Doped hexagonal boron nitride nano sheet, preparation method thereof, catalyst using same as carrier, and applications thereof

A technology of hexagonal boron nitride and nanosheets is applied in physical/chemical process catalysts, chemical instruments and methods, nanotechnology and other directions to achieve the effects of improving catalytic activity, simple post-processing and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing carbon-doped boron nitride nanosheets (CBN):

[0026] Take 0.31g of boric acid, 0.78g of perylenetetracarboxylic anhydride, and 7.2g of urea into a 100mL flask, then add an appropriate amount of distilled water, stir for 0.5h, spin evaporate to remove water, and dry at 65°C overnight. After the obtained solid was ground evenly, it was put into a tube furnace. Under an inert atmosphere, the temperature was programmed to 900 °C and maintained at this temperature for 3 h. After the reaction, cool to room temperature under the protection of an inert gas, take out the product, grind it, and boil it in hot water at 90°C for 0.5-1h. Filter while hot, wash several times with plenty of hot water and 95% ethanol successively. Finally, the filter cake was dried in a vacuum oven and weighed.

Embodiment 2

[0028] A method for preparing phosphorus-doped boron nitride nanosheets (PBN):

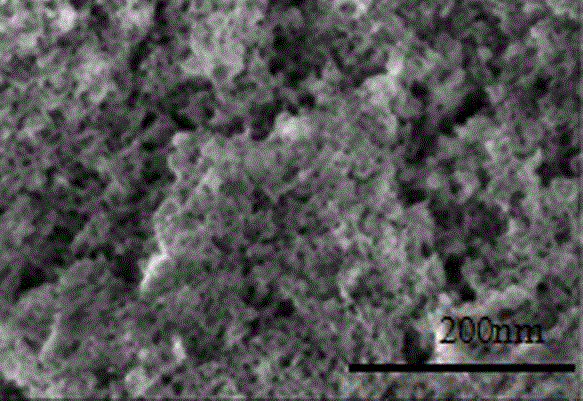

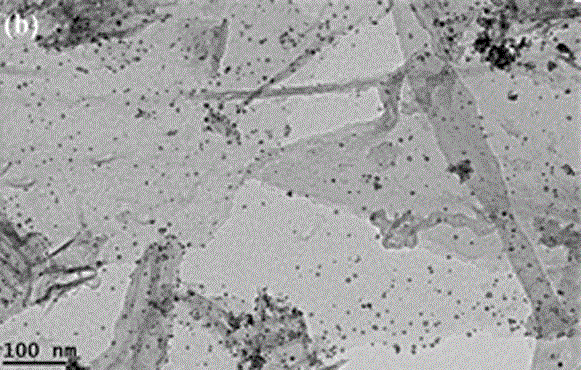

[0029] Take 0.62g of boric acid, 0.31g of red phosphorus, and 7.2g of urea into a 100mL flask, then add an appropriate amount of distilled water, stir for 0.5h, then spin evaporate to remove water, and dry at 65°C overnight. After the obtained solid was ground evenly, it was put into a tube furnace. In an inert atmosphere, the temperature was programmed to 1000 °C and maintained at this temperature for 3 h. After the reaction, cool to room temperature under the protection of an inert gas, take out the product, grind it, and boil it in hot water at 90°C for 0.5-1h. Filter while hot, wash several times with a lot of hot water, toluene and 95% ethanol successively. Finally, the filter cake was dried in a vacuum oven and weighed. The PBN nanosheets were tested by field emission scanning electron microscopy (FESEM). Such as figure 1 As shown, PBN nanosheets have few layers, small thickness, high...

Embodiment 3

[0031] A method for preparing carbon-doped boron nitride nanosheets (CBN):

[0032] Take 0.11g of boron, 0.78g of perylenetetracarboxylic anhydride, and 7.2g of urea into a 100mL flask, then add an appropriate amount of distilled water, stir for 0.5h, then spin evaporate to remove water, and dry at 65°C overnight. After the obtained solid was ground evenly, it was put into a tube furnace. Under an inert atmosphere, the temperature was programmed to 900 °C and maintained at this temperature for 3 h. After the reaction, cool to room temperature under the protection of an inert gas, take out the product, grind it, and boil it in hot water at 90°C for 0.5-1h. Filter while hot, wash several times with plenty of hot water and 95% ethanol successively. Finally, the filter cake was dried in a vacuum oven and weighed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com