Emulsifiable oily medium oil solvent type alkyd resin and preparation method thereof

An alkyd resin and solvent-based technology, which is applied in the field of emulsifiable oily medium-oil solvent-based alkyd resin and its preparation, can solve the problems of poor acid and alkali resistance of the resin, unstable paint film, poor stability, etc., and achieve good adhesion , Improve hydrophilicity, resin hardness and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

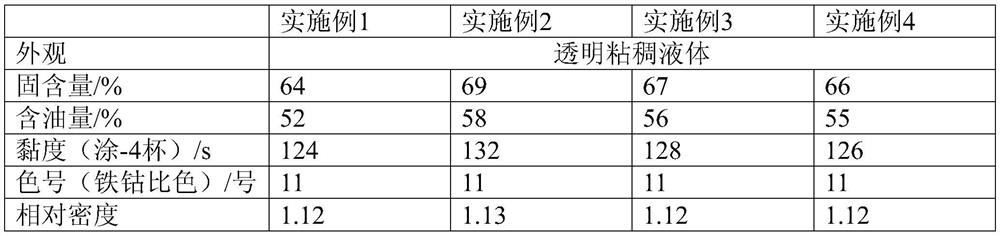

Examples

Embodiment 1

[0046] An emulsifiable oily medium-oil solvent-type alkyd resin, consisting of the following raw materials: 40 kg of acrylate modified alkyd resin, 15 kg of polyethylene glycol modified epoxy resin, 30 kg of butyl glycol ether and 20 kg of deionized water;

[0047] Described acrylate modified alkyd resin is prepared according to the following steps:

[0048]Add fatty acid, sorbitol, trimellitic anhydride and methyl methacrylate into the reactor, mix well, heat up to 160°C, stir for 1 hour, cool down to 100°C, dropwise add the mixture of acrylate and initiator, dropwise Control the temperature of the reaction system not to be higher than 120°C during the addition, keep the reaction at 100°C for 2 hours after the dropwise addition, and lower the temperature by 20°C to obtain an acrylate-modified alkyd resin;

[0049] The fatty acid is castor oil;

[0050] The acrylate is butyl acrylate;

[0051] Described initiator is azobisisobutyronitrile;

[0052] Wherein the mass ratio of...

Embodiment 2

[0061] An emulsifiable oily medium-oil solvent-type alkyd resin, consisting of the following raw materials: 50 kg of acrylate modified alkyd resin, 25 kg of polyethylene glycol modified epoxy resin, 40 kg of ethylene glycol butyl ether and 30 kg of deionized water;

[0062] Described acrylate modified alkyd resin is prepared according to the following steps:

[0063] Add fatty acid, sorbitol, trimellitic anhydride and methyl methacrylate into the reactor, mix well and heat up to 180°C, stir for 3 hours, cool down to 120°C, add the mixture of acrylate and initiator dropwise, drop Control the temperature of the reaction system not to be higher than 120°C during the addition, keep the reaction at 120°C for 4 hours after the dropwise addition, and lower the temperature by 30°C to obtain an acrylate-modified alkyd resin;

[0064] The fatty acid is linseed oil;

[0065] The acrylate is isooctyl acrylate;

[0066] Described initiator is benzoyl peroxide;

[0067] Wherein the mass ...

Embodiment 3

[0076] An emulsifiable oily medium-oil solvent-type alkyd resin, consisting of the following raw materials: 42kg of acrylate modified alkyd resin, 22kg of polyethylene glycol modified epoxy resin, 32kg of butyl glycol ether and 28kg of deionized water;

[0077] Described acrylate modified alkyd resin is prepared according to the following steps:

[0078] Add fatty acid, sorbitol, trimellitic anhydride and methyl methacrylate into the reactor, mix well and heat up to 165°C, stir for 1.5 hours, cool down to 105°C, add the mixture of acrylate and initiator dropwise, drop Control the temperature of the reaction system not to be higher than 120°C during the addition, and keep the reaction at 100-105°C for 2.5 hours after the dropwise addition, and then lower the temperature to 24°C to obtain an acrylate-modified alkyd resin;

[0079] The fatty acid is obtained by mixing castor oil and linoleic acid in a mass ratio of 1:1;

[0080] The acrylate is butyl acrylate;

[0081] Describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com