Electronic water pump for vehicles and its impeller rotor assembly

A technology of electronic water pumps and components, which is applied to pump components, parts of pumping devices used for elastic fluids, and magnetic circuit rotating parts, etc. It can solve the problems of complex worm support structure, difficult processing, and complicated processing. Achieve the effects of easy integrated molding, low cost of injection molding materials, and simple sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

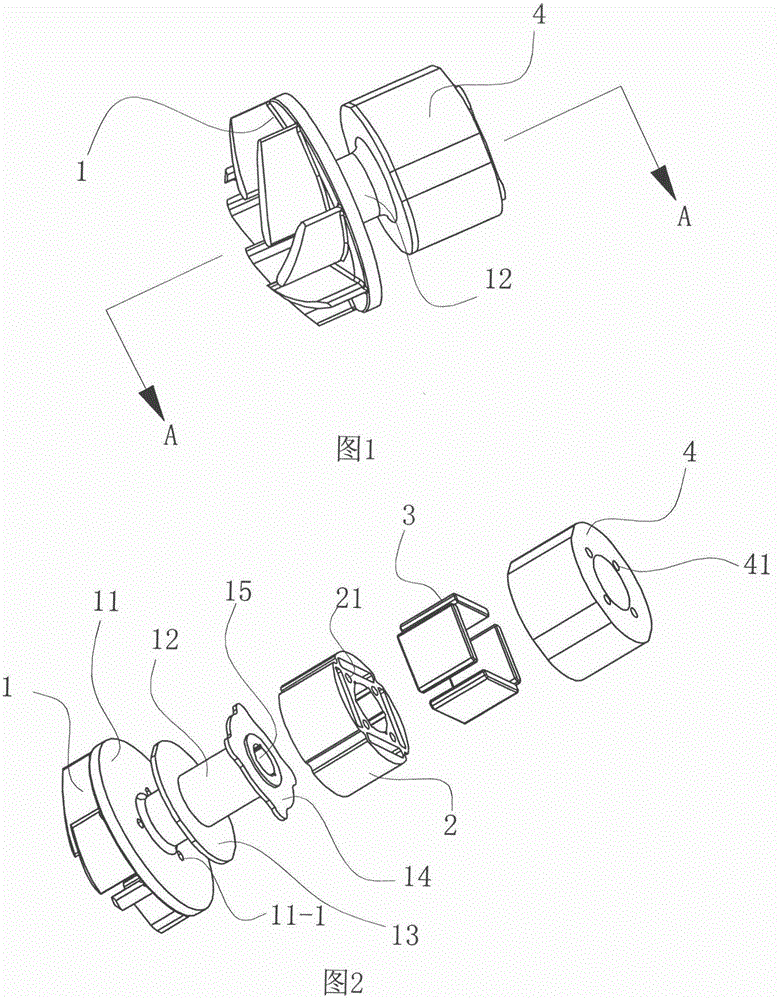

[0039] See Figure 4 to Figure 6 The electronic water pump for vehicles in this embodiment includes a front cover assembly 100 , an impeller rotor assembly, a rotor shaft 5 , a plastic-sealed stator assembly 6 , a motor plastic casing 7 , a sealing ring, a drive circuit board assembly 8 and a rear cover assembly 9 .

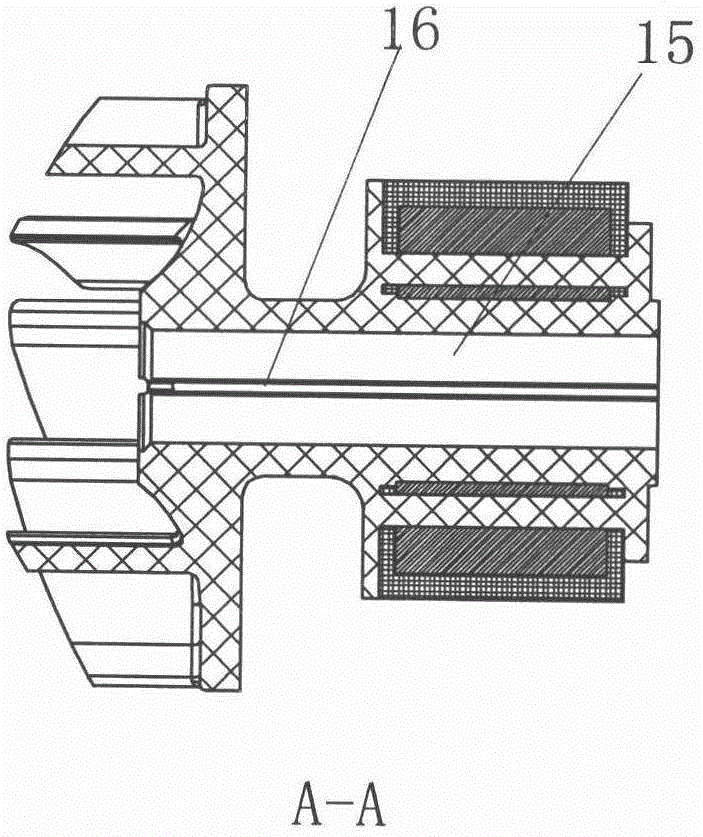

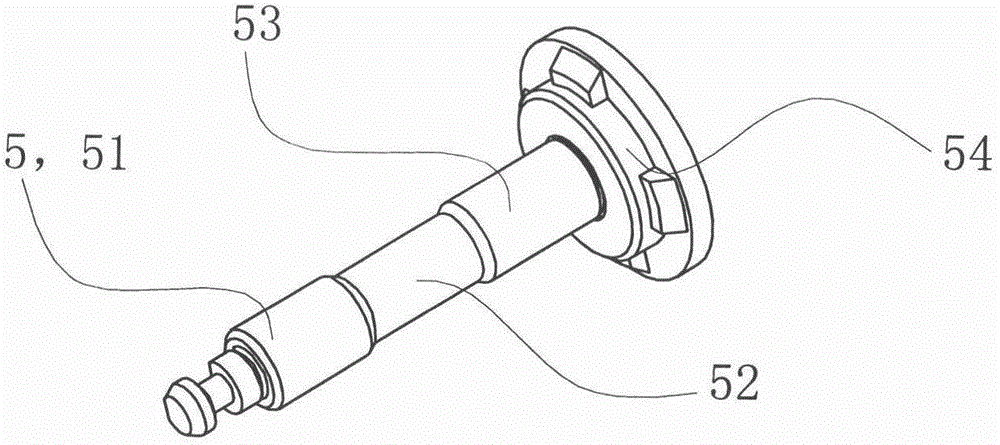

[0040] The plastic-encapsulated stator assembly 6 is completely sealed, and the plastic-enclosed stator assembly 6 is directly injected into the main body of the motor after winding the stator assembly. The stator assembly adopts an upper and lower skeleton structure, which is convenient for winding, and at the same time, it is easy for the motor stator to be integrally formed. After the rotor shaft 5 is pressed into the shaft seat 54 , it is injected together with the plastic-sealed stator assembly 6 .

[0041] The plastic-encapsulated stator assembly 6 and the drive circuit board assembly 8 are fixed in the inner cavity of the motor plastic-encapsulated housin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com