Polymer modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and modified asphalt, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of difficult emulsification and difficult storage and transportation of polymer modified asphalt, and achieve excellent bonding performance and easy emulsification , Good storage and transportation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

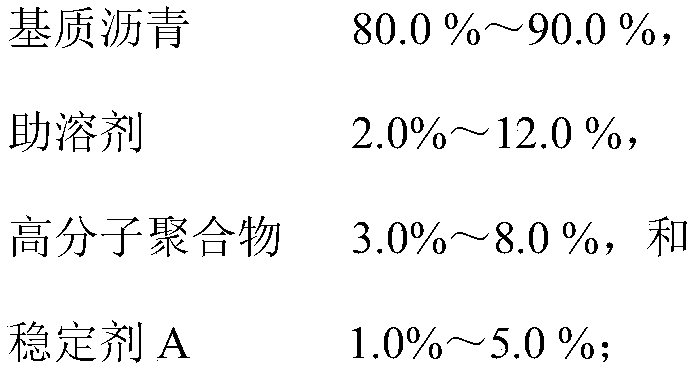

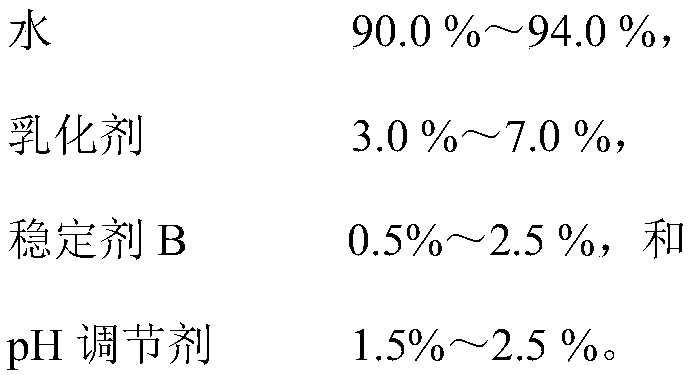

Method used

Image

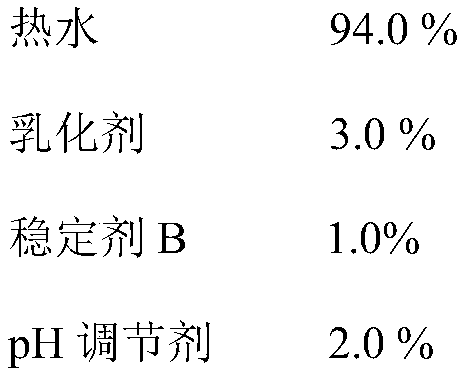

Examples

Embodiment 1

[0042] ① Preparation of polymer modified asphalt

[0043] 110 road asphalt 89.0%, its asphaltene content is 1.5%, sulfur content is 0.3%;

[0044] Furfural extract oil 2%, its aromatic content is 85%, kinematic viscosity at 100°C is 50mm 2 / s;

[0045] Styrene-Butadiene-Styrene Block Copolymer SBS T6302H 8%

[0046] Stabilizer A 1.0%

[0047] Wherein stabilizer A comprises,

[0049] Benzoyl Peroxide 0.25%

[0050] Aluminum oxide 0.25%

[0051] The preparation method of the polymer modified asphalt of the present embodiment comprises the following steps,

[0052] Step 1, preheating 89.0% No. 110 road asphalt and 2% furfural extraction oil to 130°C;

[0053] Step 2. Mix the preheated No. 110 road asphalt and furfural oil, heat to 160°C, add 8% styrene-butadiene-styrene block copolymer SBS T6302H, stir and shear for 30 minutes, and prepare get the first mixture;

[0054] Step 3. Add 1.0% stabilizer A to the first mixture, heat it to 180° C.,...

Embodiment 2

[0069] ① Preparation of polymer modified asphalt

[0070] Road No. 90 asphalt 87.0%, its asphaltene content is 0.1%, sulfur content is 1.0%;

[0071] Furfural extract oil 5%, its aromatic content is 50%, kinematic viscosity at 100°C is 70mm 2 / s;

[0072] Styrene-Butadiene-Styrene Block Copolymer SBS T6302H 5%

[0073] Stabilizer A 3.0%

[0074] Wherein stabilizer A comprises,

[0075] Concentrated sulfuric acid 99.5%

[0076] Benzoyl Peroxide 0.25%

[0077] Aluminum oxide 0.25%

[0078] The preparation method of the polymer modified asphalt of the present embodiment comprises the following steps,

[0079] Step 1, preheating 87.0% No. 90 road asphalt and 5% furfural extraction oil to 140°C;

[0080]Step 2. Mix the preheated No. 90 road asphalt and furfural oil, heat to 170°C, add 5% styrene-butadiene-styrene block copolymer SBS T6302H, stir and shear for 30 minutes, and prepare get the first mixture;

[0081] Step 3: Add 3.0% of stabilizer A to the first mixture, hea...

Embodiment 3

[0095] ① Preparation of polymer modified asphalt

[0096] 70 road asphalt 87.5%, its asphaltene content is 1.5%, sulfur content is 1.0%

[0097] Furfural extract oil 5%, its aromatic content is 75%, kinematic viscosity at 100°C is 63mm 2 / s;

[0098] Styrene Butadiene Rubber SBR K1585 2%, Styrene-Butadiene-Styrene Block Copolymer SBS T6302H 3%

[0099] Stabilizer A 2.5%

[0100] Wherein stabilizer A comprises,

[0101] Oleum 99.5%

[0102] tert-Butyl Benzoyl Peroxide 0.25%

[0104] The preparation method of the polymer modified asphalt of the present embodiment comprises the following steps,

[0105] Step 1, preheating to 150 ℃ with 87.5% No. 70 road asphalt and 5% furfural extraction oil;

[0106] Step 2. Mix the preheated No. 70 road asphalt and furfural oil, heat to 170°C, add 2% styrene-butadiene rubber SBR K1585 and 3% styrene-butadiene-styrene block copolymer SBS After T6302H, stir and shear for 20min to obtain the first mixture;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com