High-toughness epoxy resin adhesive and preparation method thereof

A technology of epoxy resin glue and high toughness, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve problems such as easy cracking, achieve the effect of low cost, wide source of raw materials, and improved ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

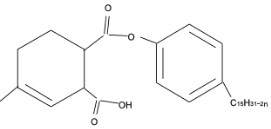

Image

Examples

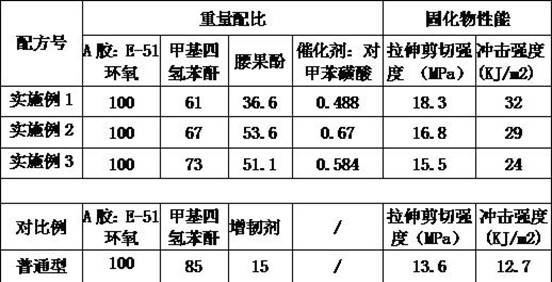

Embodiment 1

[0020] Example 1: B glue methyltetrahydrophthalic anhydride, cashew phenol and catalyst selection mass ratio of 1: 0.6: 8 ‰ in the reactor mixed uniformly, heating and heating, temperature control at 150 ° C, reaction time of 12h, the catalyst is sulfonic acid compounds, specifically toluenesulfonic acid, to obtain cashew phenol modified methyltetrahydrophthalic anhydride compound and methyltetrahydrophthalic anhydride, by mixing with A glue, its performance test.

Embodiment 2

[0021] Example 2: methyltetrahydrophthalic anhydride, cashew phenol and catalyst selected mass ratio of 1: 0.8: 1% in the reactor mixed uniformly, heating and heating, temperature control at 150 ° C, reaction time of 12h, the catalyst is a sulfonic acid compound, specifically to toluenesulfonic acid, to obtain cashew phenol modified methyltetrahydrophthalic anhydride compound and methyltetrahydrophthalic anhydride, by mixing with A glue, its performance test.

Embodiment 3

[0022] Example 3: methyltetrahydrophthalic anhydride, cashew phenol and catalyst selection mass ratio of 1: 0.7: 8 ‰ in the reactor mixed uniformly, heating and heating, temperature control at 150 ° C, reaction time of 12h, the catalyst is a sulfonic acid compound, specifically to toluenesulfonic acid, to obtain cashew phenol modified methyltetrahydrophthalic anhydride compound and methyltetrahydrophthalic anhydride, by mixing with A glue, its performance test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com