On-line repair technology for smooth shaft abrasion

A smooth and advanced technology, which is applied in the field of online repair of smooth shaft wear, can solve the problems of agitator phosgene leakage, high disassembly and assembly costs, and inconvenient disassembly, so as to save disassembly and assembly costs and time, small heat-affected zone, and easy to use Convenient and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

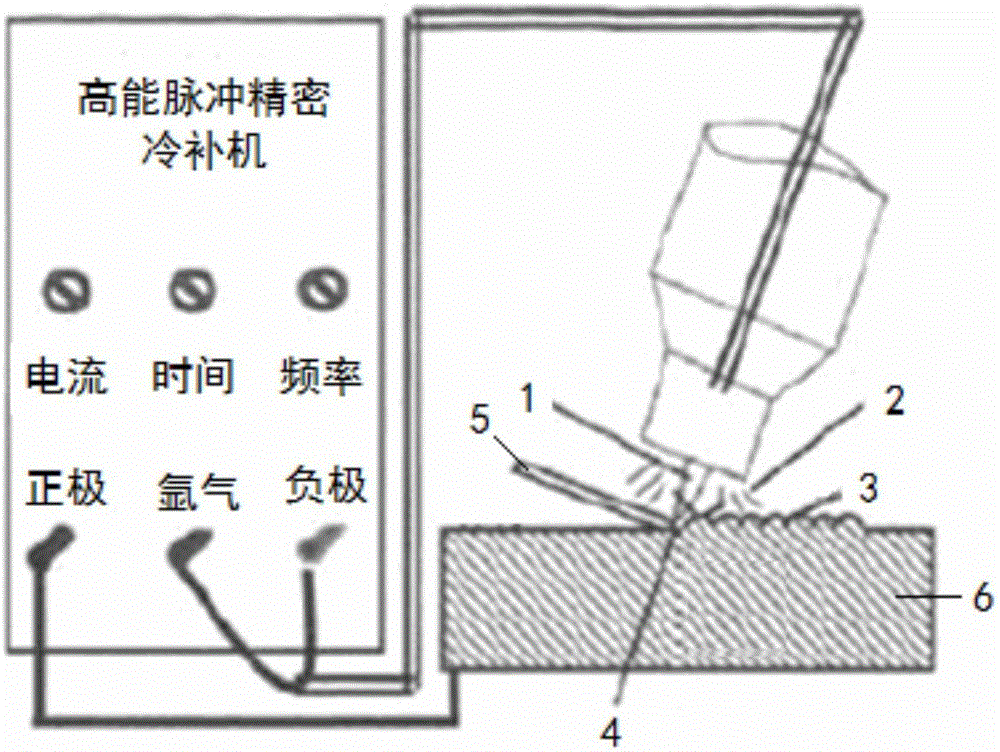

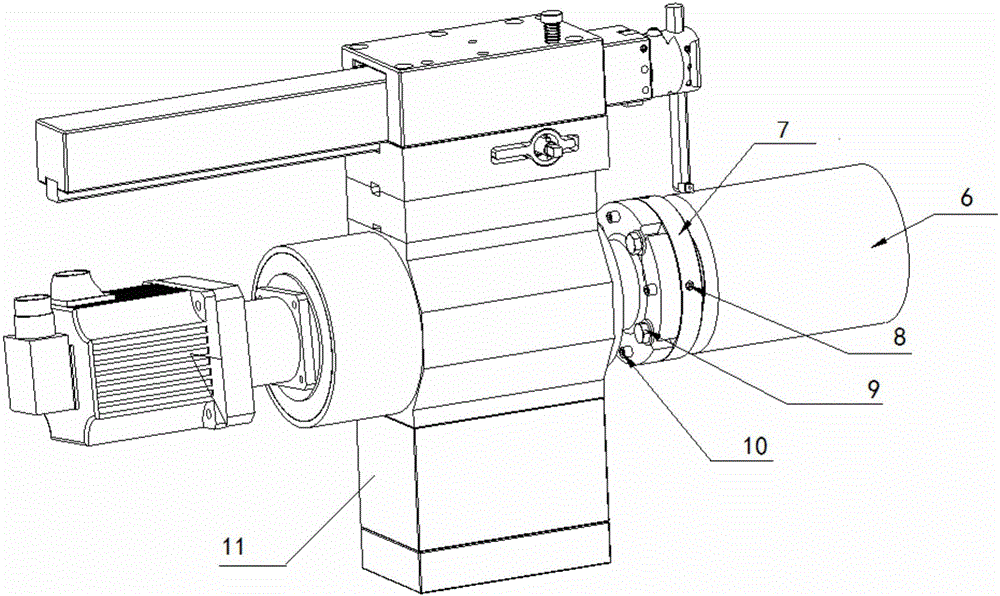

[0039] In the specific implementation process, the online repair process for smooth shaft wear of the present invention adopts a high-energy pulse precision cold repair machine, welds through high-energy pulse cold welding, and the repair process for subsequent processing of the shaft end lathe is mainly composed of the following processes;

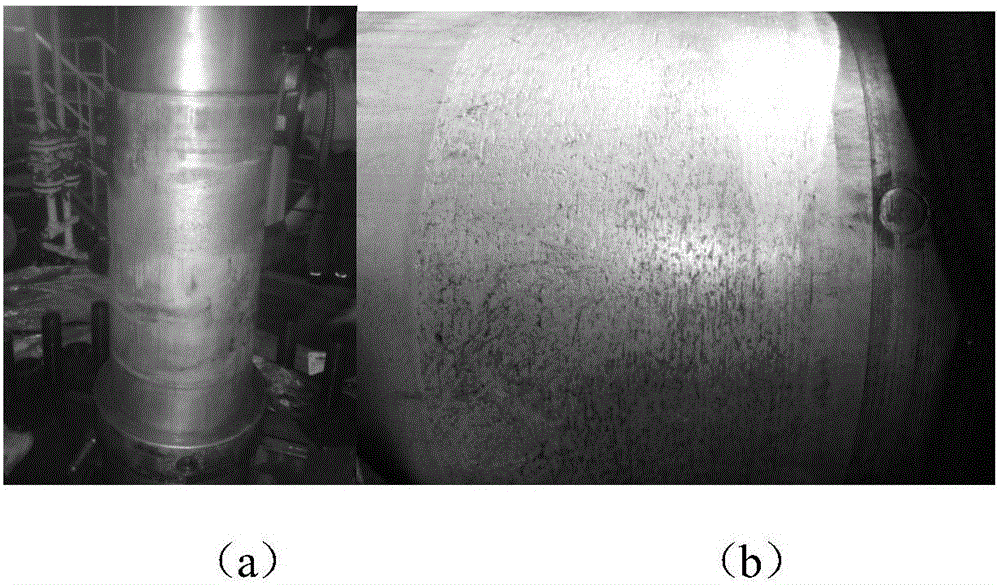

[0040] S1. Determine the repair plan according to the wear degree of the smooth journal working surface and the outer sealing ring of the mixer during the working process;

[0041] In this step, it is necessary to check and confirm the surface cleaning, wear amount, surface defects, dimensional accuracy of the shaft, and runout, and finally determine the repair plan.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com