Polycarbonate resin for elastic hand feeling paint, preparation method thereof, and elastic hand feeling paint

A technology of polycarbonate resin and hand-feel paint, applied in polycarbonate coatings, coatings, etc., can solve the problems of high freezing point, weak weather resistance, poor elasticity, etc., and achieve the effect of good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

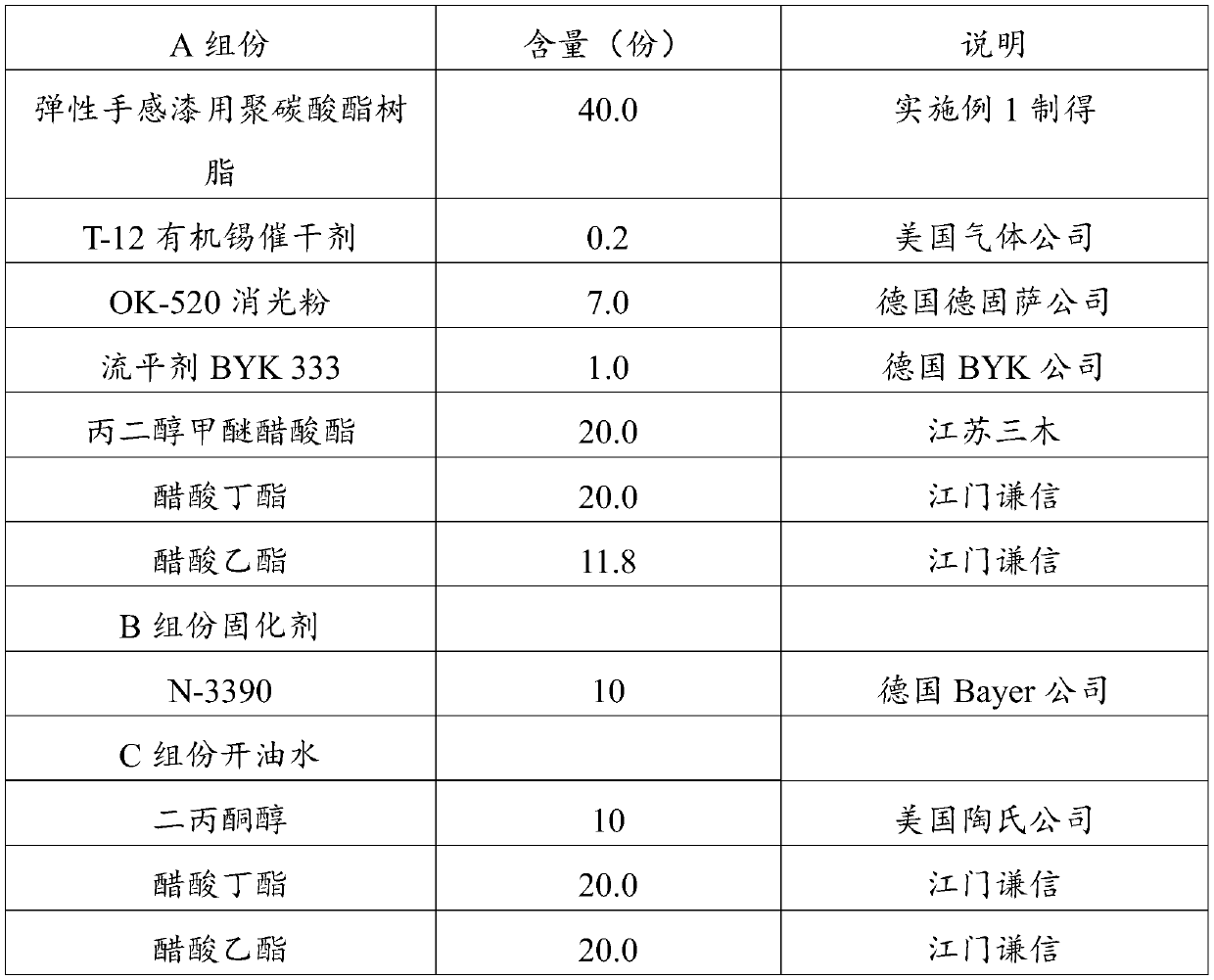

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of polycarbonate resin, and preparation step comprises:

[0029] (1) 40-60 parts of propylene carbonate, 20-30 parts of 1,4 butanediol, 10-20 parts of 3-methyl-1,5-pentanediol, 20-40 parts of butanediol Alkenediol, 0.1-0.5 parts of antioxidant and 0.02-0.1 part of catalyst are put into the reactor, and the temperature is raised;

[0030] (2) The temperature of the reaction kettle material is raised to 240-250°C, and the top temperature of the rectification column of the reaction kettle is not higher than 196°C to steam out the reaction by-products 1 and 2 propylene glycol. internal temperature;

[0031] (3) When the material temperature in the reactor is kept at 250 DEG C, and nitrogen is started to flow into the reactor, the reaction time is 20-30 hours, and when the rectifying column top temperature drops to 190 DEG C, carry out underpressure distillation to obtain polycarbonate resin.

[0032] Prefer...

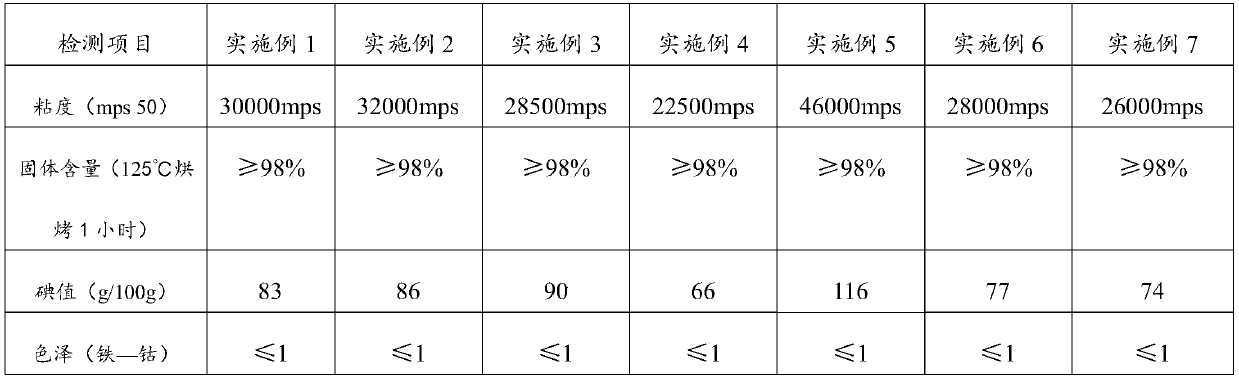

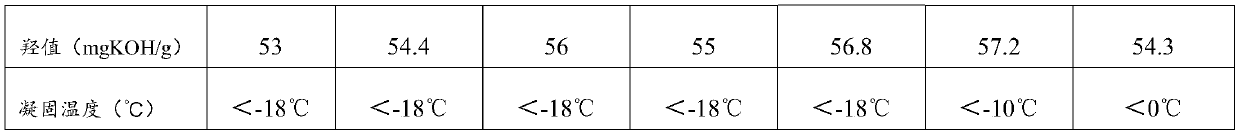

Embodiment 1

[0039] In parts by weight, the raw materials for preparing polycarbonate resin for elastic handle paint include:

[0040] 40 parts of propylene carbonate;

[0041] 1. 20 parts of 4-butanediol;

[0042] 30 parts of butylene glycol;

[0043] 20 parts of 3-methyl-1,5-pentanediol;

[0044] Sodium methoxide 0.02 part;

[0045] 2. 0.4 part of 6 di-tert-butyl-4-methylphenol.

[0046] Adopt above-mentioned raw material to prepare polycarbonate resin for elastic handle paint, preparation method comprises:

[0047] (1) 40 parts of propylene carbonate, 20 parts of 1,4 butanediol, 20 parts of 3-methyl-1,5-pentanediol, 30 parts of butylene glycol, 0.4 parts of 2 , 6 di-tert-butyl-4-methylphenol and 0.02 parts of sodium methoxide are dropped into the reactor, and the temperature is raised;

[0048] (2) The temperature of the reactor material is raised to 240-250°C, and the top temperature of the rectification column of the reactor is not higher than 196°C to steam out the reaction by-...

Embodiment 2

[0051] The raw materials of this embodiment and the polycarbonate resin used in the preparation of elastic hand paint in embodiment 1 are basically the same, the difference is that the catalyst used in embodiment 2 is magnesium-aluminum hydrotalcite, and the catalyst used in embodiment 1 is sodium methylate. Its preparation method is the same as that of Example 1, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com