Heterogeneous cold repair welding process for online repairing crack of plug valve of main steam pipeline

A main steam and crack technology, applied in the field of heterogeneous cold repair welding technology, can solve the problems of poor welding effect of main steam pipeline, difficulty in the arrangement of on-site heating devices, and difficulty in ensuring the quality of heat treatment, etc., to achieve guaranteed repair welding quality and plasticity Excellent, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

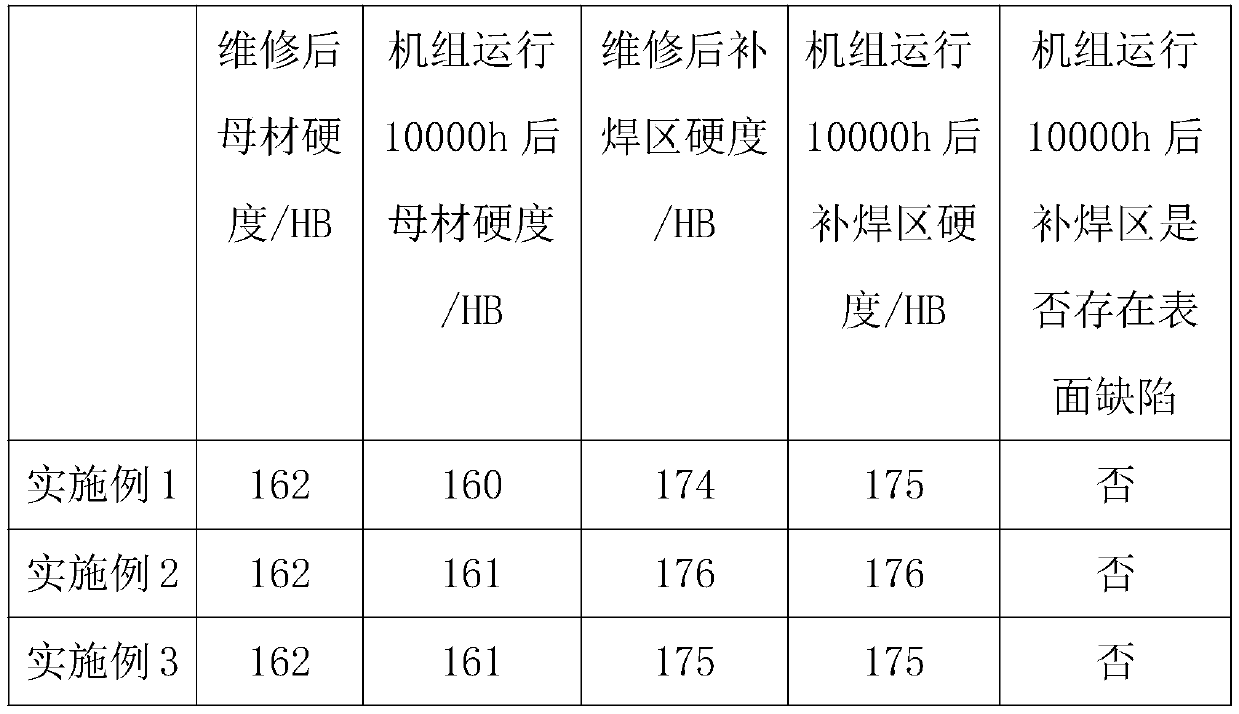

Embodiment 1

[0024] The invention provides a heterogeneous cold repair welding process for on-line repairing of main steam pipeline plugging cracks, and the specific operation steps are as follows:

[0025] Step 1: Judging the direction and depth of cracks, using an angle grinder to grind along the cracks to the depth of the inner wall, and coloring inspection while grinding, until the detection confirms that there are no cracks, measure the crack depth, and use 1 / 3 of the wall thickness as the judgment standard, select Welding method, if the crack depth is greater than 1 / 3 of the wall thickness, the hot welding repair welding process is adopted; if the crack depth is less than 1 / 3 of the wall thickness, and the crack does not extend further in the length direction, the cold welding repair process is used. The welding method selects high-chromium and high-nickel nickel-based welding consumables for repair, and the welding consumables select ENiCrFe-3 welding rods;

[0026] Step 2: Crack pr...

Embodiment 2

[0033] The invention provides a heterogeneous cold repair welding process for on-line repairing of main steam pipeline plugging cracks, and the specific operation steps are as follows:

[0034] Step 1: Judging the direction and depth of cracks, using an angle grinder to grind along the cracks to the depth of the inner wall, and coloring inspection while grinding, until the detection confirms that there are no cracks, measure the crack depth, and use 1 / 3 of the wall thickness as the judgment standard, select Welding method, if the crack depth is greater than 1 / 3 of the wall thickness, the hot welding repair welding process is adopted; if the crack depth is less than 1 / 3 of the wall thickness, and the crack does not extend further in the length direction, the cold welding repair process is used. The welding method selects high-chromium and high-nickel nickel-based welding consumables for repair, and the welding consumables select ENiCrFe-3 welding rods;

[0035] Step 2: Crack pr...

Embodiment 3

[0042] The invention provides a heterogeneous cold repair welding process for on-line repairing of main steam pipeline plugging cracks, and the specific operation steps are as follows:

[0043] Step 1: Judging the direction and depth of cracks, using an angle grinder to grind along the cracks to the depth of the inner wall, and coloring inspection while grinding, until the detection confirms that there are no cracks, measure the crack depth, and use 1 / 3 of the wall thickness as the judgment standard, select Welding method, if the crack depth is greater than 1 / 3 of the wall thickness, the hot welding repair welding process is adopted; if the crack depth is less than 1 / 3 of the wall thickness, and the crack does not extend further in the length direction, the cold welding repair process is used. The welding method selects high-chromium and high-nickel nickel-based welding consumables for repair, and the welding consumables select ENiCrFe-3 welding rods;

[0044] Step 2: Crack pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com