Anti-icing wind power generation blade

A technology for wind power generation blades and anti-icing, which is applied in wind power generation, wind turbines, engines, etc. It can solve the problems of high power consumption, difficult installation and maintenance, and the inability of anti-icing coatings to actively deicing, and achieve high heat generation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

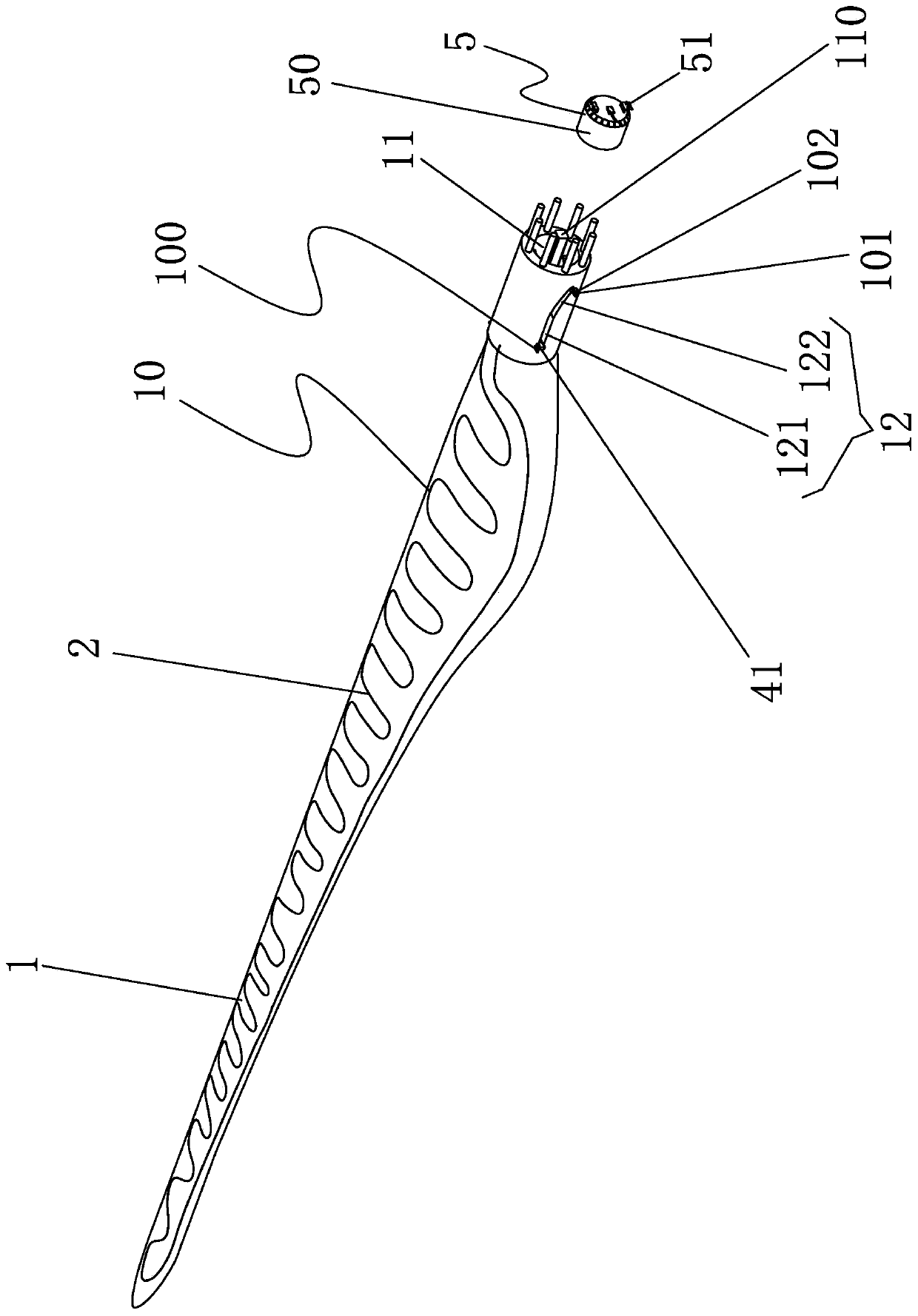

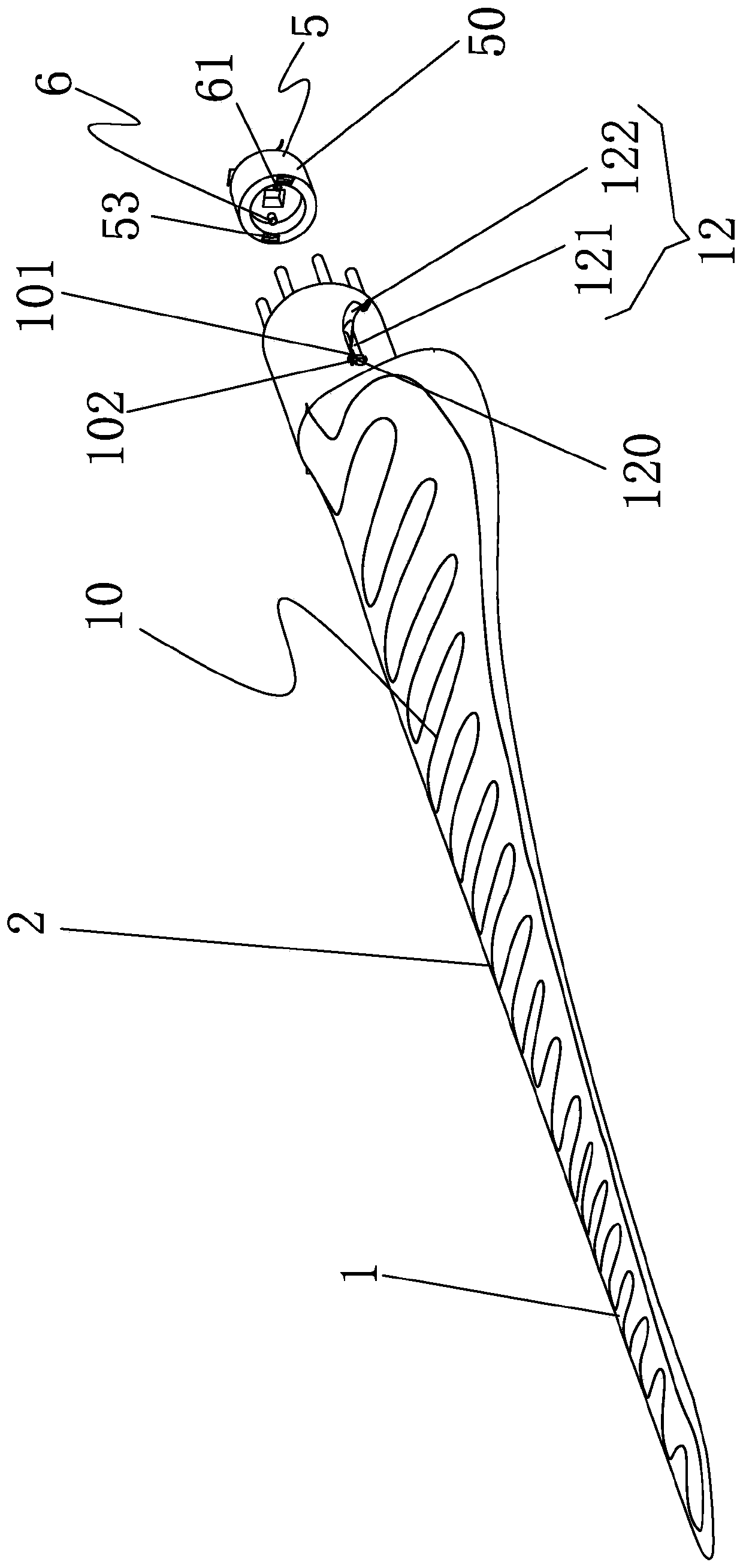

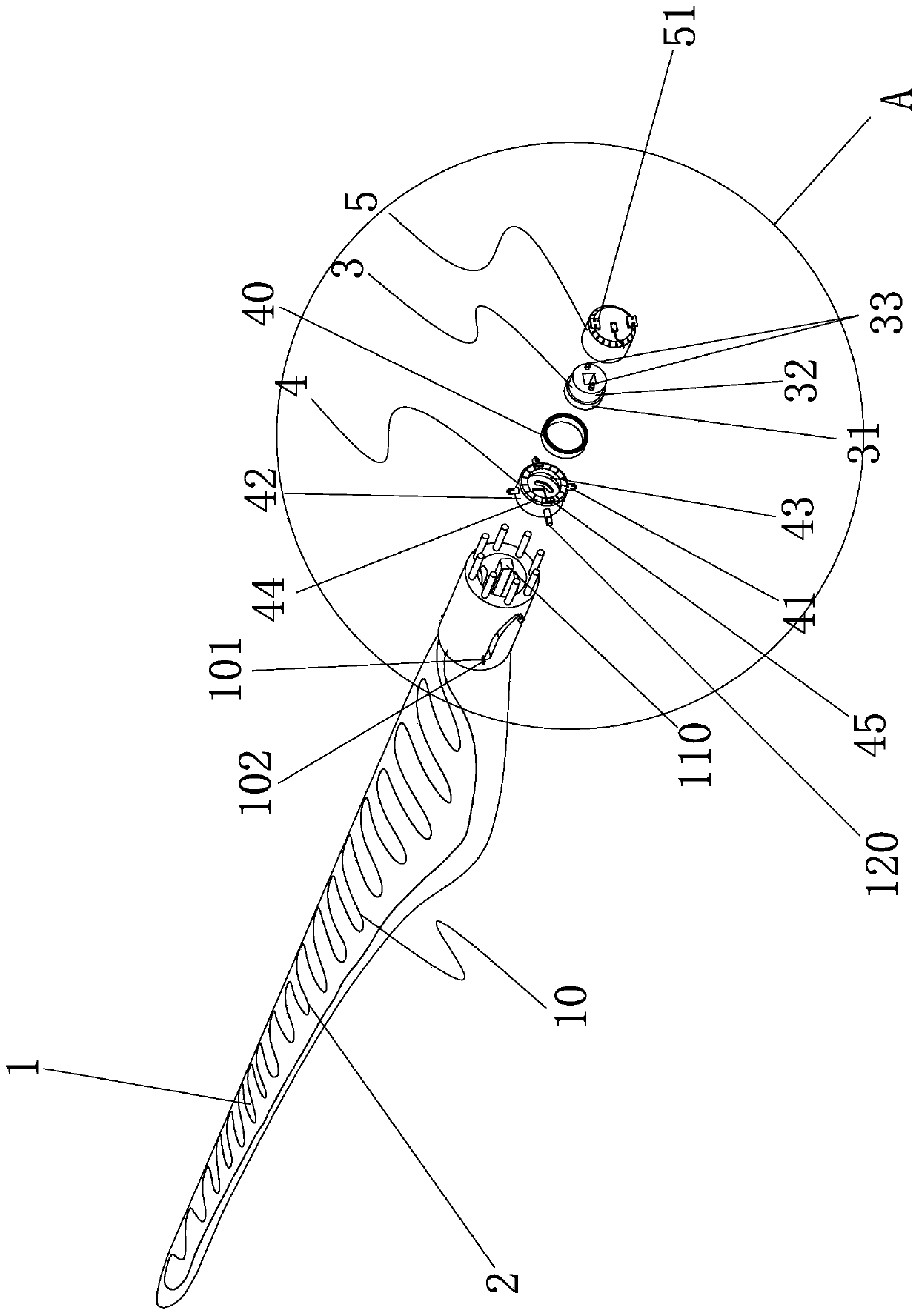

[0033] like Figures 1 to 9 A kind of anti-icing wind power generation blade shown, comprises blade body 1, is provided with the deicing device 10 that can prevent wind power generation blade from icing on described blade body 1, and described deicing device 10 is carbon nanotube heating Wire 2, the carbon nanotube heating wire uses a non-metal-doped carbon nanotube electrocatalytic material, which has the advantages of high heating rate, energy saving and environmental protection, and is not limited by any external dimensions, and does not require miscellaneous wiring. The electrothermal conversion rate reaches more than 95%, which is unmatched by the current traditional resistance heating mode. After the carbon nanotube heating wire 2 is installed and arranged, the carbon nanotube heating wire 2 is covered and reinforced with a wear-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com