Ice formation condition detector

A technology of icing conditions and detectors, which is applied to aircraft parts, deicing devices, transportation and packaging, etc., can solve the problems of destroying the aerodynamic shape, installation can not be fully fitted, etc., to achieve the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

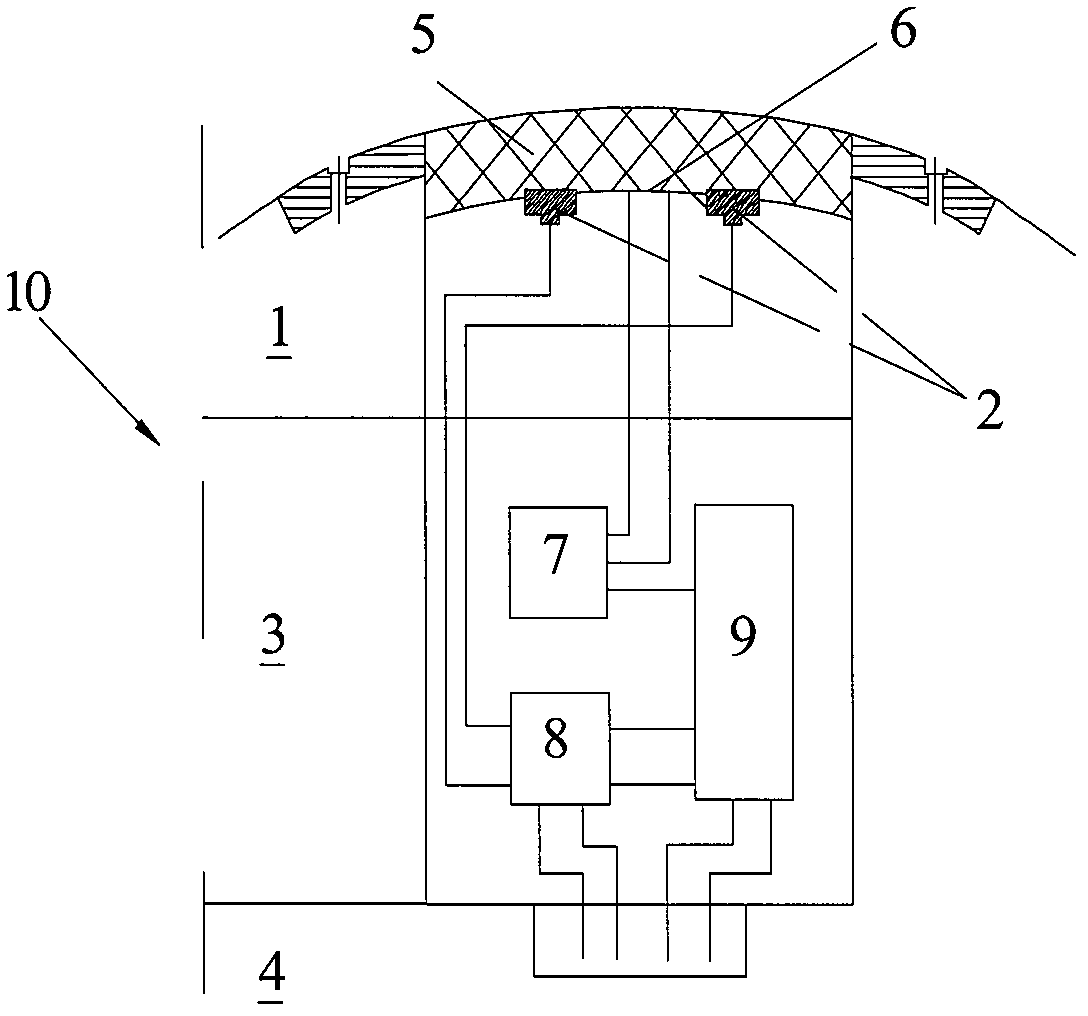

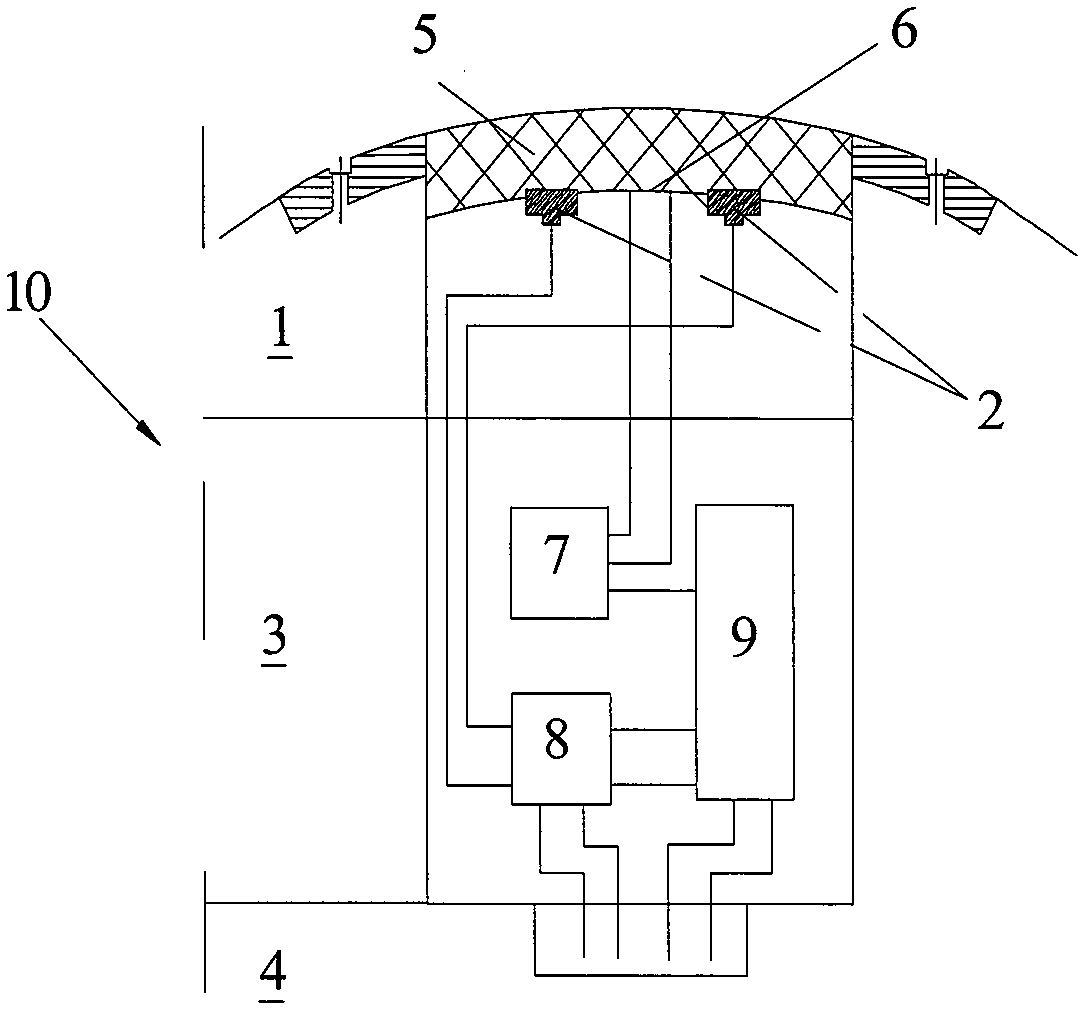

[0030] A preferred embodiment of the icing condition detector of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] Such as figure 1 As shown, it schematically shows an icing condition detector 10 according to the present invention, including an inductive element 1 that can be installed flush on surfaces prone to icing such as wings and engine intakes, for measuring the temperature of the inductive element The temperature sensor 2, the controller 3 and the electrical connector 4.

[0032] The sensing element 1 is composed of a temperature sensing layer 5 and a heat insulating layer 6 . A resistance wire (not shown) is embedded in the temperature sensing layer 5 for heating the temperature sensing layer 5 . The heat insulating layer 6 is fixed, for example, bonded on the inner surface of the temperature sensing layer 5 by an adhesive, so as to prevent the heat of the temperature sensing layer 5 from dissipating throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com