Preparation method of cubic boron nitride and diamond polycrystal with nanometer structure

A cubic boron nitride and diamond polycrystalline technology, applied in the field of inorganic non-metallic materials, can solve the problems affecting the hardness, wear resistance, thermal stability, large particle size, and difficulty of reaching the edge of the cubic boron nitride-diamond polycrystalline material. Issues such as mouth flatness and sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

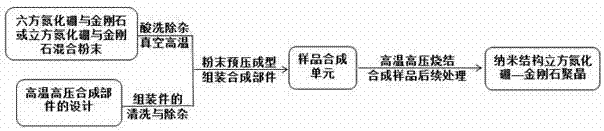

[0027] The mixed powder of diamond with an average particle size of 0-2 μm and hexagonal boron nitride with an average particle size of 0-2 μm is selected, wherein the mass fraction of diamond is 85%, according to figure 1 The process flow chart shown prepares a high-performance nanostructured cubic boron nitride-diamond polycrystalline material. The mixed powder of diamond and hexagonal boron nitride is first put into hydrofluoric acid with a concentration of 20%-40%. The ratio of the amount of hydrofluoric acid to the mixed micropowder is 2 milliliters per carat (ml / ct), heated in a water bath at 70°C, and continuously stirred for 72 hours. After the treatment, when the fine powder settles, pour off the liquid and repeat dilution with deionized water until it is close to neutral. Put the hydrofluoric acid-treated mixed micropowder in hydrochloric acid with a concentration of 20%-38%, the ratio of the acid to the mixed micropowder is 2 milliliters / carat (ml / ct), and heat it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com