Thermal-insulation coating and preparation method thereof

A thermal insulation coating and graphene technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of performance degradation and inability to be used as thermal insulation materials, etc., to achieve excellent thermal insulation performance, excellent self-drying performance, and excellent moisture resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A heat-insulating coating, comprising by weight components: 5 parts of light calcium carbonate, 8 parts of modified graphene, 1 part of polyvinyl acetate, 3 parts of phenolic resin, 2 parts of alkyd resin, 2 parts of sodium tripolyphosphate 0.8 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 3 parts of hydroxypropyl methylcellulose, 10 parts of absolute ethanol, 2 parts of nano silicon dioxide, 10 parts of ethyl acetate, and 8 parts of water.

[0023] The preparation method of described thermal insulation coating, comprises the following steps:

[0024] Step 1, adding light calcium carbonate, polyvinyl acetate, phenolic resin and alkyd resin to absolute ethanol, stirring and mixing evenly at a stirring speed of 160 rpm to obtain a mixed solution 1;

[0025] Step 2, adding sodium tripolyphosphate, sodium fatty alcohol polyoxyethylene ether sulfate and hydroxypropyl methylcellulose into water, heating and stirring for 15 minutes at a heating temperature of 50...

Embodiment 2

[0029] A heat-insulating coating, comprising by weight components: 6 parts of light calcium carbonate, 10 parts of modified graphene, 2 parts of polyvinyl acetate, 4 parts of phenolic resin, 4 parts of alkyd resin, 3 parts of sodium tripolyphosphate 1 part, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 3 parts of hydroxypropyl methylcellulose, 13 parts of absolute ethanol, 3 parts of nano silicon dioxide, 15 parts of ethyl acetate, and 10 parts of water.

[0030] The preparation method of described thermal insulation coating, comprises the following steps:

[0031] Step 1, adding light calcium carbonate, polyvinyl acetate, phenolic resin and alkyd resin to absolute ethanol, stirring and mixing evenly at a stirring speed of 165 rpm to obtain a mixed solution 1;

[0032] Step 2, adding sodium tripolyphosphate, sodium fatty alcohol polyoxyethylene ether sulfate and hydroxypropyl methylcellulose into water, heating and stirring for 16 minutes at a heating temperatu...

Embodiment 3

[0036] A heat-insulating coating, comprising by weight components: 8 parts of light calcium carbonate, 12 parts of modified graphene, 2 parts of polyvinyl acetate, 5 parts of phenolic resin, 6 parts of alkyd resin, 3 parts of sodium tripolyphosphate 1.6 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of hydroxypropyl methylcellulose, 17 parts of absolute ethanol, 4 parts of nano silicon dioxide, 18 parts of ethyl acetate, and 12 parts of water.

[0037] The preparation method of described thermal insulation coating, comprises the following steps:

[0038] Step 1, adding light calcium carbonate, polyvinyl acetate, phenolic resin and alkyd resin to absolute ethanol, stirring and mixing evenly at a stirring speed of 170 rpm to obtain a mixed solution 1;

[0039] Step 2, adding sodium tripolyphosphate, sodium fatty alcohol polyoxyethylene ether sulfate and hydroxypropyl methylcellulose into water, heating and stirring for 20 minutes at a heating temperature of...

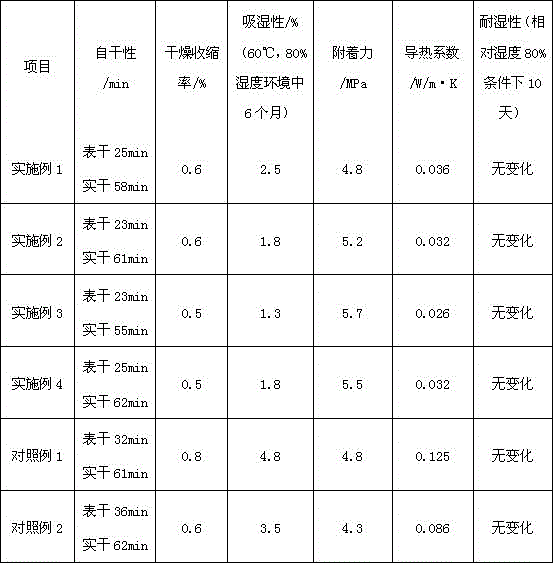

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com