Synthesis process for air-drying waterborne polyurethane and dispersion thereof

A water-based polyurethane and synthetic process technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems that are rarely reported, and achieve the effects of accelerating moisture volatilization, wide sources, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

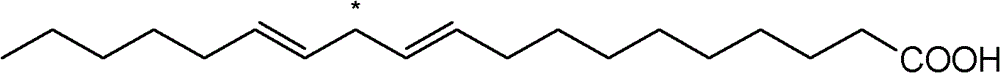

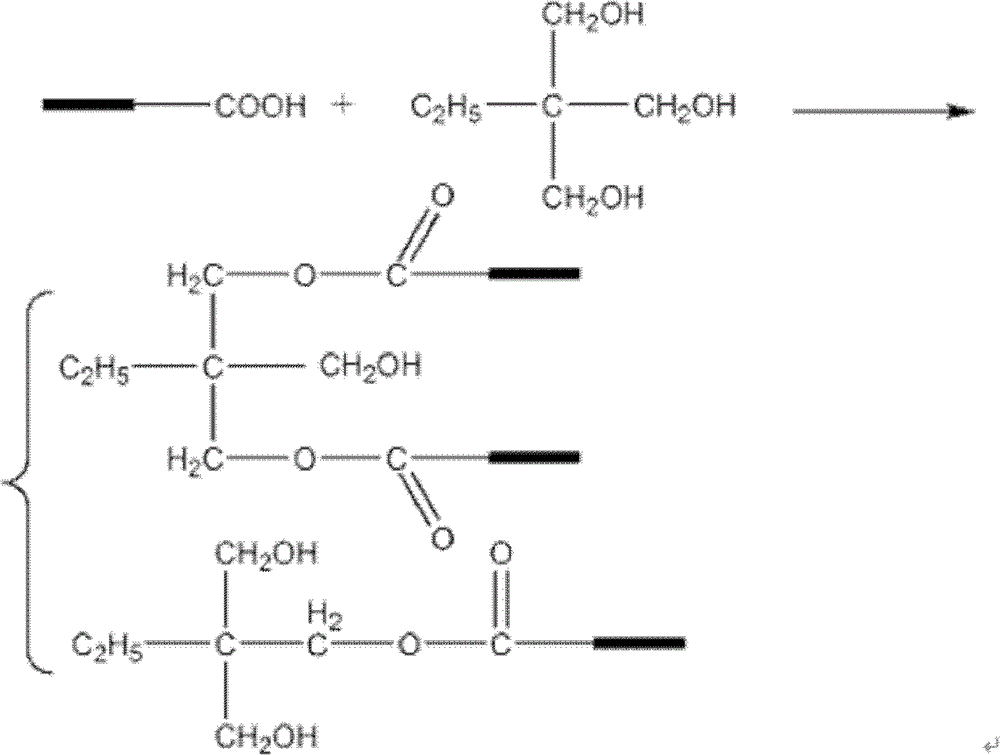

[0023] In a four-necked reaction flask equipped with a stirrer, thermometer, water separator and nitrogen inlet, add linoleic acid and trimethylolpropane, the molar ratio of linoleic acid and trimethylolpropane is 3:2, toluene Reflux, react at 100-120°C under nitrogen gas for 5 hours, and dehydrate the obtained solution at a temperature of 110°C and a vacuum of 0.9 MPa for 2 hours to obtain a chain extender B containing a dry oil structure. In addition, add 50 grams of polyε-caprolactone diol with a molecular weight of 2000 and 20 grams of isophorone diisocyanate into a three-necked reaction flask equipped with a thermometer, a stirrer, and a reflux condenser, stir evenly, and gradually heat up to 90°C React for 2 hours, cool down to 60°C, add 4 grams of hydrophilic chain extender A, namely dimethylolpropionic acid, and 15 grams of chain extender B containing dry oil structure, keep warm for 5 hours, and gradually increase the viscosity as the reaction progresses. Add acetone ...

Embodiment 2

[0025] The synthesis process was the same as in Example 1, except that the poly(epsilon)-caprolactone diol with a molecular weight of 2000 was replaced with polytetrahydrofuran diol with a molecular weight of 2000, and the obtained product was a 42% air-drying water-based polyurethane dispersion.

Embodiment 3

[0027] The synthesis process was the same as in Example 1, except that the poly(ε-caprolactone) diol with a molecular weight of 2000 was replaced with polyoxyethylene diol with a molecular weight of 2000, and the obtained product was a 42% air-drying water-based polyurethane dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com