Field repair and remanufacturing process of pressure container

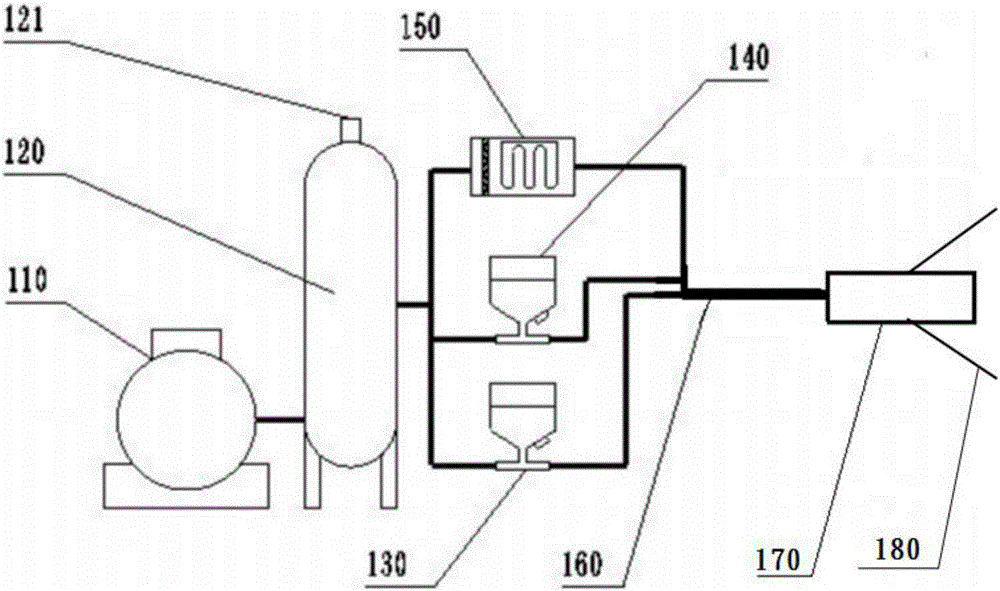

A pressure vessel and remanufacturing technology, applied in metal material coating process, heating inorganic powder coating, coating, etc., can solve the problems of difficult on-site repair, material damage, large tonnage, etc., and achieve easy cold welding repair, extension The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

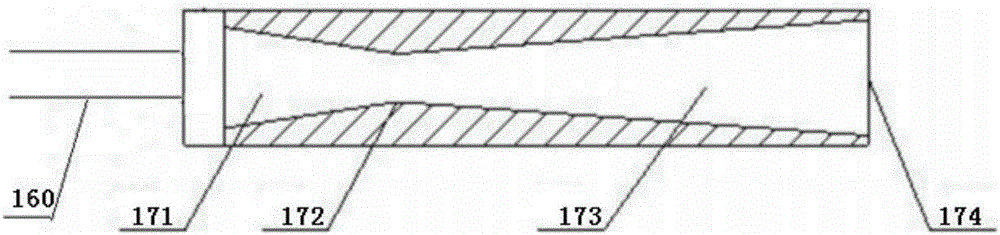

Method used

Image

Examples

Embodiment 1

[0031] Quench Tower Repair

[0032] Introduction: The main function is to rapidly cool the high-temperature tail gas from hydrogenation reduction. It was put into operation in April 2010. The equipment is about 28m high. The cylinder is made of composite plates rolled and welded, and the spherical heads at both ends are made by cold stamping. The parameters are shown in Table 1:

[0033] Table 1 Materials and parameters of quench tower equipment

[0034] name material diameter Thickness (mm) length / height(m) Cylinder 20R+304L Φ3600±18 16±3 20.7 Head 20R+304L Φ3600±18 16±3 0.9 Skirt Q235-B Φ3614 22 6

[0035] Major corrosion features found in 2014:

[0036] (1) Pitting corrosion pits, through corrosion pits, diffusion corrosion pits, mechanical scratches.

[0037] (2) Causes of corrosion: pitting corrosion and uniform corrosion, the cause of pitting corrosion is due to the high chloride ions in the container; the cause o...

Embodiment 2

[0066] The main function of the torch liquid separation tank is to separate the liquid droplets in the exhaust gas. It was put into operation in April 2010. The equipment specifications are: The total weight is 5.2 tons, the cylinder material is SA516GR.70N, and the working medium is H 2 S acidic liquid.

[0067] During the maintenance in 2014, it was found that there were large areas of corrosion pits with different depths at the bottom of the torch liquid separation tank, among which the deepest corrosion point was 6.0mm, and the total corrosion area was about 0.6m 2 .

[0068] Treat with the on-site repair and remanufacturing process of the present invention, the steps are as follows:

[0069] Step 1. Pre-treatment for cold welding

[0070] Use mechanical grinding methods (such as angle grinder, grinder, gauze grinder, small polishing machine, fine whetstone, fine file or fine sandpaper) to remove the rust layer, fatigue layer and oxide layer on the part to be repaired ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com