Neighbor discharging and dissipating aircraft skin heat dissipation system based on wind-liquid comprehensive heat dissipation structure

A technology of aircraft skin and heat dissipation structure, which is applied in the direction of aircraft parts, fuselage, fuselage bulkhead, etc., can solve the unfavorable operation, maintenance and repair of aircraft skin radiators, and the lack of wide application of aircraft skin radiators. The problem of long transportation distance of cooling capacity has achieved the effect of easy maintenance and maintenance, stable heat dissipation capacity and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

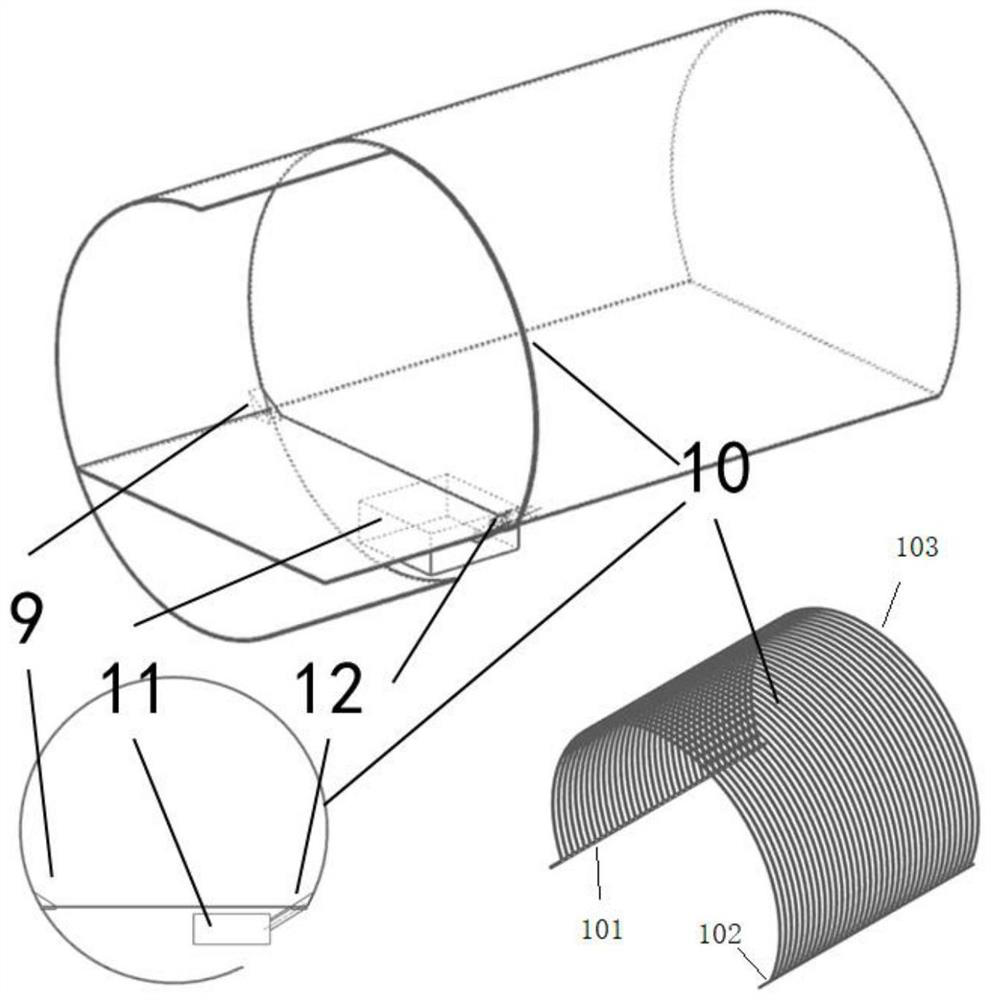

[0024] combine Figure 1-Figure 7 , a kind of air-liquid integrated heat dissipation structure based on the present embodiment of the nearby exhaust aircraft skin radiator, including airborne equipment liquid cooling pipeline 1, air-liquid integrated heat dissipation conversion pipeline 2, cabin air cooling regeneration circuit 3.

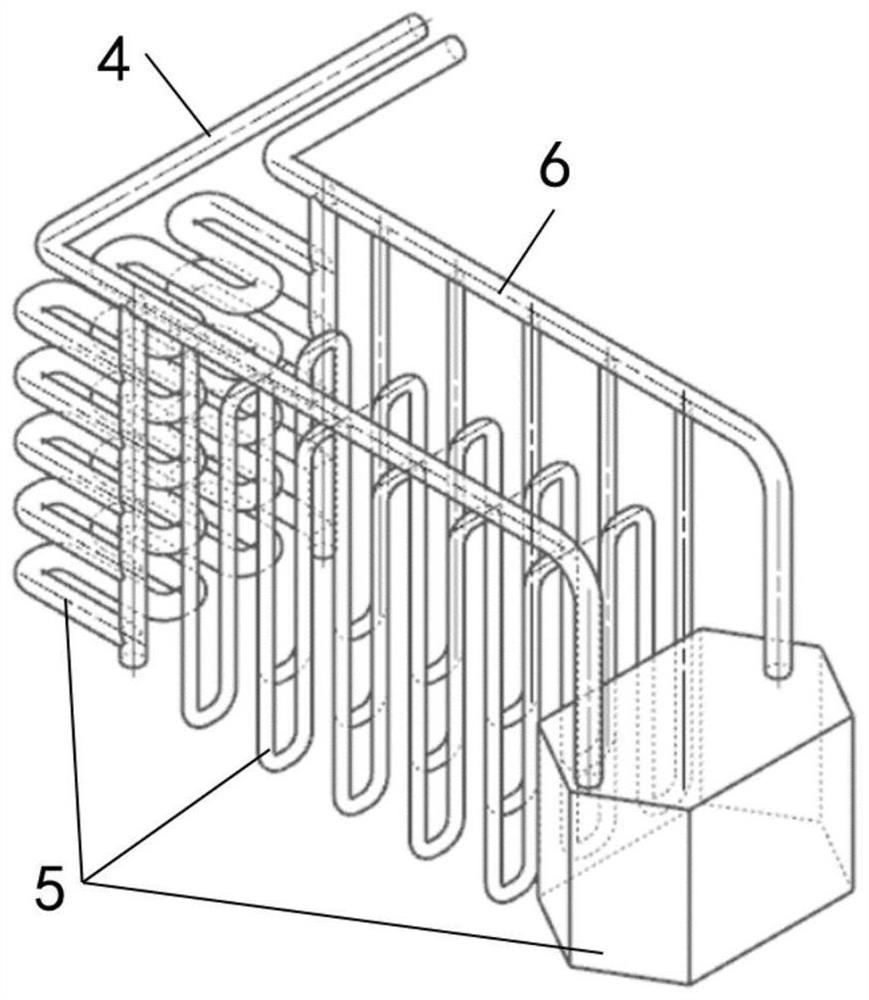

[0025] The airborne equipment liquid cooling pipeline 1 includes a liquid supply pipeline 4, each airborne equipment sub-pipeline 5 and a liquid discharge pipeline 6, and the liquid cooling working medium is input into each airborne equipment subpipeline 5 in parallel from the liquid supply pipeline 4, After absorbing heat, they are collected and output to the drain line 6.

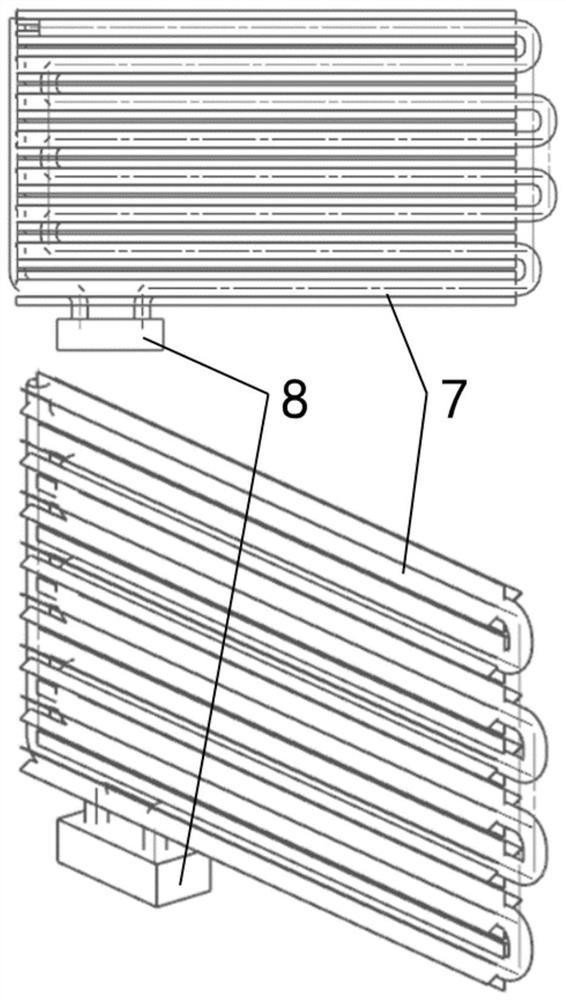

[0026] The air-liquid integrated heat dissipation conversion pipeline 2 includes a heat exchange tube 7 with a fin structure and a fluid cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com