Catalyst for esterification deacidification of crude oil and distillate oil and process thereof

A technology of esterification, deacidification, and catalyst, which is applied in the petroleum industry, refining hydrocarbon oil, etc., and can solve problems such as hydrogen consumption, environmental pollution, and high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

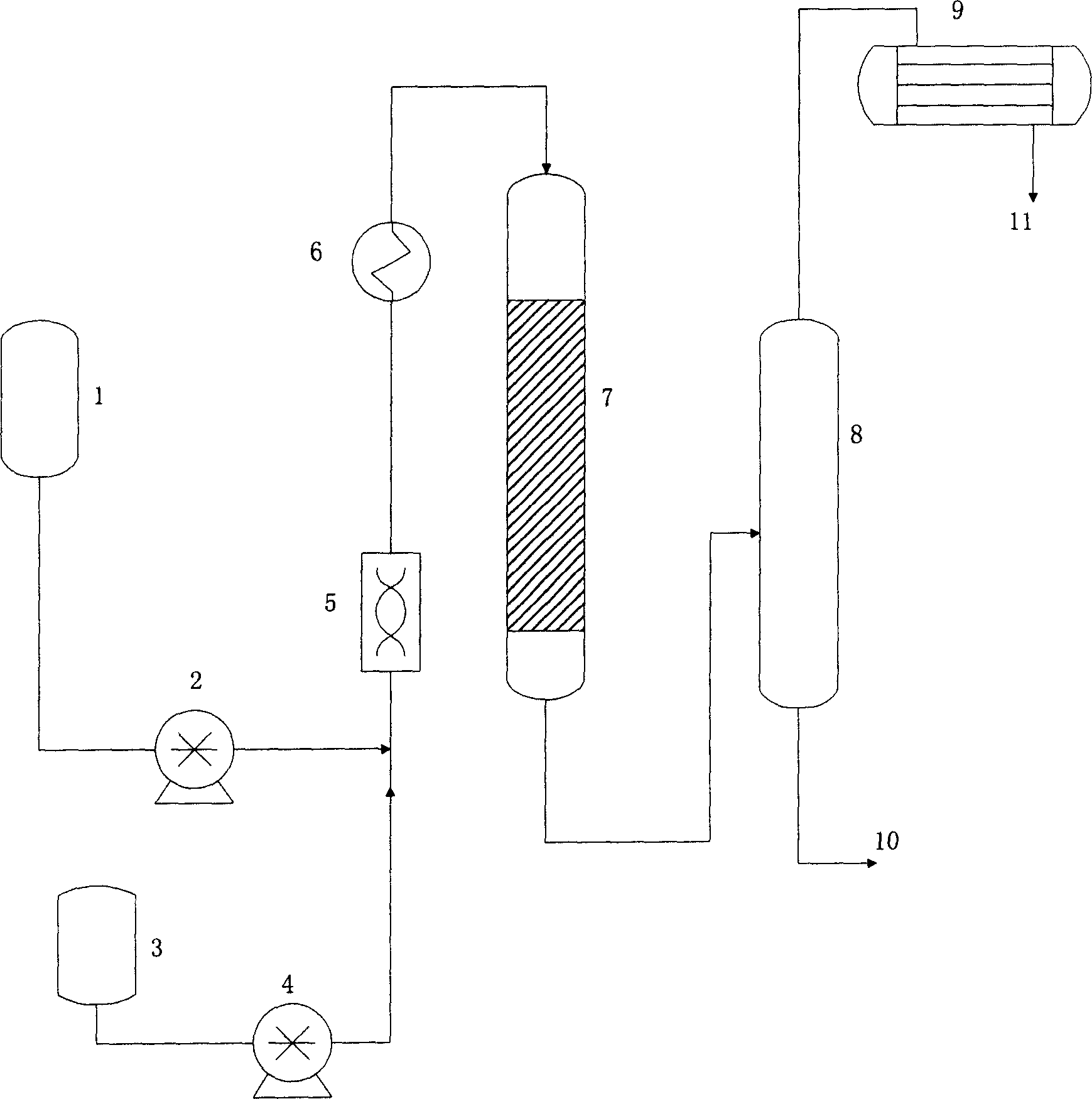

Method used

Image

Examples

Embodiment 1

[0010] In a laboratory fixed-bed reactor, the above-mentioned catalyst is loaded, and the composition of the catalyst is: the carrier is alumina, the active component is Sn, and the content of Sn is 20 (w)%. The inner diameter of the reactor is 26mm and the length is 500mm , the height of catalyzer is 450mm, feeds with metering pump, raw material oil is certain crude oil, and its acid value is 3.9mgKOH / g, and methyl alcohol is esterification deacidification agent, and methyl alcohol accounts for raw material oil 1% (weight), earlier methyl alcohol and The crude oil is mixed well, and then fed with a pump, the reaction temperature of the reactor bed is 250°C, the reaction pressure is 0.2MPa, and the space velocity is 2hr -1 , after stable operation for 4hr, the acid value of deacidified oleic acid was recorded as 0.3mgKOH / g, and the deacidified oil was 92.3%. Unreacted methanol was contained in the deacidified oil, and methanol accounted for 0.6% (weight) of raw oil by distillat...

Embodiment 2

[0013] Using the same reactor as Example 1, the stock oil is a second-line distillate under reduced pressure, with a distillation range of 350-420° C. and an acid value of 3.8 mgKOH / g. Using methanol as an esterification deacidification agent, the consumption accounts for 0.5% of the crude oil. The composition of the catalyst is as follows: the carrier is molecular sieve, the active components are Sn and Zn, accounting for 4.6% (weight) of the catalyst, wherein Sn accounts for 3.1% of the catalyst, and Zn accounts for 1.5% of the catalyst. The bed temperature of the reactor is 270°C, the space velocity is 1, and the reaction pressure is 0.5 MPa. After stable operation, the acid value of the deacidified oil is 0.36 mgKOH / g, and the deacidification rate is 90.5%. Using other carriers such as diatomaceous earth, clay, and silica gel to support Sn and Zn also has good results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com