Bio-based epoxy resin pouring sealant and preparation method thereof

A technology based on epoxy resin and epoxy resin, which is applied in the field of bio-based epoxy resin potting glue and its preparation, can solve the problems of low molecular chain flexibility, large internal stress, and high chemical crosslinking density, so as to broaden the range of raw materials Good source, good flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A bio-based epoxy resin potting glue, the preparation method of which comprises the following steps:

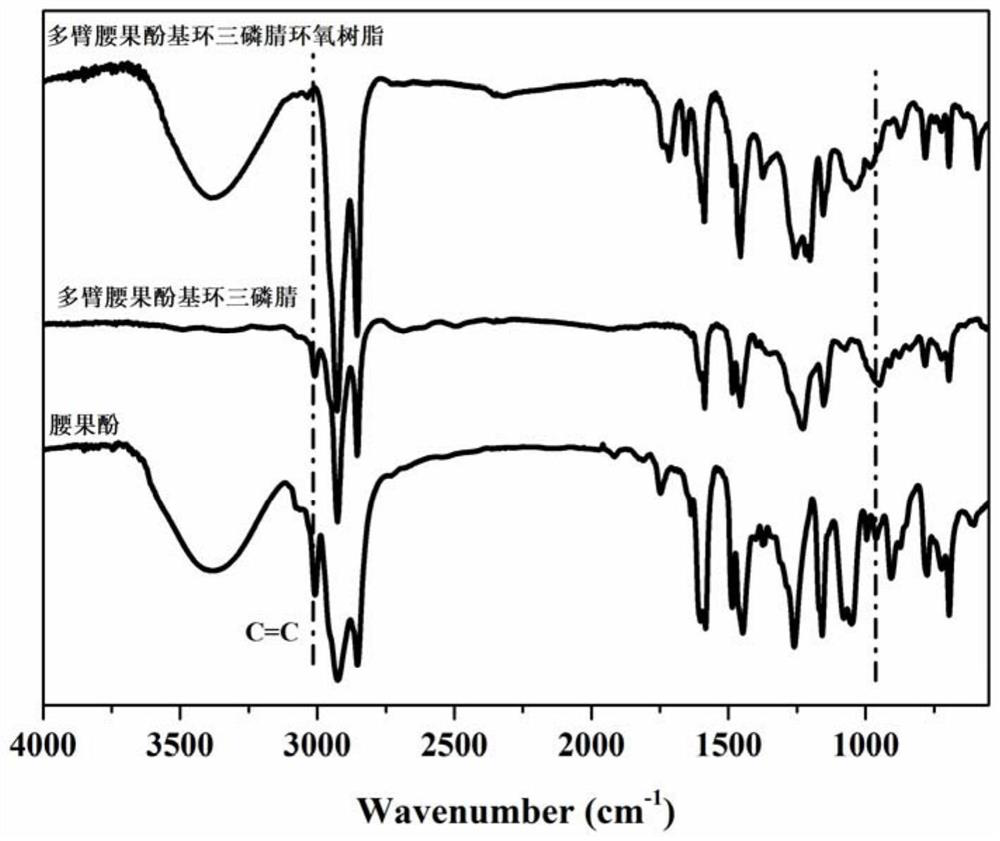

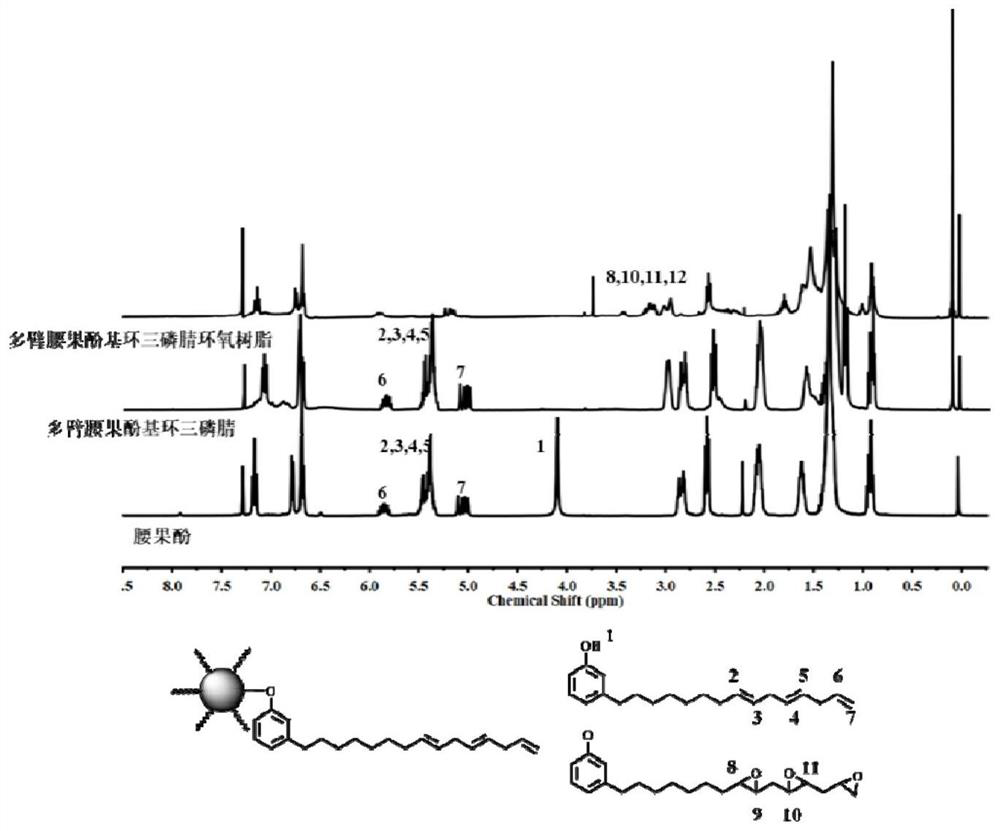

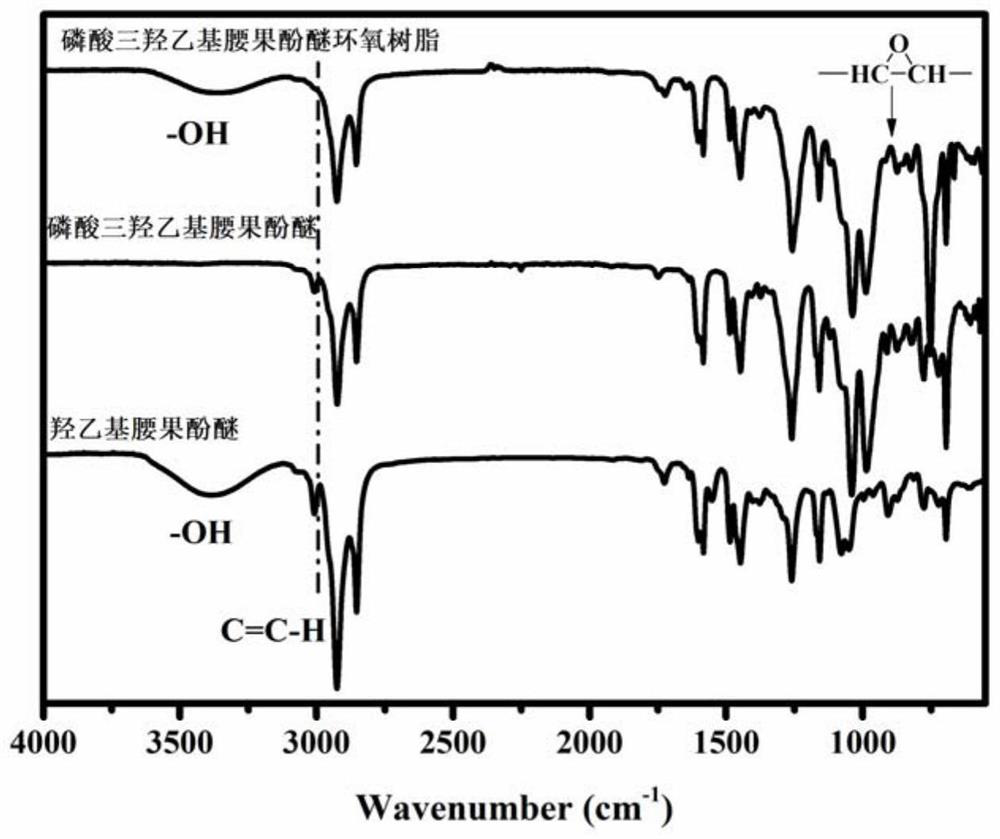

[0043] (1) Synthesis of multi-arm cardanol-based cyclotriphosphazene epoxy resin (ECC)

[0044] Mix 100 mL of 1,4-dioxane, 54.00 g (0.18 mol) of cardanol and 18.22 g (0.18 mol) of triethylamine, and add 10.43 g (0.03 mol of ) 1,4-dioxane solution of hexachlorocyclotriphosphazene in 300 mL, after dropping, the system was heated to 98°C and stirred and refluxed for 48 hours; after the reaction was completed, cooled to room temperature, suction filtered, and the filtrate was concentrated and dried to obtain Brown-yellow oily liquid, namely multi-arm cardanol-based cyclotriphosphazene resin (CC);

[0045] In a three-necked round-bottomed flask equipped with a precision thermometer and mechanically stirred, 190 g of CC was added, the temperature was stabilized at 50 ° C, and 20 g of formic acid (FA) and 180 g of hydrogen peroxide (50%) were slowly added dropwise at the sam...

Embodiment 2

[0057] A bio-based epoxy resin potting glue, the preparation method of which comprises the following steps:

[0058] (1) Synthesis of multi-arm cardanol-based cyclotriphosphazene epoxy resin (ECC)

[0059] Mix 100 mL of 1,4-dioxane, 45.00 g (0.15 mol) of cardanol and 15.18 g (0.15 mol) of triethylamine, and add 10.43 g (0.03 mol of ) 1,4-dioxane solution of hexachlorocyclotriphosphazene in 300 mL, after dropping, the system was heated to 98°C and stirred and refluxed for 48 hours; after the reaction was completed, cooled to room temperature, suction filtered, and the filtrate was concentrated and dried to obtain Brown-yellow oily liquid, namely multi-arm cardanol-based cyclotriphosphazene resin (CC);

[0060] In a three-necked round-bottomed flask equipped with a precision thermometer and mechanically stirred, 166.5 grams of CC was added, and the temperature was stabilized at 50°C, and 15g of formic acid (FA) and 135g of hydrogen peroxide (50%) were slowly added dropwise at t...

Embodiment 3

[0069] A bio-based epoxy resin potting glue, the preparation method of which comprises the following steps:

[0070] (1) Synthesis of multi-arm cardanol-based cyclotriphosphazene epoxy resin (ECC)

[0071] Mix 100 mL of 1,4-dioxane, 54.00 g (0.18 mol) of cardanol and 18.22 g (0.18 mol) of triethylamine, and add 20.86 g (0.06 mol of ) 1,4-dioxane solution of hexachlorocyclotriphosphazene in 300 mL, after dropping, the system was heated to 98°C and stirred and refluxed for 48 hours; after the reaction was completed, cooled to room temperature, suction filtered, and the filtrate was concentrated and dried to obtain Brown-yellow oily liquid, namely multi-arm cardanol-based cyclotriphosphazene resin (CC);

[0072] In a three-necked round-bottomed flask equipped with a precision thermometer and mechanically stirred, 125 grams of CC was added, the temperature was stabilized at 50 °C, and 10 g of formic acid (FA) and 90 g of hydrogen peroxide (50%) were slowly added dropwise at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com