Flue gas discharge subsystem of residential flue gas emission system

A smoke emission and subsystem technology, applied to vertical pipes, building components, fire protection, etc., can solve the problems affecting the fire spread of check valves, lack of sealing devices, and inapplicability, so as to improve the prevention of smoke backflow and construction The effect of convenience and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

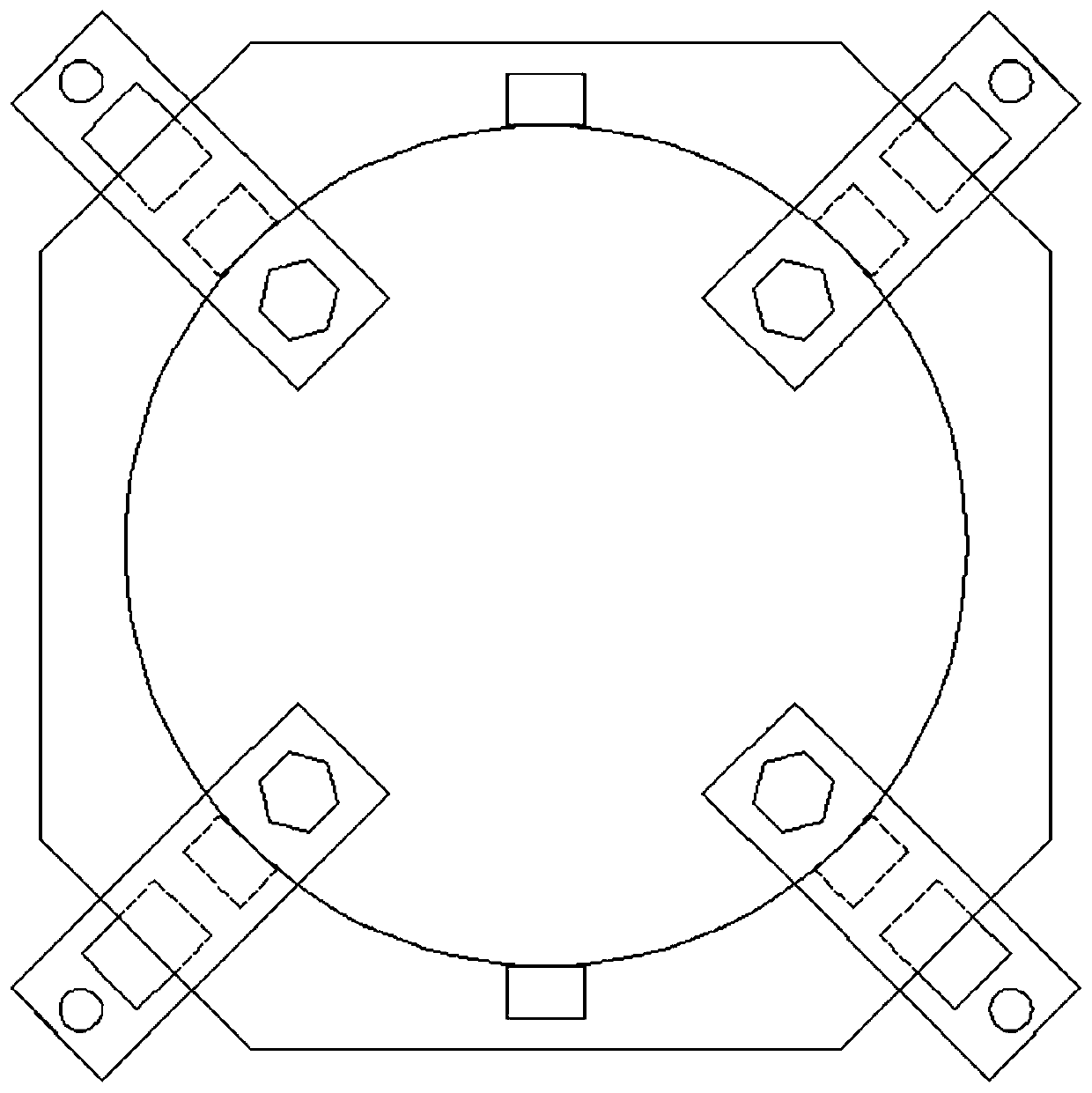

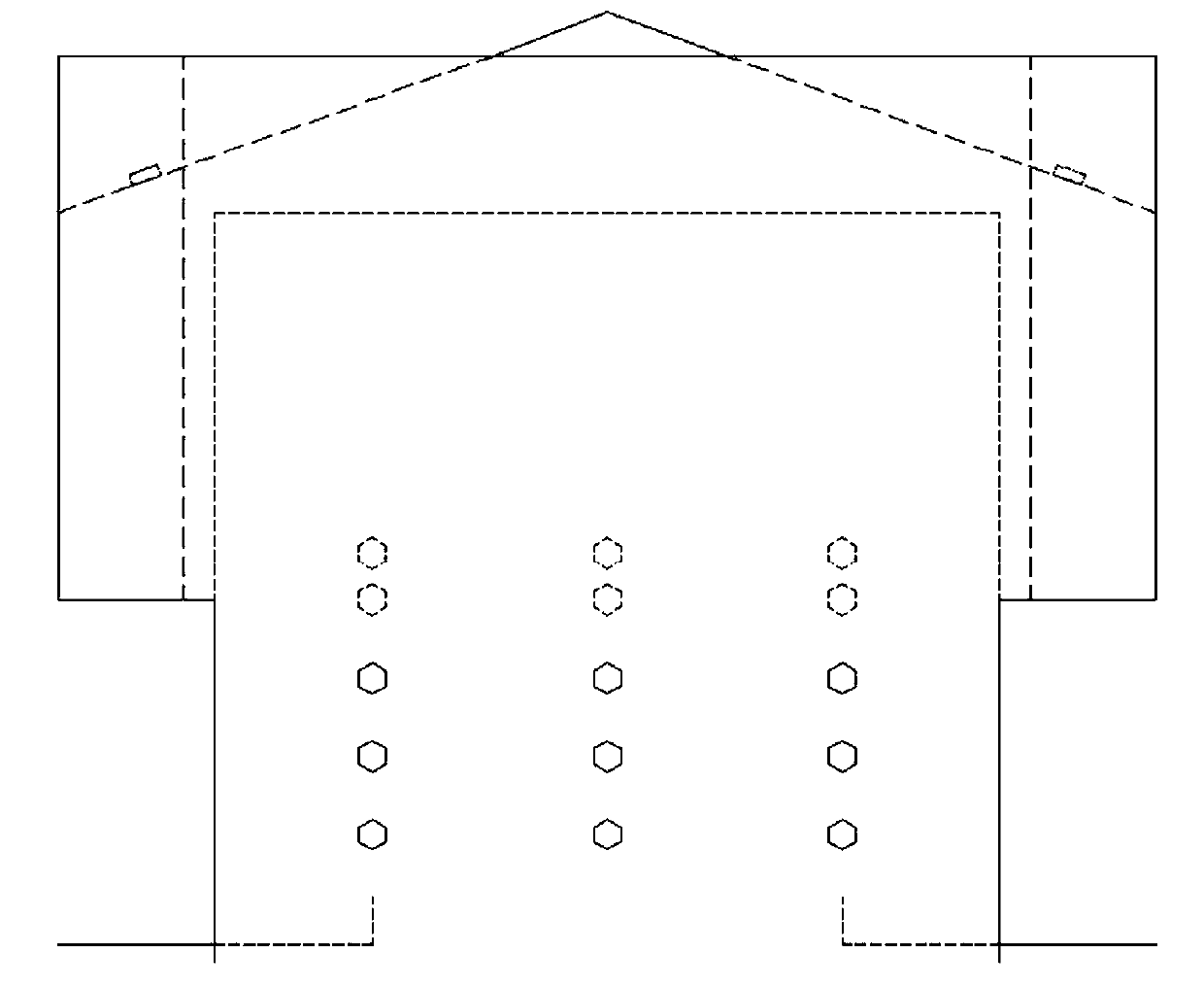

[0030] like Figure 5 and 6 As shown, a residential flue gas discharge system includes a flue gas input subsystem, a flue gas delivery subsystem, and a flue gas output subsystem arranged in sequence, and the junction between the flue gas input subsystem and the flue gas delivery subsystem is set There are fixing holes for placing heat-resistant and fireproof check valves and composite fixtures for fixing the check valves; the flue gas delivery subsystem includes composite flue gas exhaust ducts such as Figure 7 As shown, the composite reserved holes and composite connecting sleeves of cast-in-place slabs are as follows Figure 10 shown;

[0031] The flue gas output subsystem includes a composite cast-in-place roof reserved hole 9, a composite connecting sleeve such as Figure 10 as shown and an inert windshield such as figure 2 and 8 Shown one end is arranged on the support cylinder 13 of building object top, is positioned at described support cylinder other end radial ...

Embodiment 2

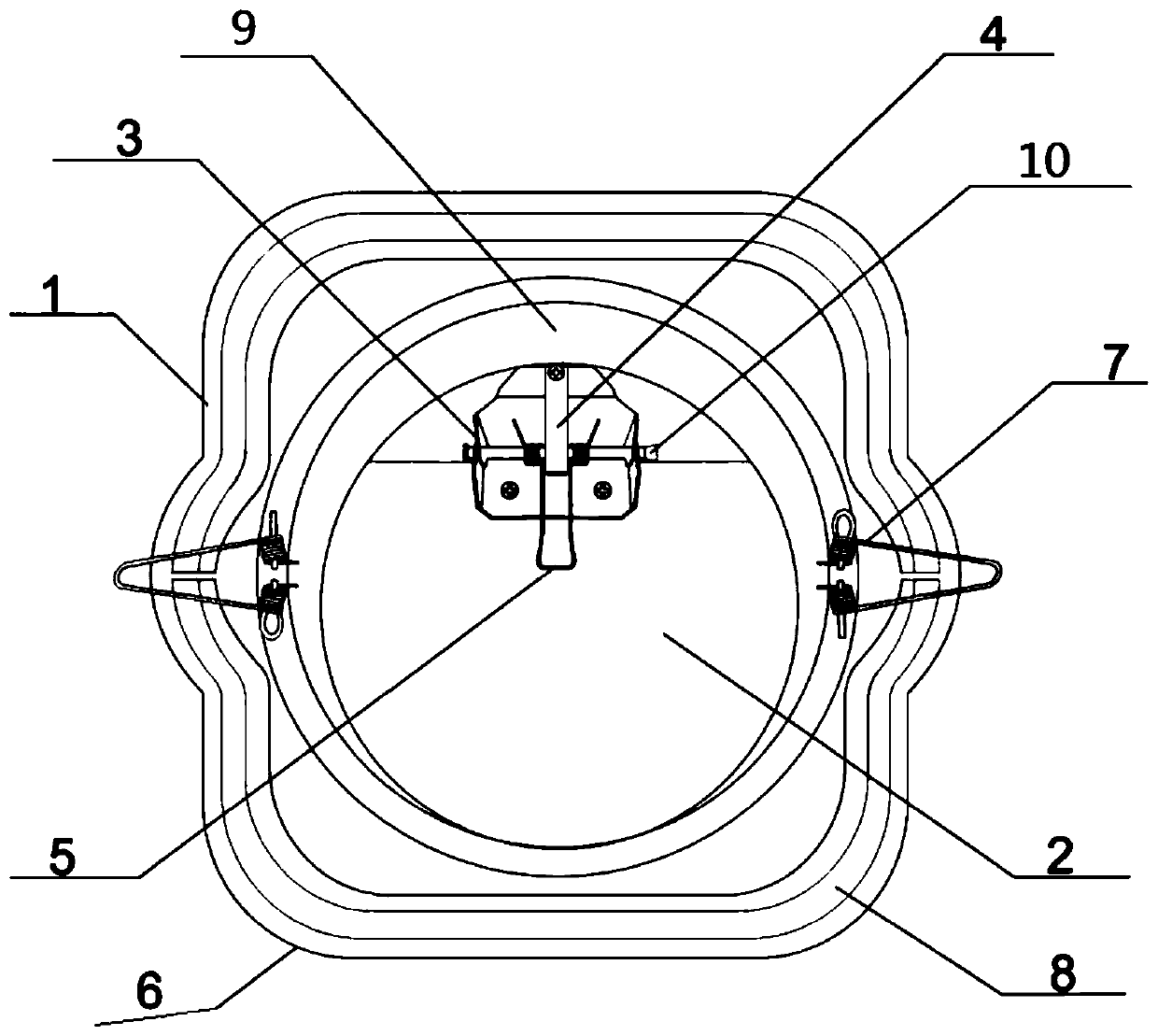

[0037] like figure 1 As shown, the fire check valve in the technical solution of the present invention includes a base 1, a ventilation pipe 9, a hinge 3, a valve plate 2, a temperature sensing plate 4 and an extension spring 5, and the ventilation pipe 9 is installed on the base On the seat 1, the valve sheet 2 is flexibly connected to the ventilation pipe 9 through the hinge 3, the temperature sensing sheet 4 is connected to the hinge 3, and the hinge 3 is provided with a hinge connection. Shaft 10, the extension spring 5 is sleeved on the hinge connecting shaft 10, and a layer of anti-corrosion layer 6 is coated on the base 1.

[0038] The fire check valve also includes a snap ring 7 connected to the base 1 .

[0039] The inner surface of the base 1 is connected with a flame-retardant sealing strip 8, and the shape of the flame-retardant sealing strip 8 is adapted to the shape of the inner surface of the base 1.

Embodiment 3

[0041] Preparation of composite flue gas exhaust duct:

[0042] Composite flue gas exhaust duct of the present invention Made from the following raw materials in parts by weight:

[0043] Aggregate, gypsum, lime calcium powder, toughening agent, interface modifier, flame retardant and foaming agent.

[0044]The aggregate is any one or a mixture of diatomite, slag powder, fly ash, expanded vermiculite, and vitrified microbeads. The gypsum is desulfurized gypsum.

[0045] The toughening agent is any one of calcium carbonate whiskers, potassium carbonate whiskers, and magnesium salt whiskers.

[0046] The interface modifier is a mixture of mica flakes, gelling agent and silicon powder.

[0047] The content ratio of mica sheet, gelling agent and silicon powder in the interface modifier is 3:1:0.02.

[0048] The flame retardant is any one of antimony trioxide, magnesium hydroxide and aluminum hydroxide.

[0049] The blowing agent is sodium lauryl sulfate.

[0050] Flame-ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com