Hardmask composition and method of forming pattern using the hardmask composition

a composition and composition technology, applied in the field of hardmask composition and a method of forming patterns using the hardmask composition, can solve the problems of increasing the height of the photoresist layer, the difficulty of providing a fine pattern having a desirable profile, and the limited hardmask pattern, so as to achieve the effect of improving the etching resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

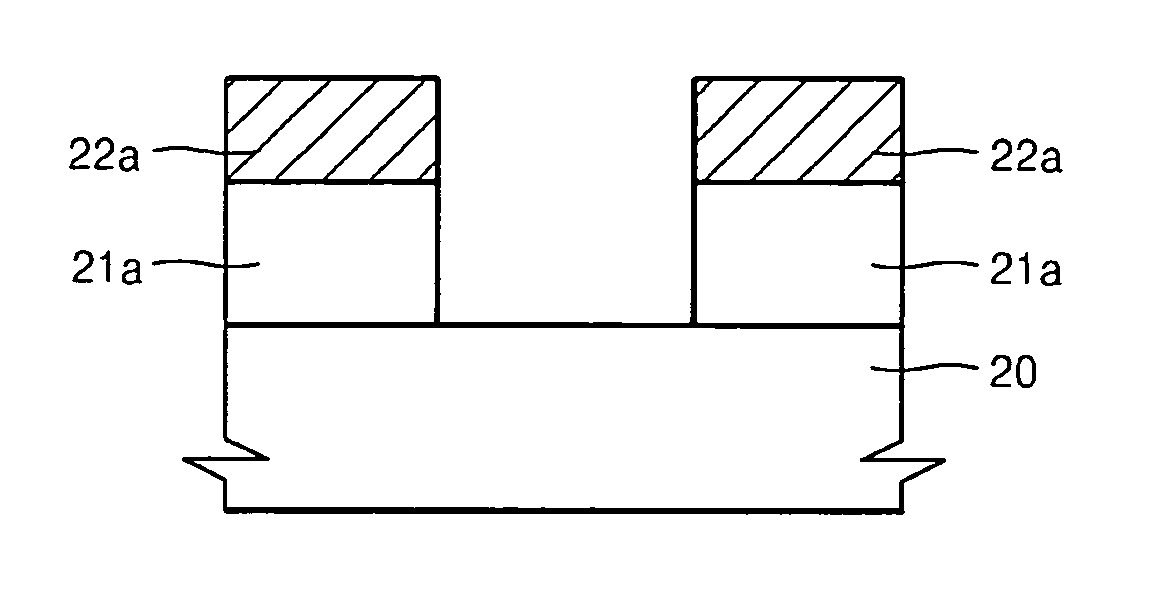

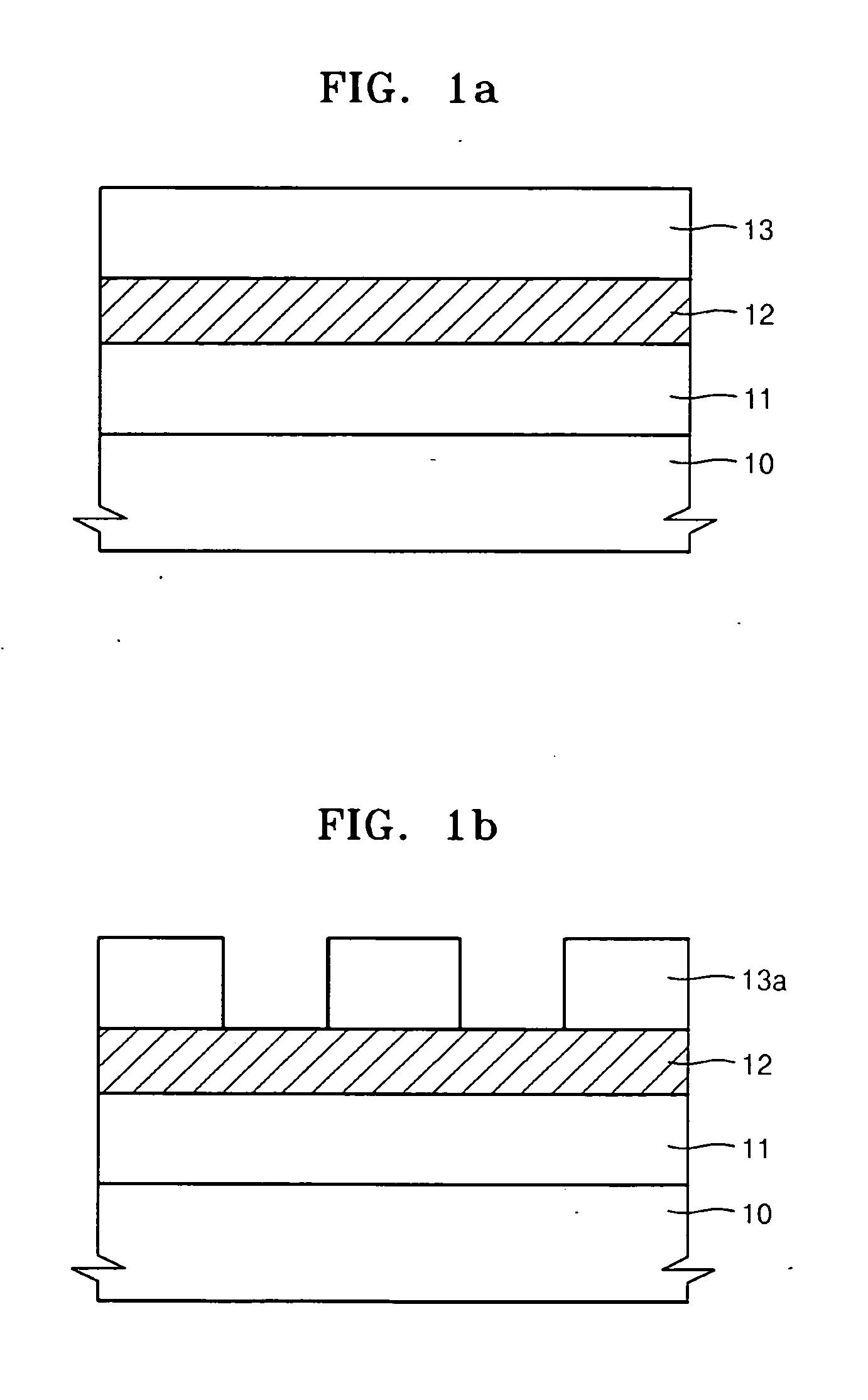

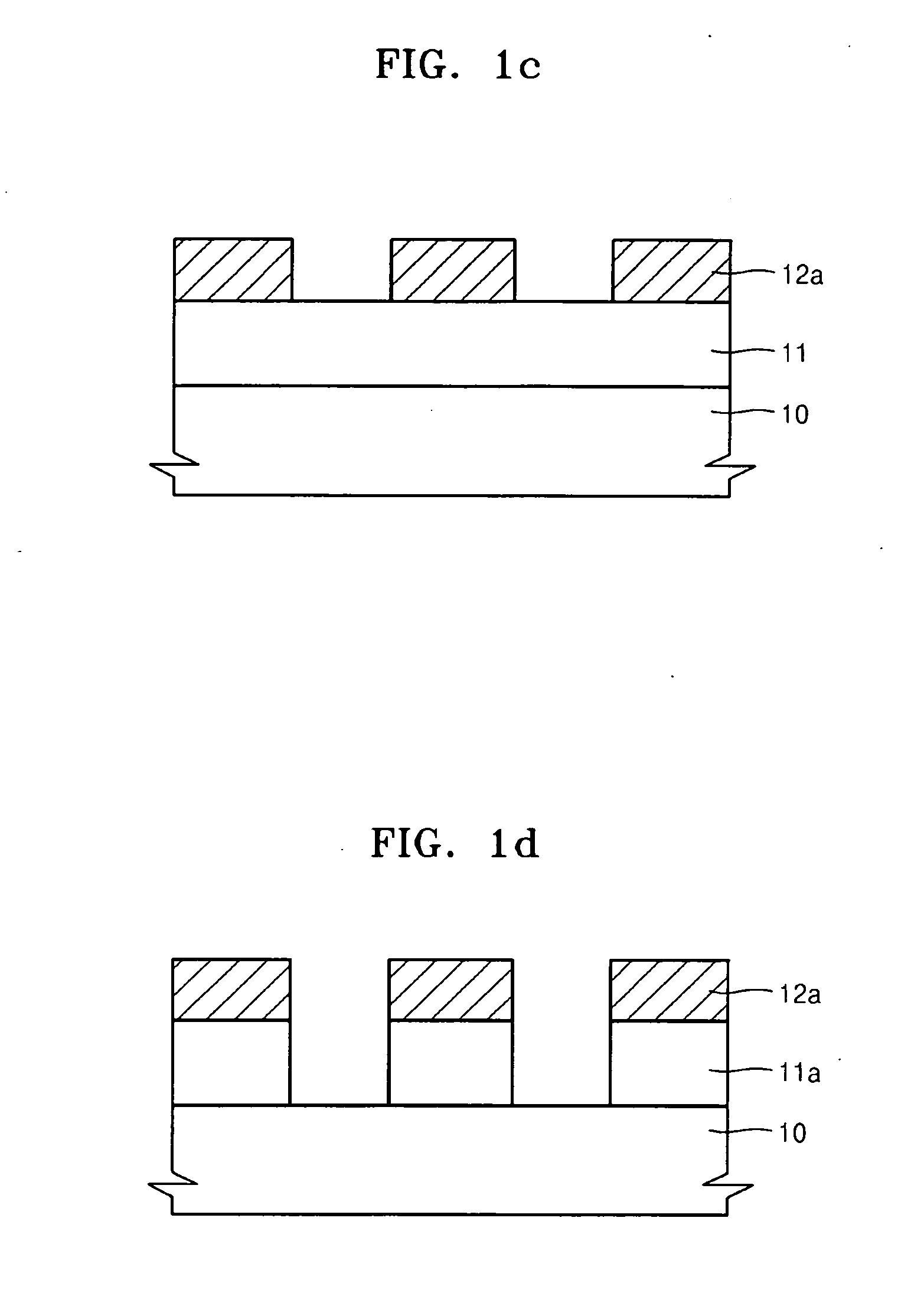

Image

Examples

preparation example 1a

Preparation of Hexagonal Boron Nitride to which Nitro Group (NO2) and —HSO3 Functional Group are Bonded

[0246]A hexagonal boron nitride (h-BN), to which a nitro group (NO2) and —HSO3 functional group were bonded, was obtained in the same manner as in Preparation Example 1, except that 10 ml of a mixture of a nitric acid and a sulfuric acid at a weight ratio of 1:3 was used instead of 10 ml of the 30 wt % H2O2 solution.

preparation example 1b

Preparation of Hexagonal Boron Nitride to which —HSO3 Functional Group is Bonded

[0247]A hexagonal boron nitride (h-BN), to which —HSO3 functional group was bonded, was obtained in the same manner as in Preparation Example 1, except that 10 ml of oleum was used instead of 10 ml of the 30 wt % H2O2 solution.

preparation example 2

Preparation of Hexagonal Boron Nitride to which —NH2 Functional Group is Bonded

[0248]100 mg of h-BN and 10 ml of a hydrazine (N2H4) solution was placed in an autoclave, and a temperature was increased to 100° C., and the mixture was allowed to react for about 12 hours or more. When the reaction was completed, the resultant was filtered, and thus a hexagonal boron nitride (h-BN), to which —NH2 was bonded, was obtained from the N2H4 solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity | aaaaa | aaaaa |

| polydispersity | aaaaa | aaaaa |

| polydispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com