Shielding type permanent-magnetism high-speed motor of submersible pump

A shielded, submersible pump technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of increased power consumption, reduced work efficiency, easy heating of the motor, etc., to prevent heating or overheating, prolong service life, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

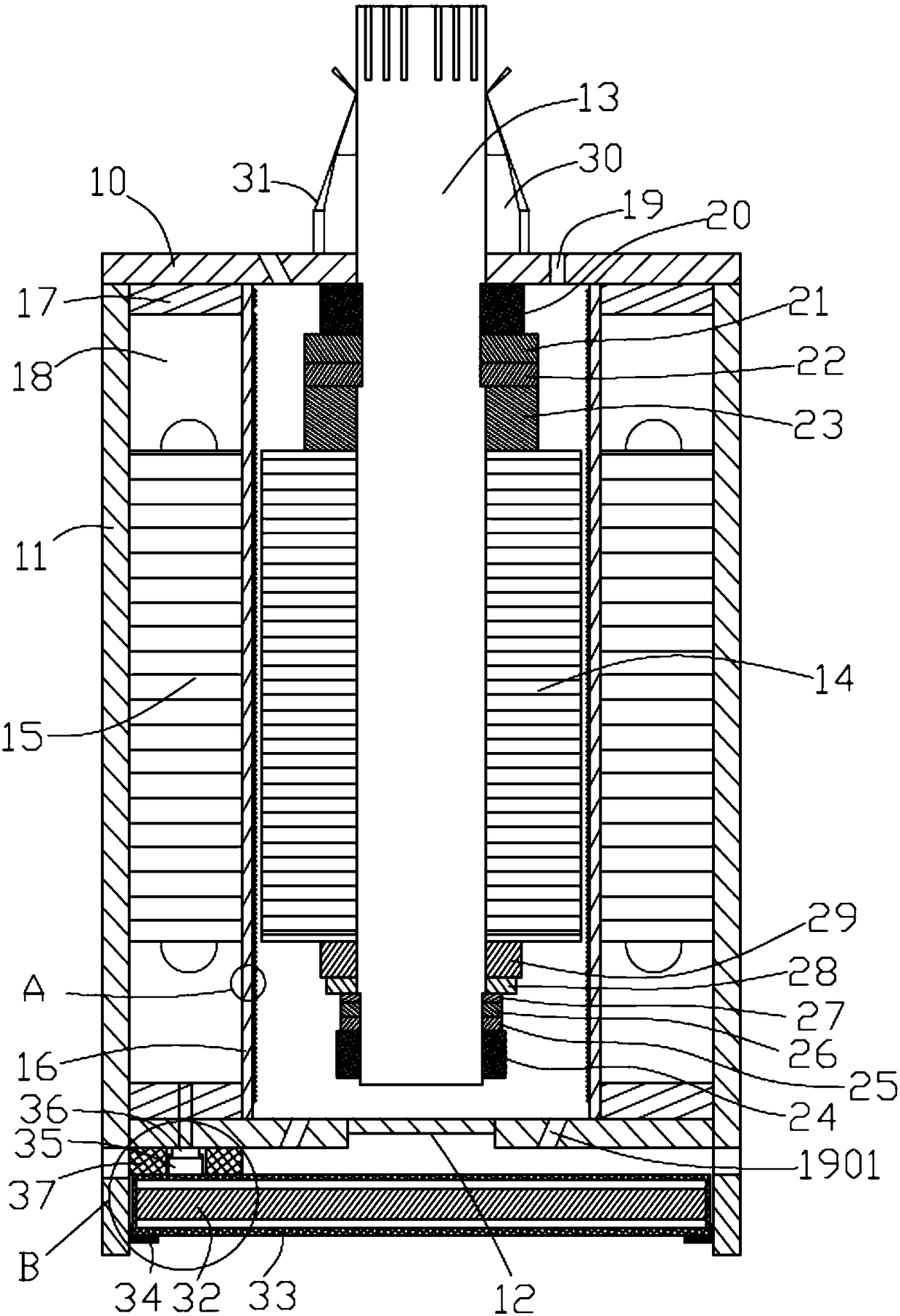

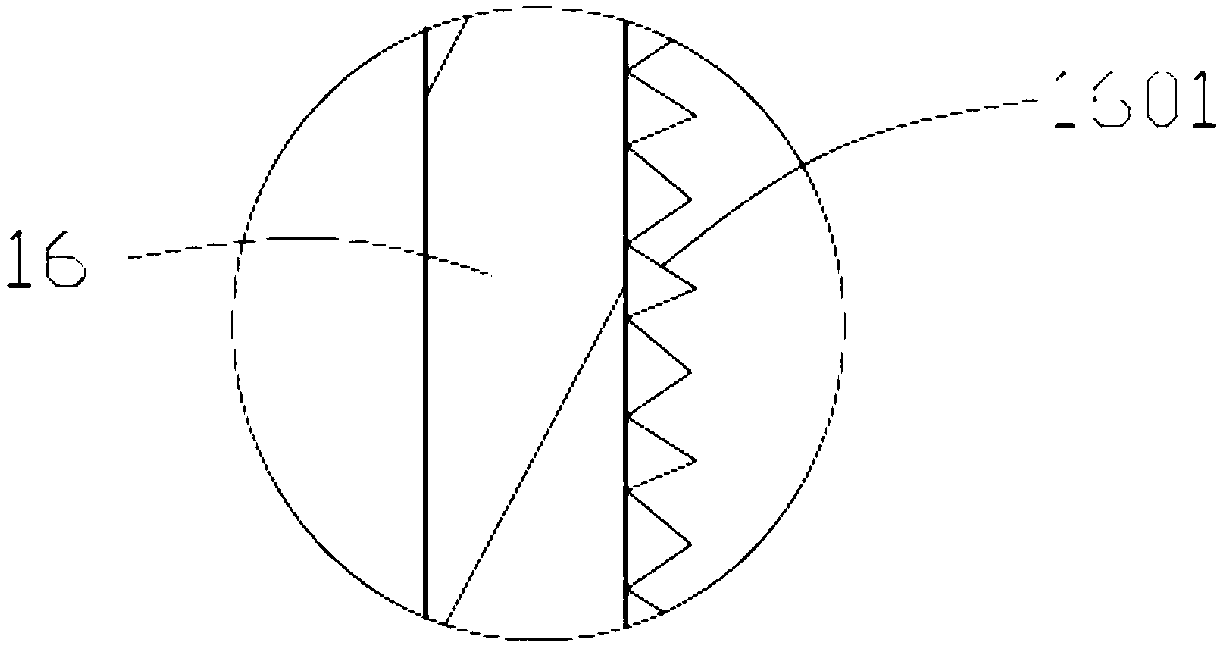

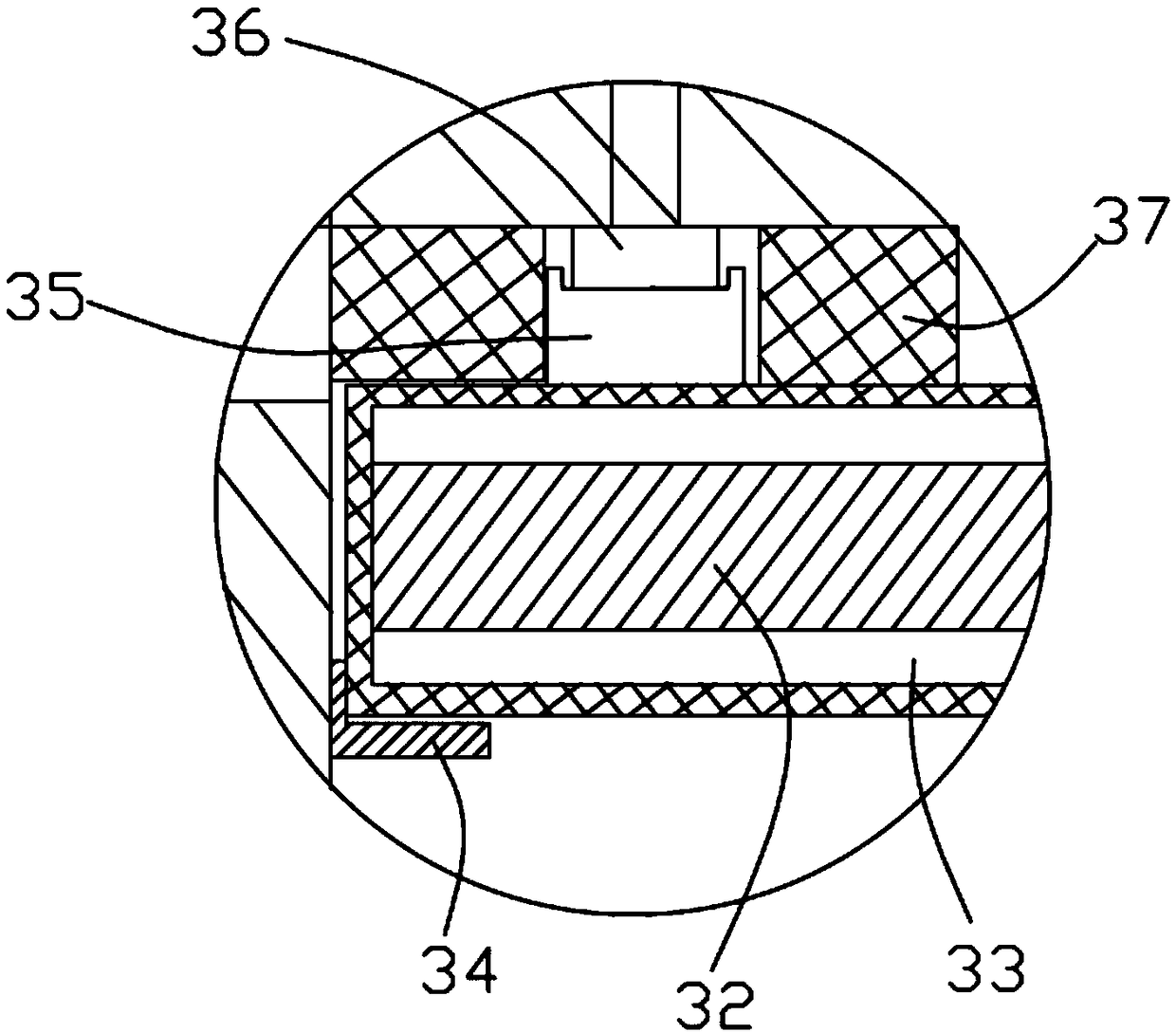

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4: Shielded permanent magnet high-speed submersible pump motor, including a motor casing 11, an upper end cover 10, a lower end cover 12, a rotor shaft 13, a rotor 14 and a stator 15, and the upper end cover 10 and the lower end cover 12 are respectively provided with inlet Water holes 19 and water outlet holes 1901, the stator 15 is fixed on the inner wall of the motor housing 11, wherein a shielding sleeve 16 is arranged between the stator 15 and the rotor 14, the shielding sleeve 16 is in close contact with the stator 15, and is in close contact with the rotor 14 is provided with a gap, the top and bottom of the stator 15 are provided with a shielding seat 17, the shielding sleeve 16 and the shielding seat 17 are fixedly connected by cold welding, and combined with the inner wall of the motor casing 11 to form a shielding chamber 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com