Functionalized boron nitride nanosheet and preparation method and application thereof

A functionalized, nanosheet technology, applied in the field of nanomaterials, can solve the problems of low preparation efficiency, high cost, poor dispersibility, etc., and achieve the effects of simple operation, low production cost, and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

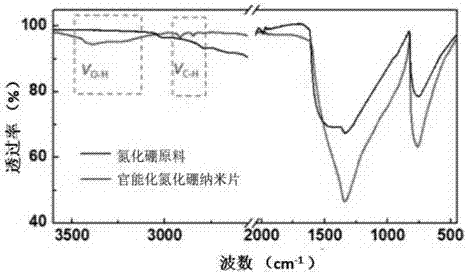

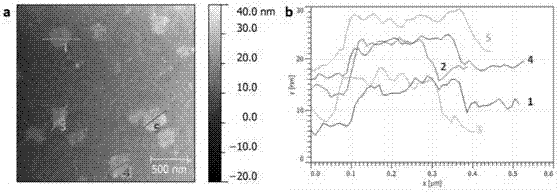

[0035]Mix 10g of sucrose crystals with 1g of boron nitride powder evenly, put them together with 110g of stainless steel balls with a diameter of 6mm into a 250ml stainless steel ball mill jar, seal and mill on a QM-3SP2 planetary ball mill at a speed of 200rpm for 24 hours. After opening the ball mill jar, you can smell the smell of ammonia gas, which indicates that boron nitride and sucrose have undergone a mechanochemical reaction. The mechanism may be that the boron atom combines with the oxygen of the sucrose hydroxyl group, and the nitrogen atom combines with the hydrogen of the hydroxyl group to form ammonia through a multi-step reaction. gas. The ball-milled product was ultrasonically washed with 100 ml of deionized water, and filtered with a microporous membrane. Wherein the obtained filtrate has a pH value of alkaline, which is caused by dissolved ammonia or amine. The resulting filter cake was washed and filtered twice, each time with 100 ml of deionized water. Th...

Embodiment 2

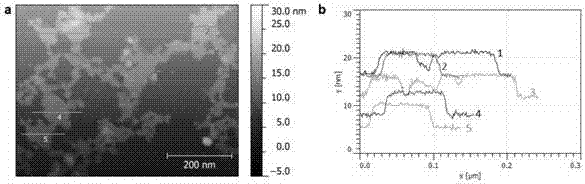

[0038] Mix 10g of sucrose crystals with 1g of boron nitride powder evenly, put them together with 110g of stainless steel balls with a diameter of 6mm into a 250ml stainless steel ball mill jar, seal and mill on a QM-3SP2 planetary ball mill at a speed of 500rpm for 16 hours. Ultrasonic wash with 100ml deionized water and centrifuge at 8000rpm for 10 minutes. The obtained precipitate was repeatedly washed-centrifuged twice, each time with 100 ml of deionized water. Then the precipitate was vacuum-dried at 60°C for 12 hours, and the functionalized boron nitride nanosheet powder was obtained after grinding. Take 0.2 g of powder and ultrasonically disperse in 20 ml of deionized water for 1.5 hours in a water bath, and absorb the supernatant after standing for 12 hours to obtain an aqueous dispersion of functionalized boron nitride nanosheets. attached image 3 The AFM image of the obtained functionalized boron nitride nanosheets shows that the thickness of the functionalized bo...

Embodiment 3

[0040] Mix 10g of sucrose crystals and 1g of boron nitride powder evenly, add them together with 100g of 10mm in diameter stainless steel balls and 30g of 1mm in diameter stainless steel balls into a 250ml stainless steel ball mill jar, seal it and run it on a QM-3SP2 planetary ball mill at 500rpm Speed ball milling for 24 hours.

[0041] Ultrasonic wash with 100ml deionized water, filter with microporous membrane. The obtained filter cake was repeatedly washed-filtered 3 times, each time with 100 ml of deionized water. Then take 5g of wet filter cake (about 10wt% solid content) in 50ml deionized water water bath ultrasonic dispersion for 2 hours, centrifuge at 2000rpm speed for 10 minutes, absorb the supernatant to obtain the aqueous dispersion of functionalized boron nitride nanosheets. Take an appropriate amount of the dispersion liquid, filter it, and vacuum-dry it at 60 degrees for 12 hours, and obtain functionalized boron nitride nanosheet powder after grinding. Calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Plane size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com