Chain driving strap

A technology of chain transmission and transmission discs, which is applied to transmission parts, belts/chains/gears, chain rings, etc. It can solve the problems of high cost of use, chain annealing, chain wear, etc., to increase service life, improve lubrication, The effect of guaranteeing supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

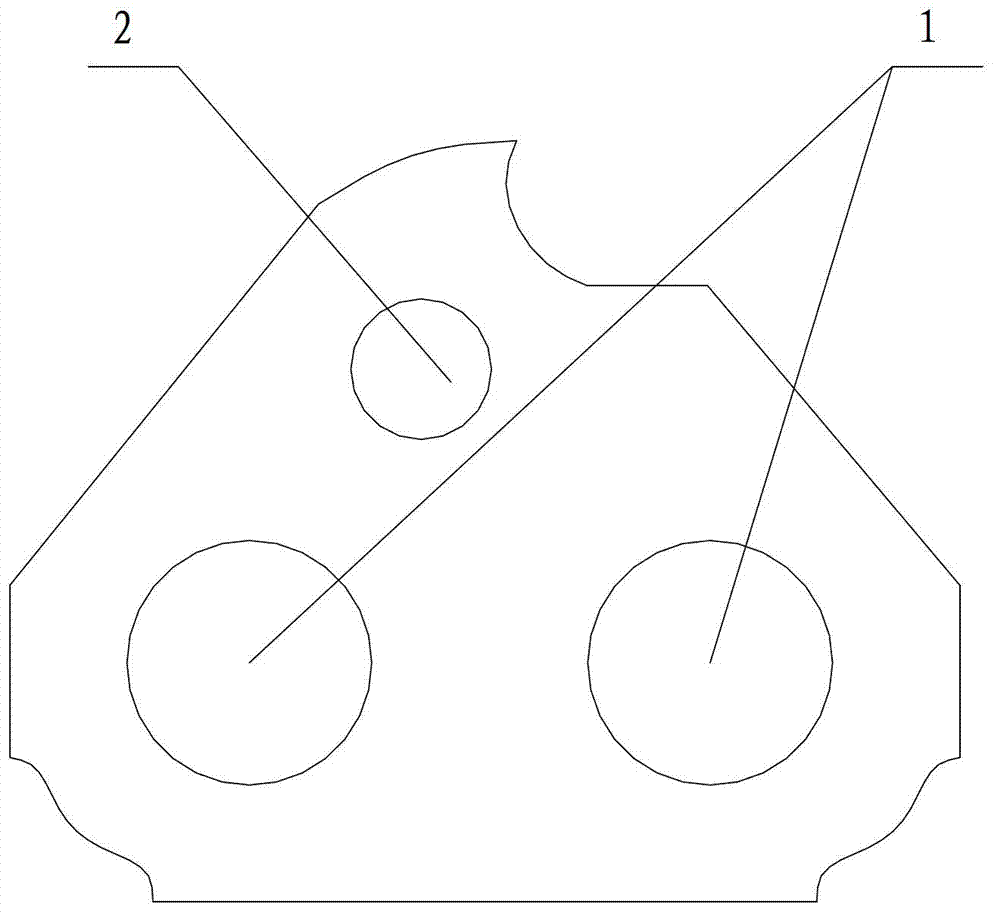

[0017] A chain drive piece, on which two through holes 1 are opened, and the two through holes 1 are used to cooperate with the small holes opened on the blade, and the through holes 1 are riveted with the small holes on the blade by using rivets, so that the blade It is connected end to end with the transmission sheet to form a chain, and several cooling holes 2 are opened on the transmission sheet, and all the cooling holes 2 are equal in size and evenly distributed.

[0018] The existence of heat dissipation holes 2 can assist heat dissipation. During the use of embodiment 1, the temperature rises from normal temperature to 1

[0019] It takes 350 seconds at 50°C, and then rises slowly, up to 280°C, so that the chain will not be annealed, the hardness will not decrease, and the service life of the chain can be increased; secondly, its average service life reaches more than 115 hours, and the transmission of more than 115 hours The degree of wear of the sheet can still ensur...

Embodiment 2

[0021] A chain drive piece, on which two through holes 1 are opened, and the two through holes 1 are used to cooperate with the small holes opened on the blade, and the through holes 1 are riveted with the small holes on the blade by using rivets, so that the blade It is connected end to end with the transmission piece to form a chain, and a cooling hole 2 is opened on the transmission piece, and the cooling hole 2 is opened in the middle of the transmission piece 1 .

[0022] The existence of heat dissipation holes 2 can assist in heat dissipation. During the use of Example 2, it takes 350 seconds for the temperature to rise from normal temperature to 150°C, and then slowly rise to a maximum of 280°C, so that the chain will not be annealed and the hardness will not decrease. It can increase the service life of the chain; secondly, its average service life reaches more than 115 hours, and the wear degree of the transmission plate exceeding 115 hours can still ensure that the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com