Method for modifying boron nitride nanosheet surface with polydopamine

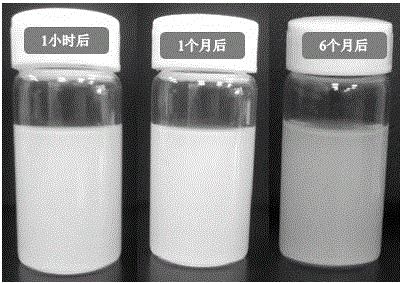

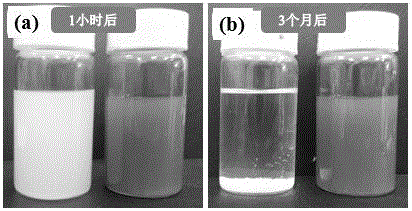

A polydopamine and nanosheet technology, which is applied in the field of new materials, can solve the problems of unfavorable industrial production, storage and application of boron nitride nanosheets, easy agglomeration of boron nitride nanosheets, complicated post-processing process, etc., and achieves difficult agglomeration. Settling, easy operation, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

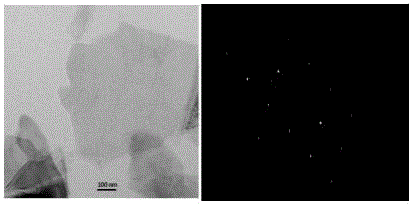

[0033] Example 1: First, take a certain quality of isopropanol and deionized water, so that the mass ratio of isopropanol and deionized water is 3:2, prepare a mixed solvent of polar organic solvent and water; then, take 3 g of hexagonal nitrogen Add the boron powder into the reaction vessel, then add 300 mL of the mixed solvent of isopropanol-deionized water prepared at a mass ratio of 3:2 into the reaction vessel, mix and stir evenly; finally, the reaction system is ultrasonically The stripping temperature was 20-50°C, and the power was 1350 W, and the reaction was performed for 2 hours first; after the ultrasonic stripping was completed, the mixture was centrifuged at a centrifugal speed of 3000 rpm, and the supernatant was collected for pumping and washing (without Washing with water and ethanol for 2 to 3 times), drying, and finally obtaining hexagonal boron nitride nanosheets. The suction filter membrane is an organic membrane with a pore size of 0.22 μm.

Embodiment 2

[0034]Example 2: First, take a certain mass of N,N-dimethylformamide and deionized water so that the mass ratio of N,N-dimethylformamide and deionized water is 3:2, and prepare a polar organic A mixed solvent of solvent and water; then, take 3 g of hexagonal boron nitride powder and add it to the reaction vessel, and then add 300 mL of N,N-dimethylformaldehyde prepared at a mass ratio of 3:2 to the reaction vessel The mixed solvent of amide-deionized water was mixed and stirred evenly; finally, the reaction system was reacted for 2 hours under the conditions of ultrasonic stripping temperature of 20-50°C and power of 1350 W; after the ultrasonic stripping was completed, the mixed solution was centrifuged Centrifuge at a rate of 3000 rpm, collect the supernatant for pumping, washing (2 to 3 times with deionized water, 2 to 3 times with absolute ethanol), and drying to finally obtain hexagonal boron nitride nanosheets. The suction filter membrane is an organic membrane with a po...

Embodiment 3

[0035] Example 3: First prepare 300 mL of 0.01 mol / L Tris-Cl buffer solution (pH=8.5), take 2 g of boron nitride nanosheets prepared according to the method of Example 1 of the present invention, place them in a beaker, and then pour them into the beaker Add 100 mL of absolute ethanol, then add 300 mL of Tris-Cl buffer solution with a concentration of 0.01 mol / L, stir well, then add 600 mg of dopamine hydrochloride and stir well, and finally put the reaction system at a speed of about 400 rpm Under the condition of magnetic stirring, the reaction was carried out at room temperature for 6 hours. The obtained product was suction filtered, washed (3 to 5 times with deionized water, 3 to 5 times with absolute ethanol), and dried to obtain polydopamine-modified boron nitride nanosheets. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com