Full-automatic vacuum material cleaning machine

A material cleaning machine, fully automatic technology, applied in the field of fully automatic vacuum material cleaning machine, can solve the problems of hidden safety hazards, pungent smell, injury and other problems of operators, achieve the effect of reducing work intensity, reducing machine temperature and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

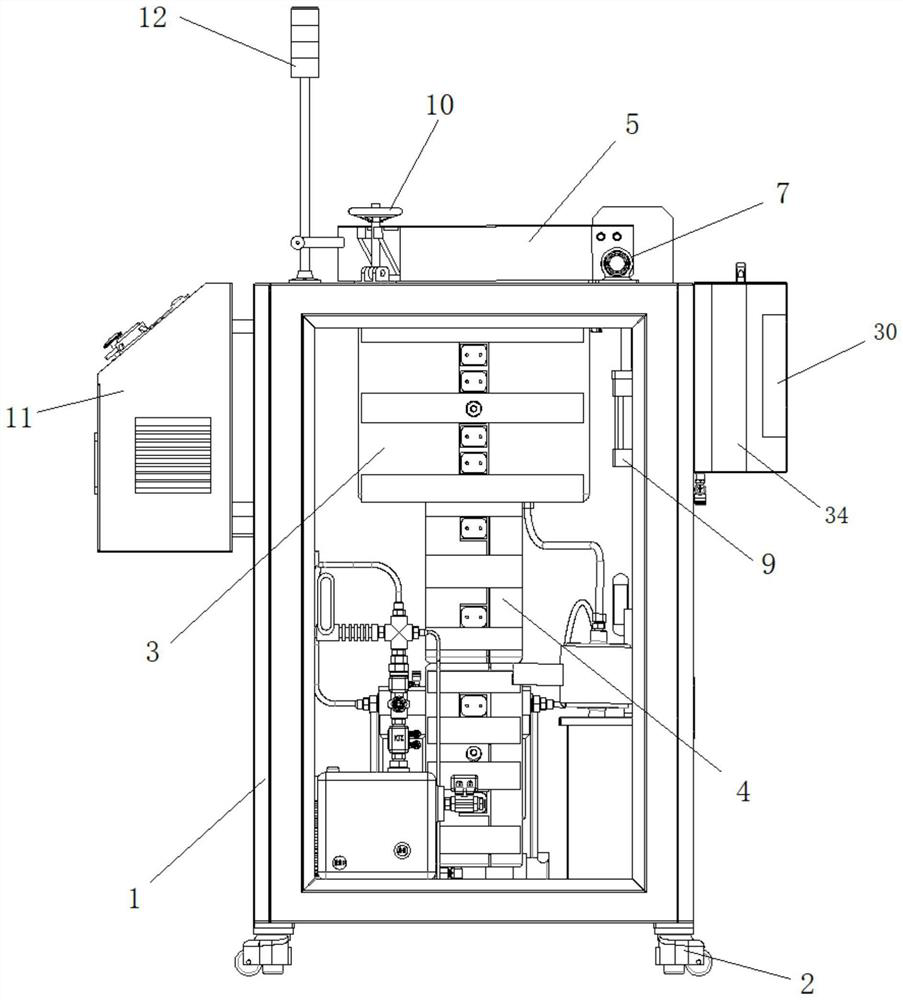

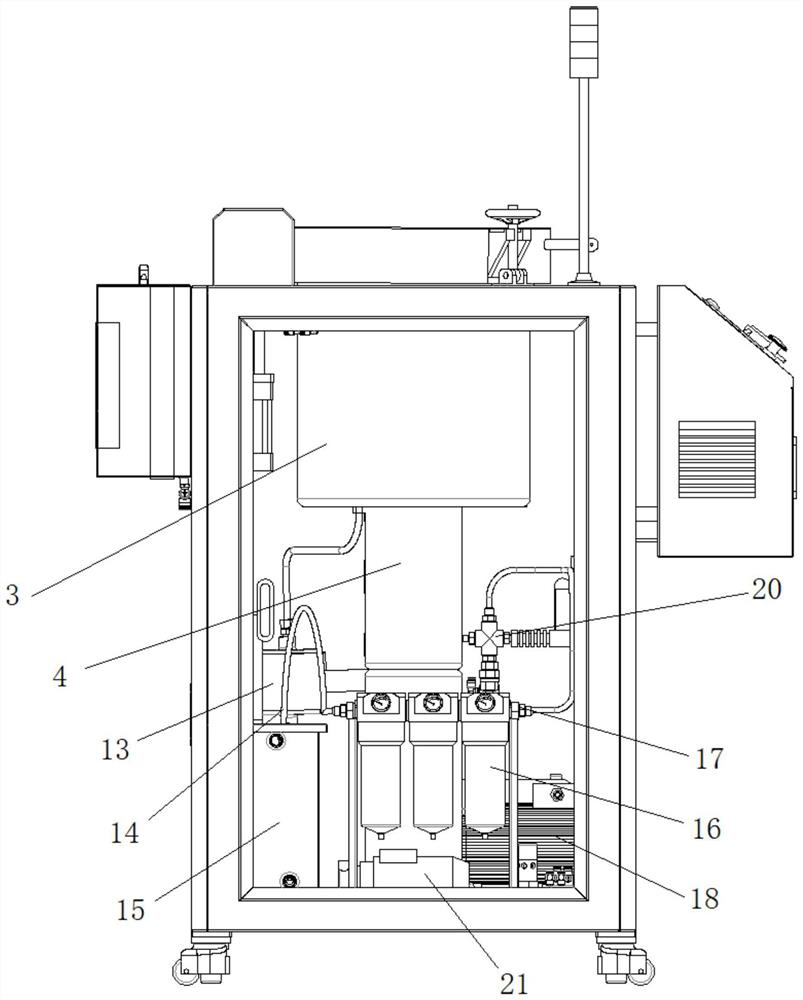

[0057] A fully automatic vacuum cleaning machine, its structure is as follows Figures 1 to 4 As shown, including rack 1, furnace, heating unit 23, cooling unit, exhaust unit, exhaust gas filter unit, cooling water unit, etc., all equipment are all installed in rack 1, and rollers 2 are installed at the bottom of rack 1 , so that the entire cleaning machine can be moved. The specific structure is as follows:

[0058] The hearth is a vertical structure, including the upper hearth 3 and the lower hearth 4, the upper hearth 3 and the lower hearth 4 are both hollow cylindrical structures, the diameter of the upper hearth 3 is greater than the diameter of the lower hearth 4, the two are communicated, and in the lower hearth 4. A suspension rod 31 is provided at the top. The size of the furnace in this embodiment is not limited. Based on the size of the parts to be processed, the larger the parts, the larger the upper furnace 3 and the lower furnace 4 and the corresponding pipes a...

Embodiment 2

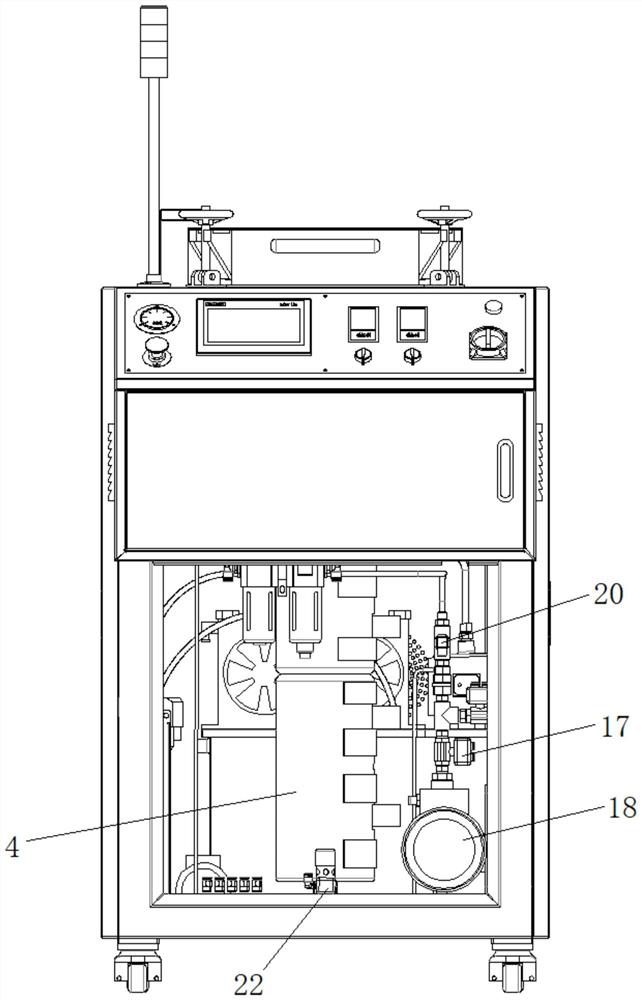

[0069] A fully automatic vacuum cleaning machine, its furnace structure is as follows Figure 8 , Figure 9 As shown, the furnace has a horizontal structure, that is, the horizontal furnace 33, which is mainly for cleaning relatively large linear parts. The horizontal furnace 33 is in the shape of a cube, and large linear parts, such as extruder screws, can be placed inside it. On one side of the top of the horizontal furnace 33, a furnace cover 5 is installed through a rotating shaft 6, and one end of the rotating shaft 6 is provided with a rotating gear 7. The cleaning machine is provided with a lifting cylinder 9, and the lifting cylinder 9 is fixed with a rack 8. The rack 8 meshes with the gear 7 . Two furnace cover pressing handles 10 are provided on the other side of the furnace cover 5 . The furnace cover 5 is provided with an asbestos layer 32 for heat insulation, and a cooling water pipeline 25 is provided, which is the same as the first embodiment. A heating unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com