Electrofusion welding process for preventing generation of cold welding and over welding defects and electrofusion welder

A technology of electric fusion welding and welding circuit, which is applied in the field of electric fusion welding machine, can solve the problems of different welding time and different welding input power, and achieve the effect of avoiding over welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

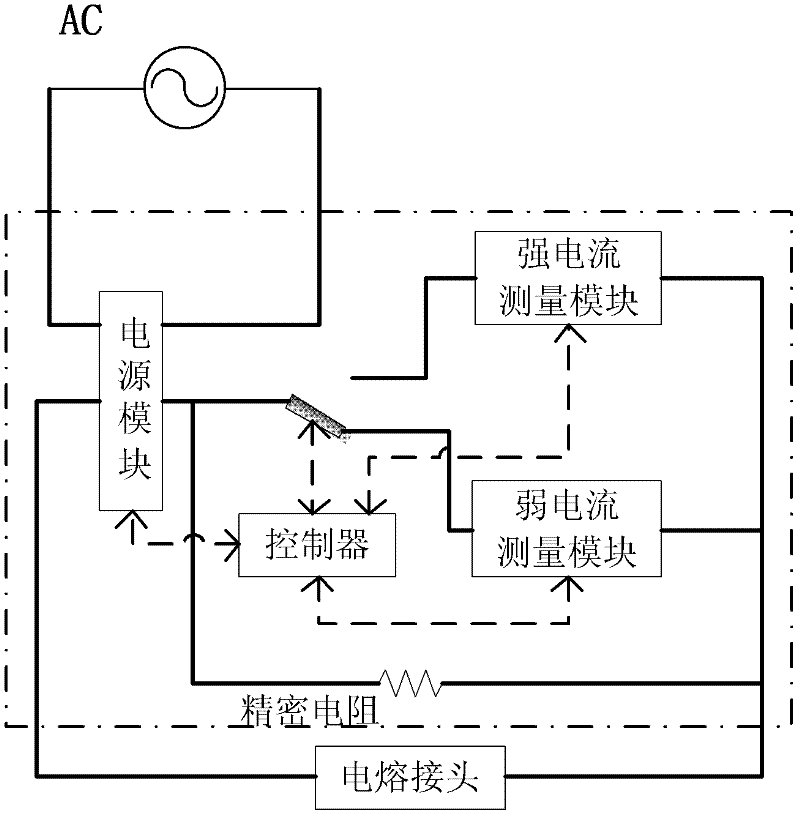

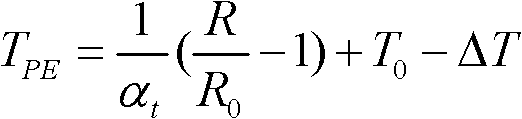

[0041] (1) Obtain the input parameters of electrofusion joint welding

[0042] After the power connector of the electric fusion welding machine is connected, the welding machine starts to detect whether the electric fusion sleeve has been connected. Usually the resistance value in the electrofusion sleeve is between 0.5 and 10Ω, by applying a low voltage DC voltage U at the output terminal of the electrofusion welding machine t , while detecting the current. If the current is detected and the value is 0.1U t ~2U t In between, the circuit is considered to be connected. After the current is stable, the measured current value through the circuit is I t , then the initial resistance value of the electrofusion sleeve is:

[0043] R 0 = U t I t - - - ( 5 )

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com