Polyolefin pipe electrofusion welding joint cold welding defect supersonic detection method

A technology of ultrasonic testing and electrofusion welding, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of joint detection, reliability cannot be guaranteed, joint cold welding cannot be detected, etc. It achieves high detection accuracy, Simple and convenient detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

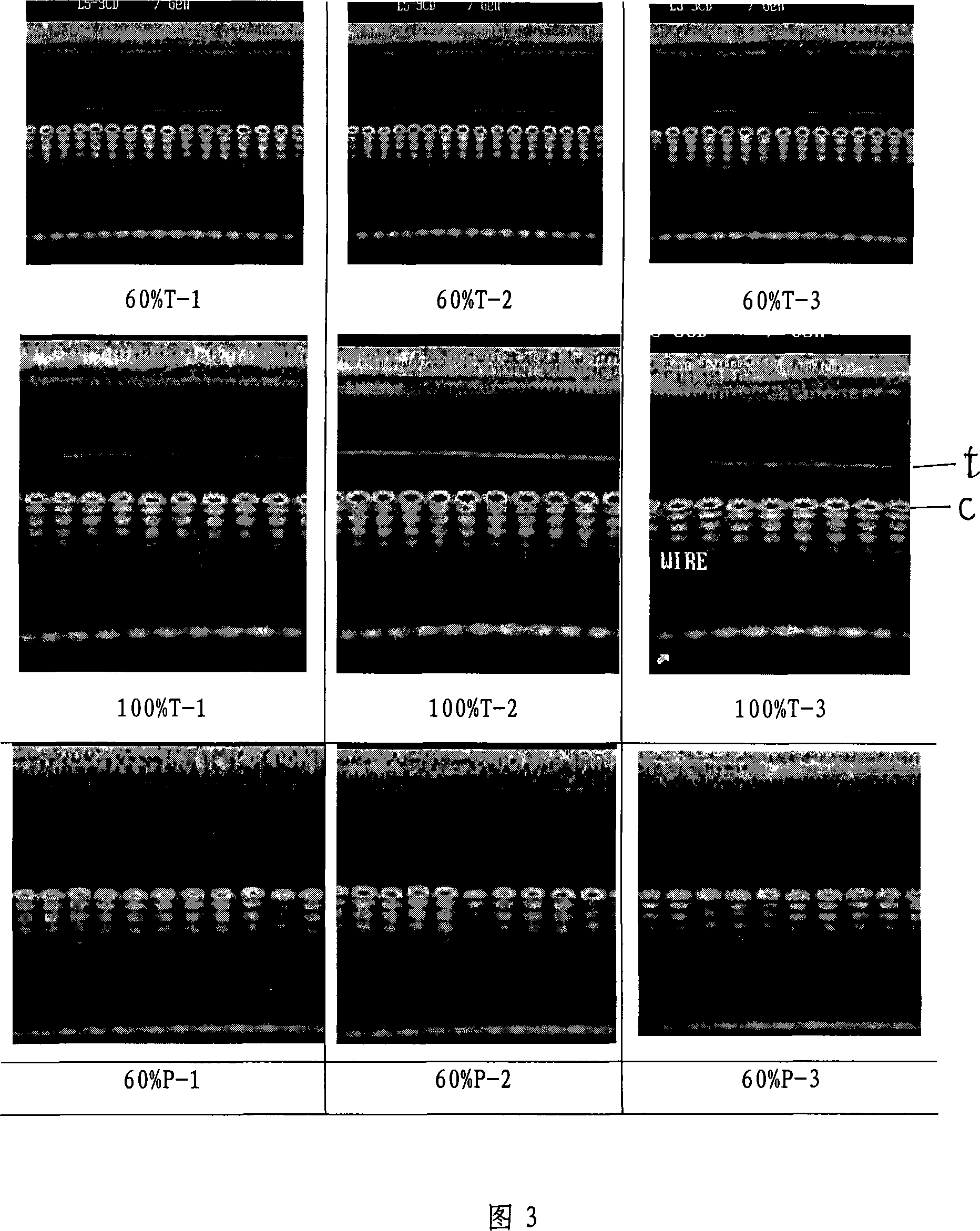

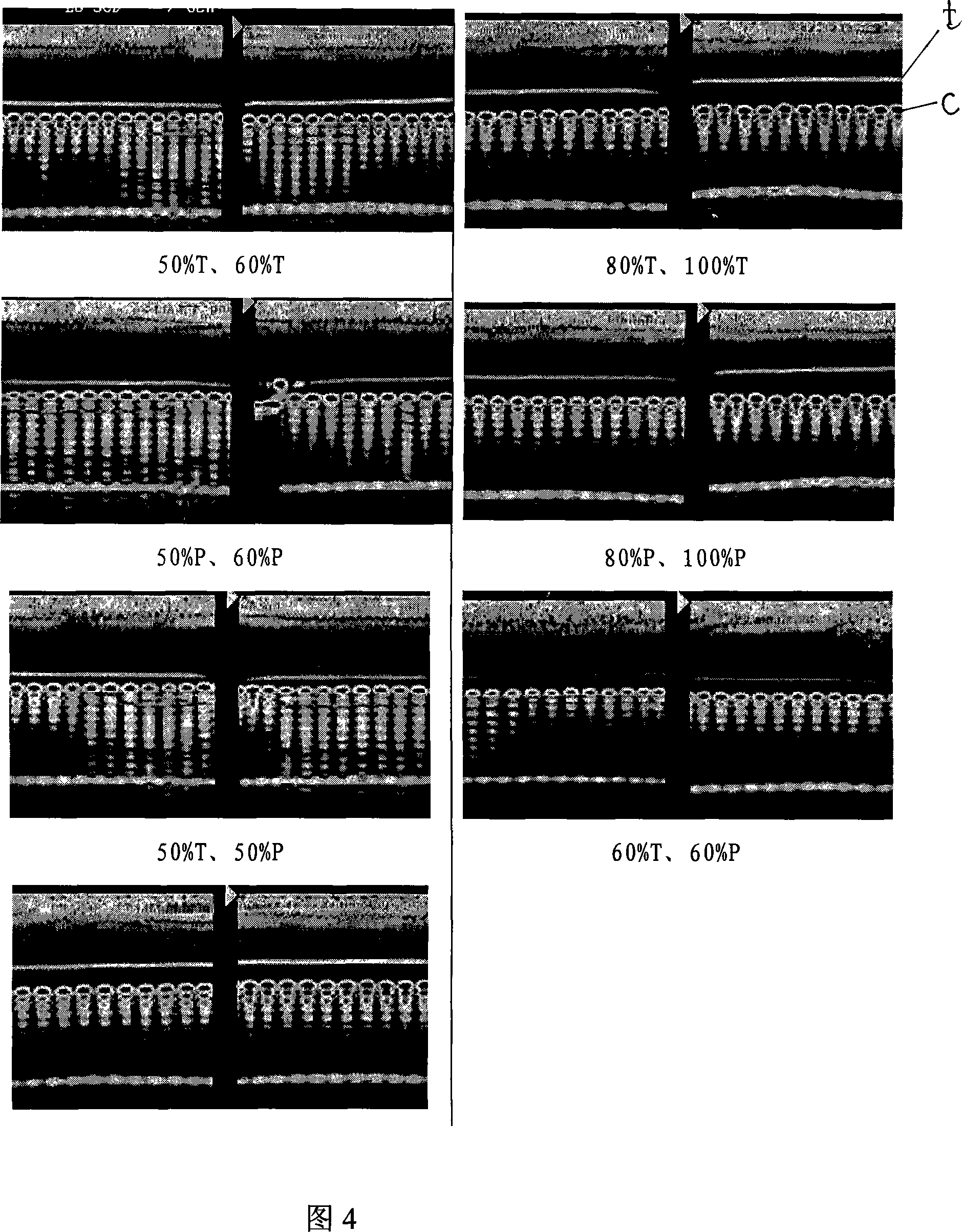

[0039] Example 1: Taking the PE80 material DN90 electrofusion joint as an example, the distance between the characteristic line and the metal wire of the normal welded electrofusion joint measured by ultrasonic testing method is 3.2mm; The distance between the characteristic line and the metal wire is 2.6mm; it can be seen that H=2.6 / 3.2=81.3%, which can be judged as qualified.

Embodiment 2

[0040] Example 2: Taking the PE80 material DN110 electrofusion joint as an example, the distance between the characteristic line and the metal wire of a normal welded electrofusion joint measured by ultrasonic testing method is 3.7mm; The distance between the characteristic line and the metal wire is 2.2mm; it can be seen that H=2.2 / 3.7=56.8%, which can be judged as unqualified.

Embodiment 3

[0041] Example 3: Taking the PE80 material DN63 electrofusion joint as an example, the distance between the characteristic line and the metal wire of a normal welded electrofusion joint measured by ultrasonic testing method is 2.4 mm; The distance between the characteristic line and the metal wire is 2.0mm; it can be seen that H=2.0 / 2.4=83.3%, which can be judged as qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com