Polycarbonate resin for elastic hand paint and preparation method thereof, and elastic hand paint

A technology of polycarbonate resin and hand paint, applied in polycarbonate coatings, coatings, etc., can solve problems such as high hardness, poor elasticity, and weak weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

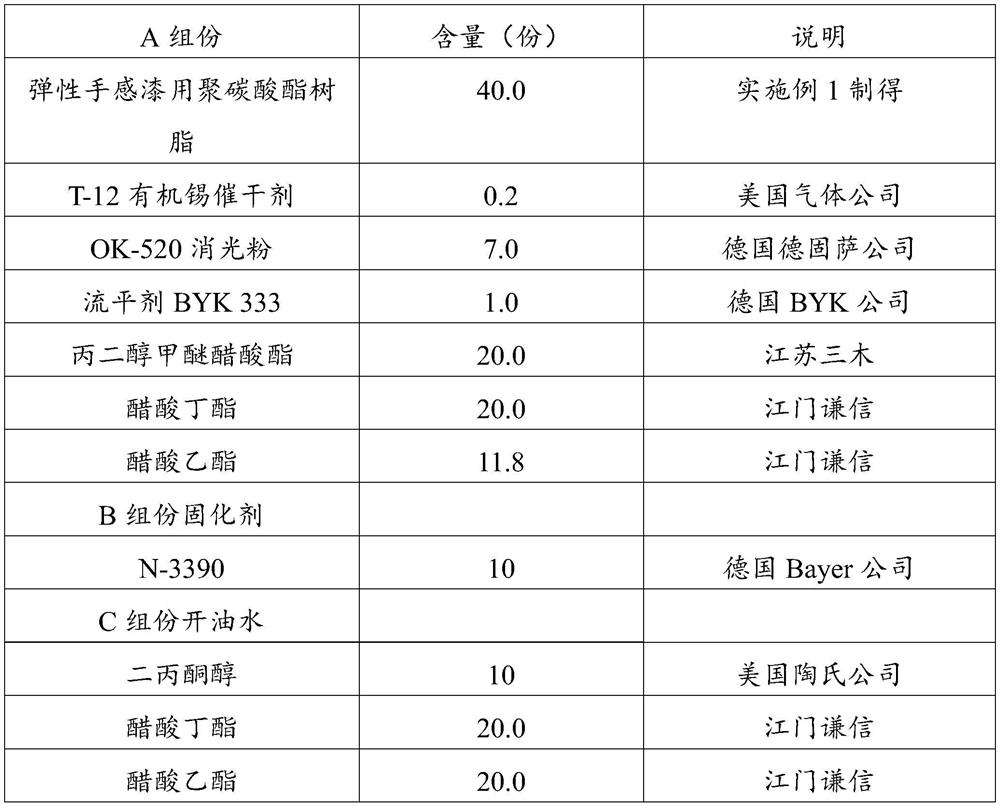

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the polycarbonate resin, the preparation steps comprising:

[0029] (1) 40-60 parts of propylene carbonate, 20-30 parts of 1, 4 butanediol, 10-20 parts of 3-methyl-1, 5-pentanediol, 20-40 parts of butane ethylene glycol, 0.1-0.5 part of antioxidant and 0.02-0.1 part of catalyst are put into the reaction kettle, and the temperature is raised;

[0030] (2) the reaction kettle material is heated to 240-250 ℃, and the reaction kettle distillation column top temperature is not higher than 196 ℃ to steam out the reaction by-products 1 and 2 propylene glycol, along with the by-products 1 and 2 propylene glycol steam, the reaction kettle is raised internal temperature;

[0031] (3) when the temperature of material in the reactor is kept at 250 ℃, and start to lead nitrogen in the reactor, the reaction times is 20-30 hours, and when the temperature of the top of the rectifying column drops to 190 ℃, underpressure disti...

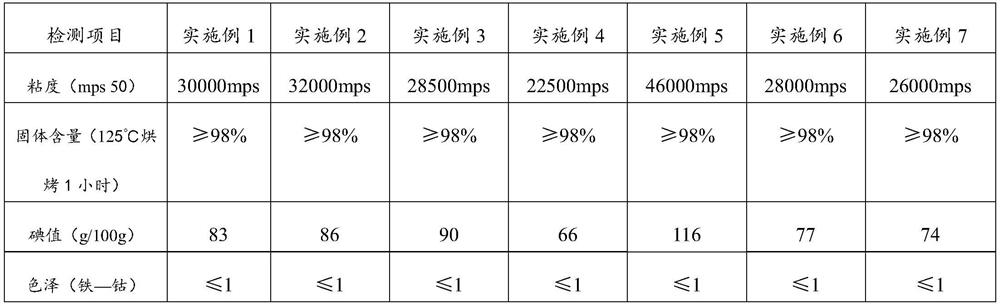

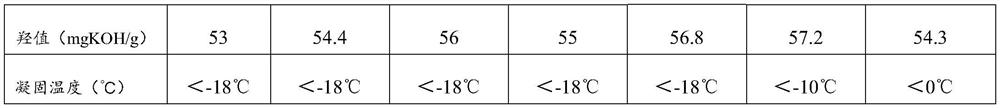

Embodiment 1

[0039] In parts by weight, the raw materials for preparing the polycarbonate resin for elastic touch paint include:

[0040] 40 parts of propylene carbonate;

[0041] 1. 20 parts of 4-butanediol;

[0042] 30 parts of butylene glycol;

[0043] 20 parts of 3-methyl-1,5-pentanediol;

[0044] 0.02 part of sodium methoxide;

[0045] 2.6 Di-tert-butyl-4-methylphenol 0.4 part.

[0046] Using the above-mentioned raw materials to prepare polycarbonate resin for elastic hand-feel paint, the preparation method includes:

[0047] (1) 40 parts of propylene carbonate, 20 parts of 1, 4 butanediol, 20 parts of 3-methyl-1, 5-pentanediol, 30 parts of butene diol, 0.4 parts of 2 , 6 di-tert-butyl-4-methylphenol and 0.02 part of sodium methoxide drop into the reactor, and heat up;

[0048] (2) The temperature of the reaction kettle material is raised to 240-250°C, and the reaction kettle distillation column top temperature is not higher than 196°C to steam out the reaction by-products 1 and...

Embodiment 2

[0051] This example is basically the same as the raw material for preparing polycarbonate resin for elastic hand paint in Example 1, the difference is that the catalyst used in Example 2 is magnesium-aluminum hydrotalcite, while the catalyst used in Example 1 is sodium methoxide. The preparation method is the same as that in Example 1, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com