Aircraft surface humidity online monitoring sensing probe

A technology for sensing probes and aircraft surfaces, applied in the direction of material impedance, etc., can solve the problems of deterioration of corrosion conditions, reduction of equipment and facility service cycles, waste of manpower and material resources, and time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

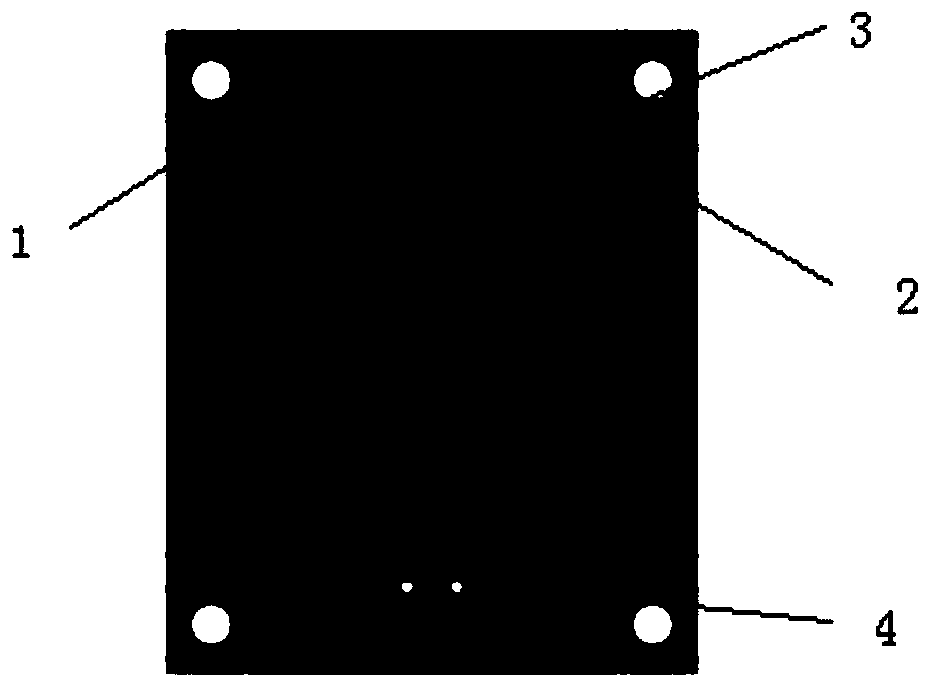

[0033] Aircraft surface humidity online monitoring sensor probe mainly includes printed circuit board (PCB board), copper electrode and interface.

[0034] PCB board: size (5.0*4.0) cm, single layer, with fixing bolt holes, weighing about 10g;

[0035] Copper electrode: interdigitated electrode, "finger" length 35mm, "finger" width 1mm, distance between "finger" and "finger" 1mm, 8 fingers on one side.

[0036] Interface: The diameter of the hole is 1.5mm, which is used to connect the signal collector and the surface humidity probe.

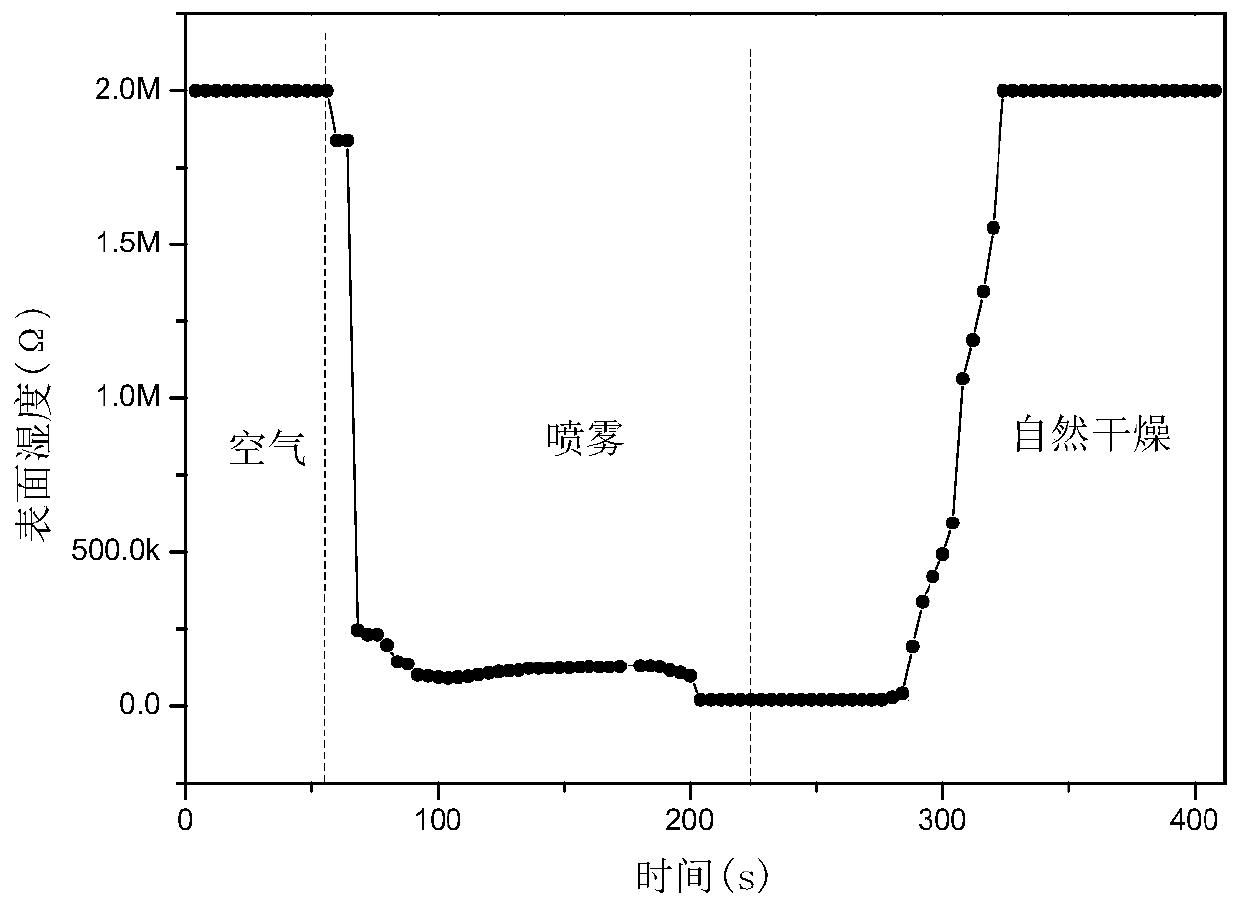

[0037] The following is the experimental verification carried out according to the above probe design: the surface humidity probe is placed in the air, sprayed with water mist and dried naturally, and the reliability of the surface humidity probe is tested and evaluated. figure 2 It is a verification example for the online monitoring probe of surface humidity. The initial state of the surface humidity probe is placed in the air without water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com