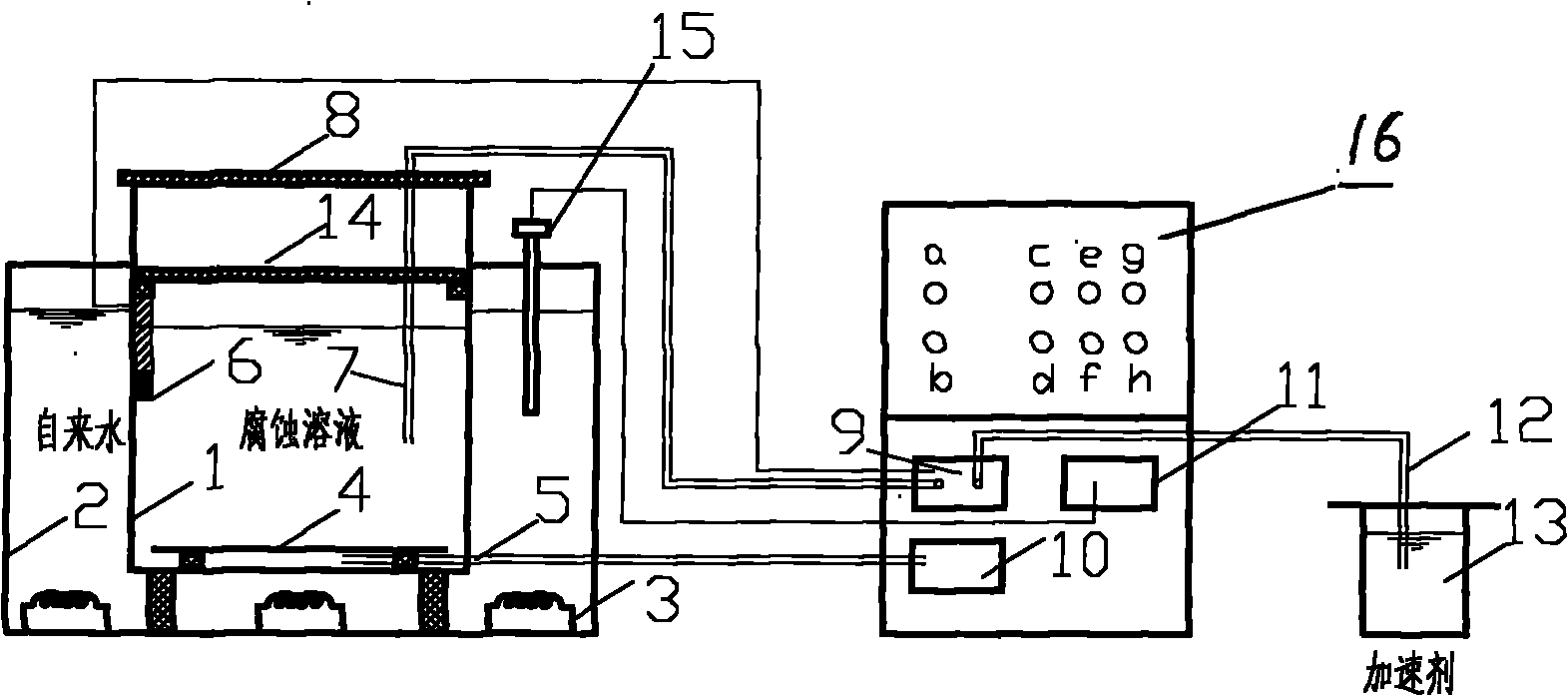

Analog accelerated corrosion test device

An accelerated corrosion test and accelerator technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of large error in test data, inconvenient process operation, complex structure and principle, etc. Low test cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

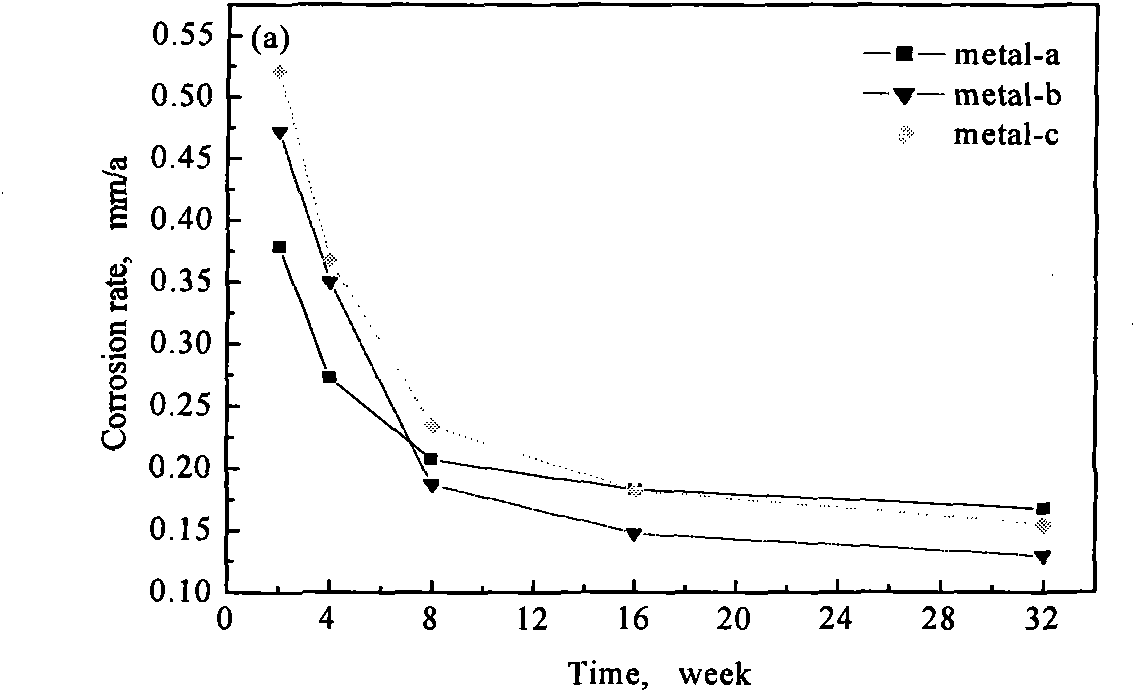

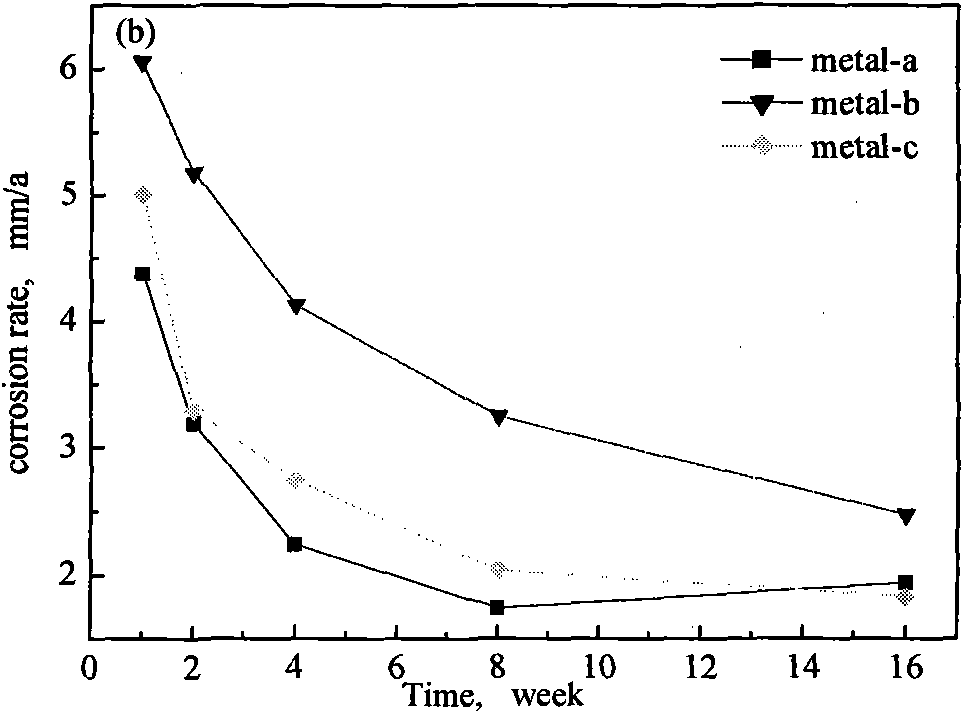

[0013] In this embodiment, the above-mentioned test device is used to carry out indoor simulated accelerated corrosion tests of different metal materials. The simulated accelerated test is carried out in the test box 1, and different samples with a size of 100 × 200 × 3mm are hung on the sample holder 14. Turn on the inflation switch e to carry out inflation and stirring, add tap water into the water bath box 2, and use the temperature control switch h to control the temperature at 35°C, turn on the accelerator switch a, adjust the accelerator speed control knob b, and pass the accelerator concentration probe 6 And accelerator concentration controller 9 controls the concentration of accelerator at 0.05mol / L, after the test starts, monitor the concentration of accelerator through accelerator concentration probe switch c, and feed back to accelerator concentration controller 9 according to its change information to adjust adding Accelerator speed. According to the above steps, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com