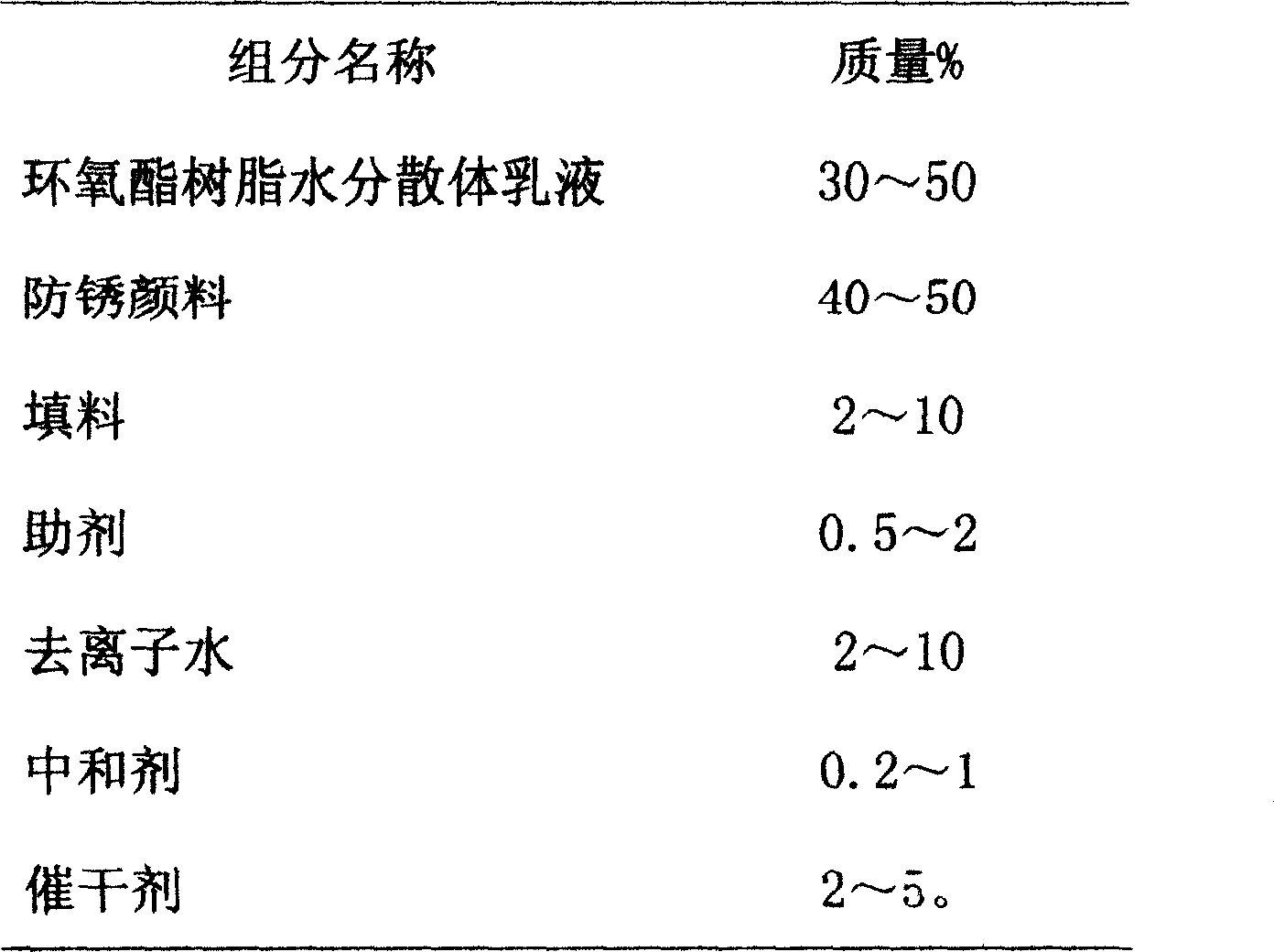

[0033] This example is intended to demonstrate the preparation of an antirust primer with the above-mentioned epoxy ester resin aqueous dispersion emulsion.

[0034] Add 3g of deionized water, 0.5g of defoamer, 0.6g of thickener, and 1g of ammonia water (25%) into a high-speed stirring tank, and stir evenly with an adjustable high-speed disperser. Add 9.8g of iron red paste, 4g of filler paste, 42.8g of zinc phosphate paste and 9g of ZP-10 paste, and stir evenly. Add 44g of epoxy ester aqueous dispersion emulsion, and finally add 4.4g of drier, adjust the viscosity with deionized water, and filter to obtain the epoxy ester resin aqueous dispersion emulsion antirust primer.

[0035] Table 1 is the specific formulation of the antirust primer based on the epoxy ester resin aqueous dispersion emulsion. The drier VXW-4940 in the table is a product provided by Solutia; the defoamer T-034 is provided by Shanghai Coatings Research Institute; the dispersant BYK-190 is provided by BYK,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com