A kind of water-based self-drying acrylic acid modified epoxy ester resin emulsion and preparation method thereof

A technology of epoxy ester resin and acrylic acid, which is applied in the direction of coating, etc., can solve the problems of low reactivity of emulsifier and decrease of paint film performance, and achieve the effects of easy polymerization heat, polymerization heat diffusion, and avoid performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

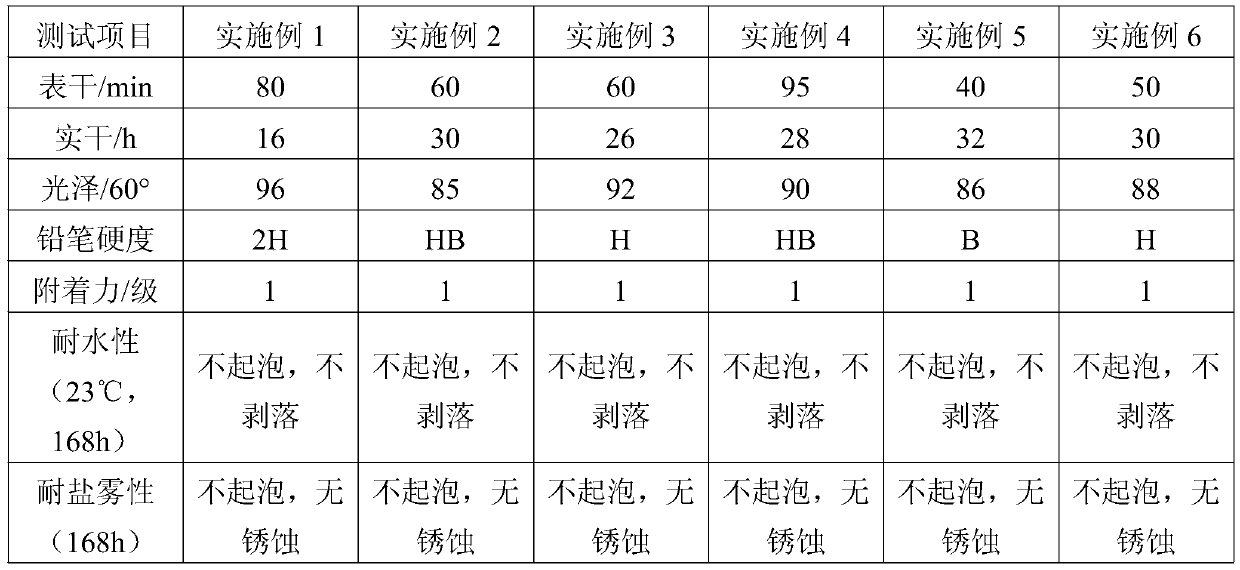

Examples

Embodiment 1

[0039] a. Preparation of reactive emulsifier I: (1) add 892.7g of deionized water to 14.1g of ammonia water and stir, and heat to 50°C after completely dissolving to form a uniform aqueous solution; (2) slowly add 93.2g of linolenic acid, and react Until the solid is completely dissolved and the pH is 7-9.

[0040] b. Preparation of reactive emulsifier II: (1) Heat 200g of epoxy resin E-51 to 110°C, pass through nitrogen protection, slowly add 141.8g of linolenic acid and 2g of DMP-30 to react; (2) react to When the acid value of the system is less than 5mgKOH / g, cool down to 100°C, add 36.7g of acrylic acid; (3) add 100g of maleic anhydride when the acid value of the system is less than 5mgKOH / g; (4) react until the acid value of the system is 115-125mgKOH / g Cool down to 60° C. and add 42.9 g of ammonia water and 478 g of deionized water to adjust the pH to 7-9.

[0041] c. Preparation of epoxy ester: (1) Heat 300g of epoxy resin E-51 to 110°C, pass through nitrogen protecti...

Embodiment 2

[0044] a. Preparation of reactive emulsifier I: (1) Add 900g of deionized water to 26.6g of triethylamine and stir, and heat to 60°C after completely dissolving to form a uniform aqueous solution; (2) Slowly add 36.7g of oleic acid, 36.7 g linolenic acid, react until the solids are completely dissolved and the pH is 7-9.

[0045] b. Preparation of reactive emulsifier II: (1) Heat 266.5g of epoxy resin E-12 to 130°C, pass through nitrogen protection, slowly add 22.2g of oleic acid, 22.2g of linoleic acid and 4.1g of N,N- Dimethylbenzylamine reacts; (2) cool down to 100°C when the acid value of the system is less than 5mgKOH / g, and add 13.7g methacrylic acid; (3) add 78.3g horsepower when the acid value of the system is less than 5mgKOH / g to acid anhydride; (4) react until the acid value of the system is 105-115mgKOH / g, cool down to 90°C, add 96.9g triethylamine and 500g deionized water, and adjust the pH to 7-9.

[0046] c. Preparation of epoxy ester: (1) Heat 530.4g of epoxy ...

Embodiment 3

[0049] a. Preparation of reactive emulsifier I: (1) Add 890g of deionized water to 26.7g of N,N-dimethylethanolamine and stir, and heat to 60°C after completely dissolving to form a uniform aqueous solution; (2) Slowly add 55.5 g dehydrated ricinoleic acid, 27.8g linolenic acid, and react until the solids are completely dissolved and the pH is 7-9.

[0050] b. Preparation of reactive emulsifier II: (1) Heat 161.8g of epoxy resin E-54 to 115°C, pass through nitrogen protection, slowly add 81g of dehydrated ricinoleic acid, 40.5g of linolenic acid and 2.8g of triethanolamine to carry out Reaction; (2) cool down to 95°C when the acid value of the system is less than 5mgKOH / g, and add 37.6g methacrylic acid; (3) add 85.7g maleic anhydride when the acid value of the system is less than 5mgKOH / g; (4) When the acid value of the system is 115-125mgKOH / g, cool down to 60°C, add 93.4g N,N-dimethylethanolamine and 500g deionized water, and adjust the pH to 7-9.

[0051] c. Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com