Quenching oil regeneration method

A quenching oil and weight technology, which is applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of complicated process, complicated additional processing equipment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

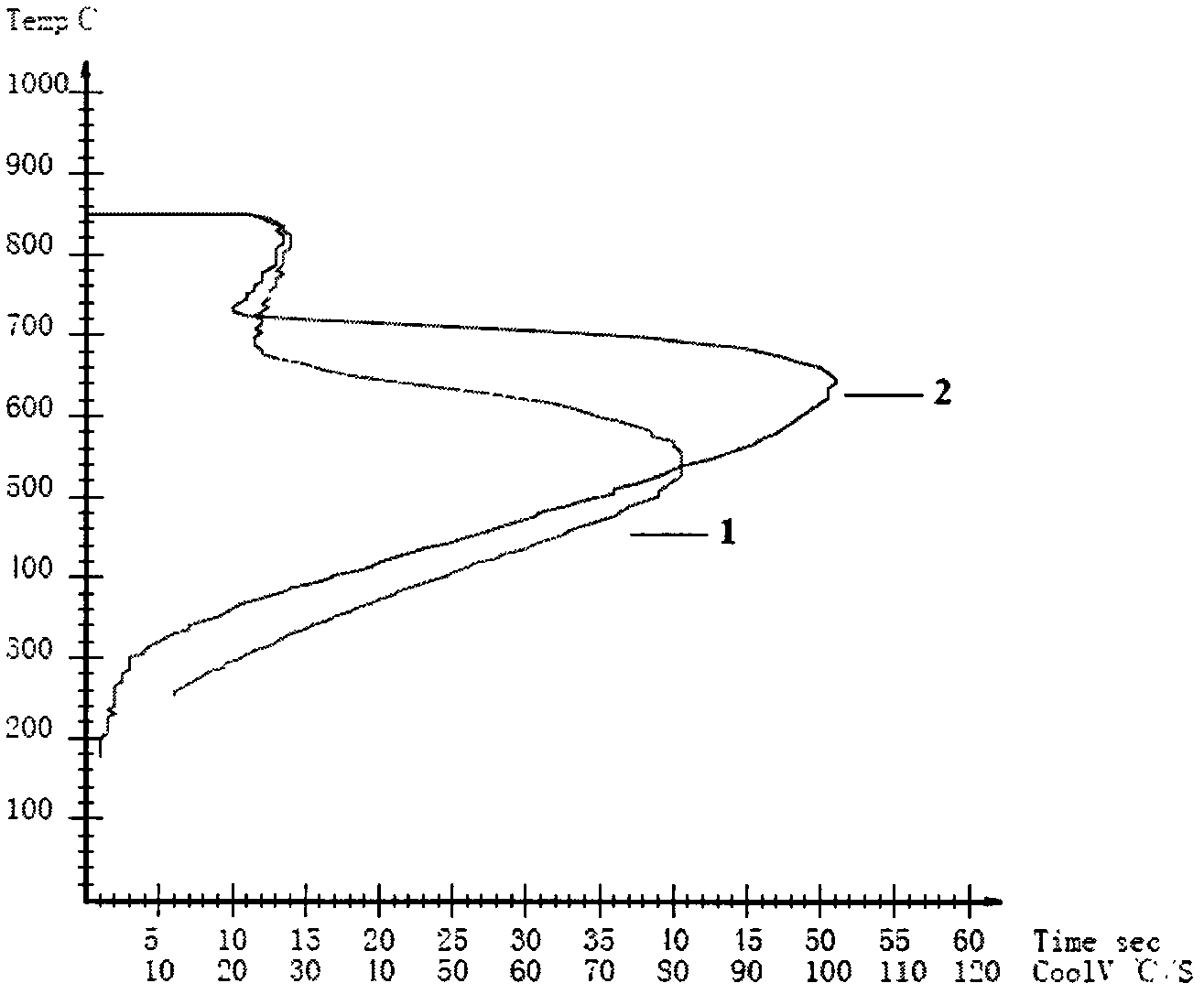

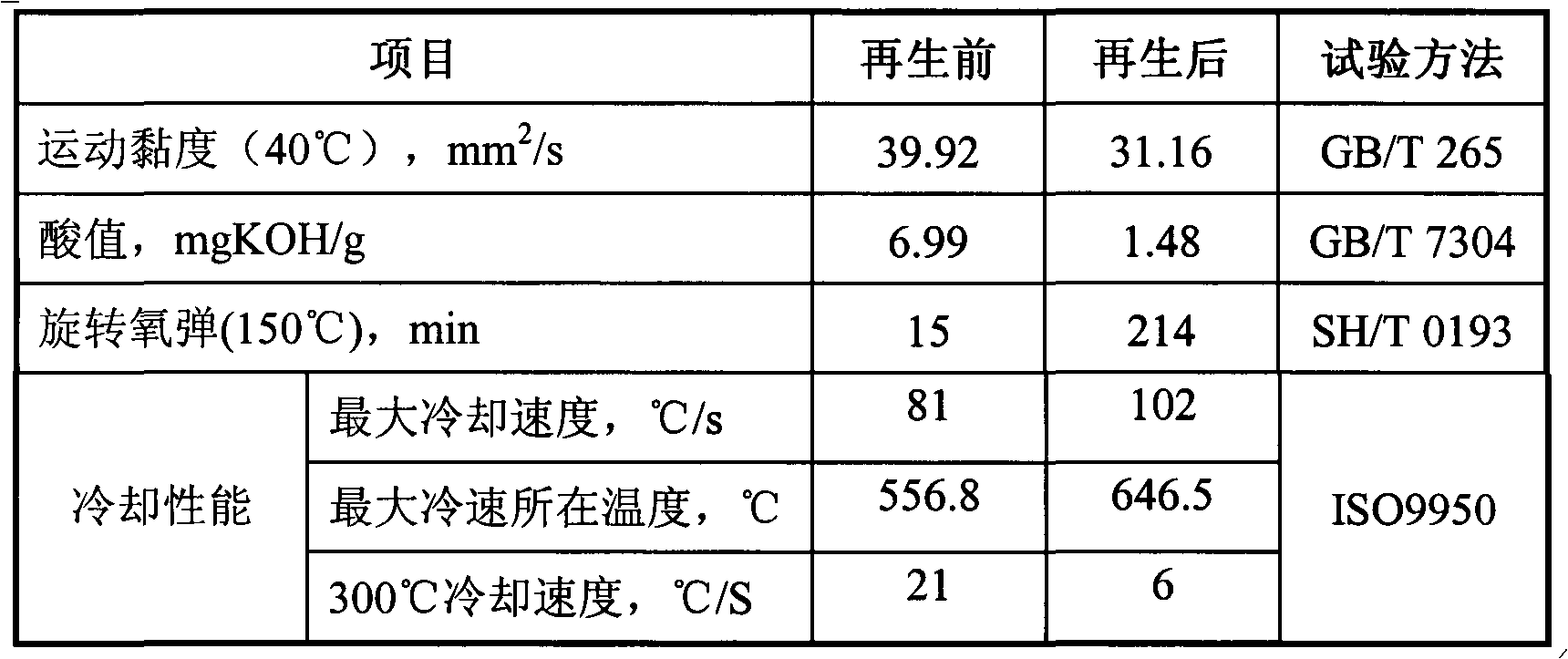

[0025] The quenching oil to be treated is fast and bright quenching oil that has been used for more than two years. The viscosity and acid value increase, and quenching soft spots appear on the workpiece after quenching. It is regenerated, which specifically includes the following steps:

[0026] a) After the quenching oil to be treated is naturally settled, the oil sludge impurities deposited at the bottom of the quenching tank are removed;

[0027] b) adding acid value reducing agent CaO to react with the acidic substance in the oil, the addition amount is 1%, and stirring and reacting at 70°C for 3 hours;

[0028] c) Adsorption and filtration is carried out with activated clay to remove salts and water impurities in the oil; the treatment temperature is 70°C, the treatment time is 2 hours, and the consumption of activated clay is 8%;

[0029] d) After filtering, heat the quenching oil to 90° C. and circulate and stir for 3 hours to remove trace moisture in the quenching oi...

Embodiment 2

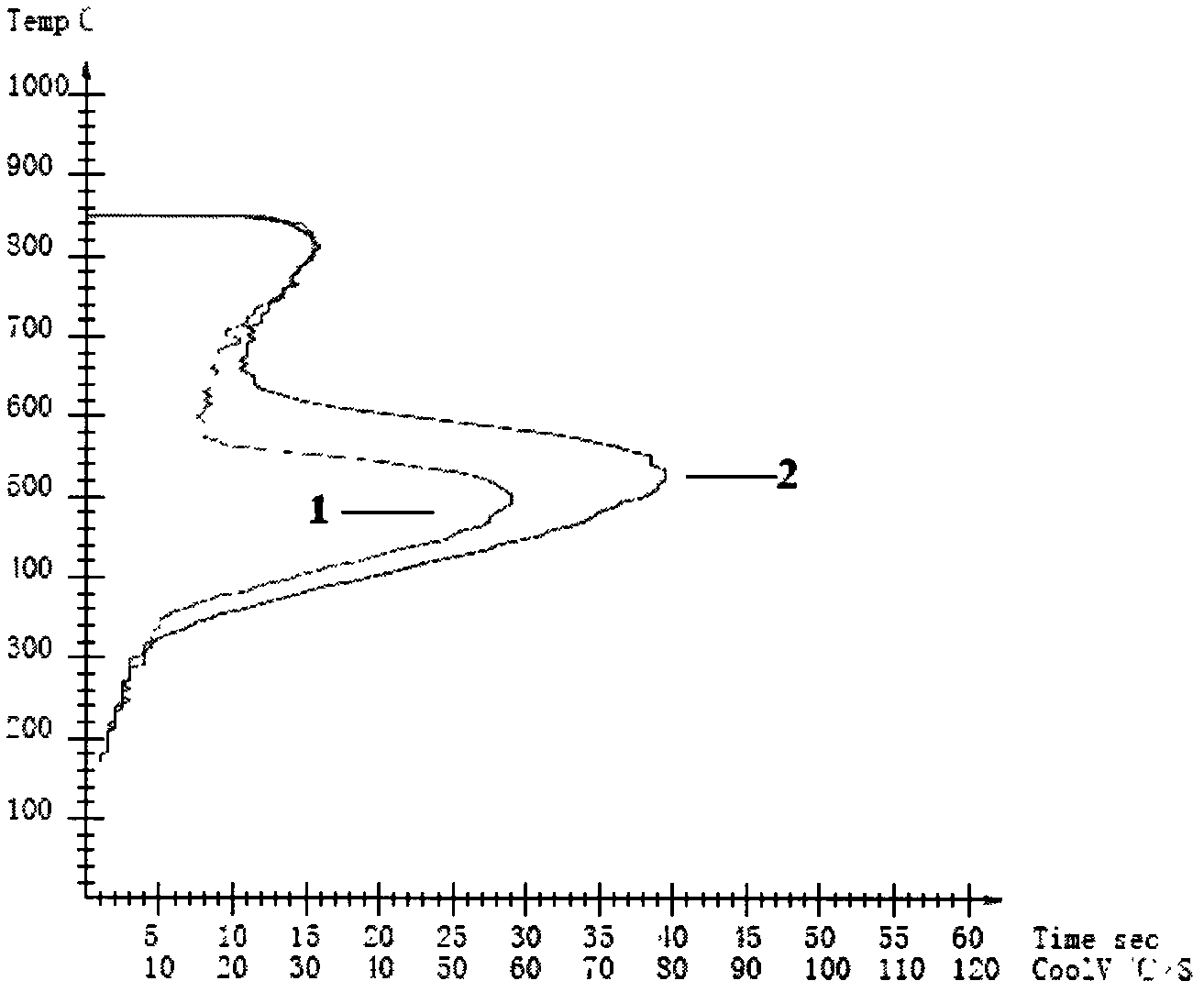

[0036] The quenching oil to be treated is ordinary quenching oil that has been used for many years. The aging phenomenon is obvious, and the performance of some parts cannot meet the technical requirements of heat treatment after quenching and tempering. It is regenerated, which specifically includes the following steps:

[0037] a) After the quenching oil to be treated is filtered through a wire filter screen with a mesh size of 1.0×1.0mm, impurities such as iron oxide and oil sludge in the quenching oil are removed;

[0038] b) Add acid value reducing agent Mg(OH) 2 React with the acidic substances in the oil, add 0.8%, stir and react at 70°C for 2 hours, reduce the acid value of the quenching oil;

[0039] c) Adsorption and filtration with diatomaceous earth to remove salts and water impurities in the oil; the treatment temperature is 70°C, the treatment time is 2 hours, and the amount of diatomite is 10%;

[0040] d) After filtering, heat the quenching oil to 90° C. and ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com