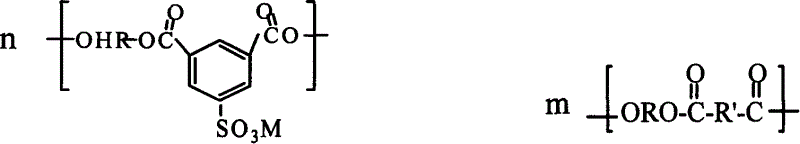

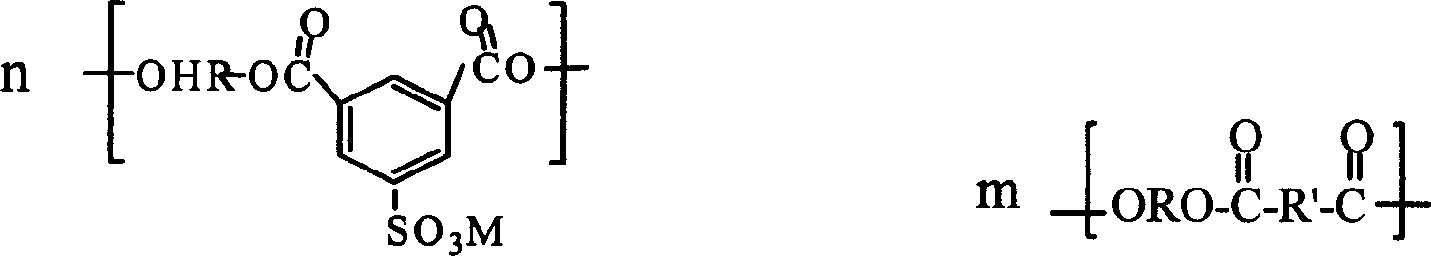

Water dispersible sulfonated polyester polyol and its preparing method

A technology of sulfonated polyester and polyol, applied in the field of sulfonated polyester polyol and its preparation, can solve the problems of unstable performance of water-based polyurethane and many reaction steps, and achieve the effect of superior dispersibility and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 4.5g of 1,4-butanediol, 10g of dimethyl isophthalate-5-sodium sulfonate and 0.0116g of tetrabutyl titanate into a three-necked flask equipped with a fractionation device, and conduct transesterification at 240°C. Then lower the temperature to 140°C, add 24.7g of adipic acid, 21.3g of 1,4-butanediol and 0.0184g of tetrabutyl titanate and zinc acetate mixture, reflux at 160°C for 2 hours, then change to a fractionating device, and separate the water for 2 hours. After 1 hour, blow nitrogen, keep warm at 160, 170, 180, 190, 210, and 220°C for 1 hour respectively, add 0.0184g tetrabutyl titanate equal to the second time and vacuumize at 220°C and 1KPa for 2 hours, Dropped to 140 ° C and discharged, the obtained white waxy solid was detected by nuclear magnetic infrared detection data as above, which proved to be the water-dispersible sulfonated polyester polyol of the present invention, wherein R=-CH 2 -CH 2 -CH 2 -CH 2 -, R'=-CH 2 -CH 2 -CH 2 -CH 2 -, relative m...

Embodiment 2

[0023] Add 9.2g of 1,4-butanediol, 10g of dimethyl isophthalate-5-sodium sulfonate and 0.01536g of tetrabutyl titanate into a three-necked flask equipped with a reflux device, and reflux at 180°C for 1 hour. Then lower the temperature to 80°C, add 49.3g of adipic acid, 45.6g of 1,4-butanediol and 0.0379g of tetrabutyl titanate, reflux at 160°C for 1 hour, then change to a fractionation device, separate the water for 2 hours, and pass nitrogen. Incubate at 160, 170, 180, 190, 210, and 220°C for 1 hour, add 0.0379g of tetrabutyl titanate and vacuum at 220°C and 1KPa for 2 hours, drop to 140°C and discharge to obtain a white wax The solid is detected by nuclear magnetic infrared detection data as above, which proves to be the water-dispersible sulfonated polyester polyol of the present invention, wherein R=-CH 2 -CH 2 -CH 2 -CH 2 -, R'=-CH 2 -CH 2 -CH 2 -CH 2 -, Mr=3000, m / n=10.

[0024] Take 1 part of the above product and place it in a three-necked flask, add 1.5 parts ...

Embodiment 3

[0026] Add 41.1g of triethylene glycol, 6g of dimethyl isophthalate-5-sodium sulfonate and 0.0377g of tetrabutyl titanate into a three-necked flask equipped with a reflux device, and perform transesterification at 200°C for 1 hour , then lowered the temperature to 110°C, added 47.4g of adipic acid and 0.0189g of tetrabutyl titanate, refluxed at 160°C for 2 hours, then changed to a fractionation device, separated water for 2 hours, and passed nitrogen, respectively at 160, 170, 180 , 190, 210, and 220°C for 1 hour, add 0.0189g of tetrabutyl titanate and vacuumize at 220°C and 1KPa for 1.5 hours, then drop to 140°C and discharge. , proved to be the water dispersible sulfonated polyester polyol of the present invention, wherein R=-CH 2 -CH 2 -0-CH 2 -CH 2 -0-CH 2 -CH 2 -, R'=-CH 2 -CH 2 -CH 2 -CH 2 -, Mr=5000, m / n=16.

[0027]Take 30g of the above product and 2.7g of isophorone diisocyanate in a three-necked flask, add dropwise a drop of dibutyltin dilaurate, react and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com