Metal cold-welding additive manufacturing method

A technology of additive manufacturing and cold welding, which is applied in the field of metal cold welding additive manufacturing, can solve the problems of large grain structure and difficult path planning, and achieve the effect of small grain structure, convenient forming quality and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

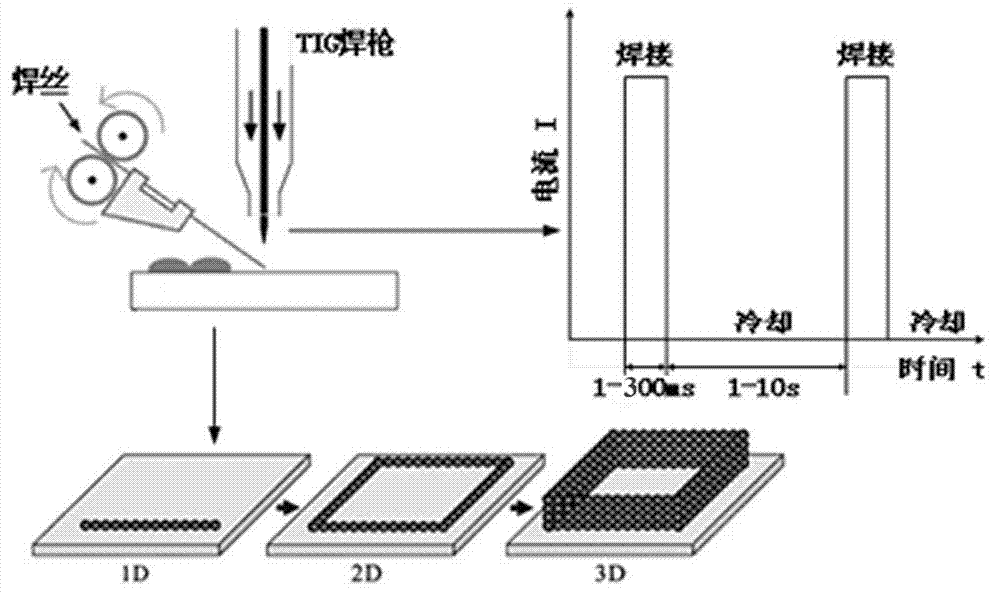

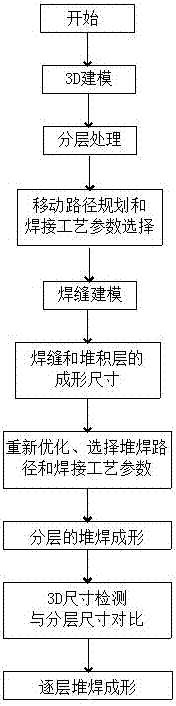

Method used

Image

Examples

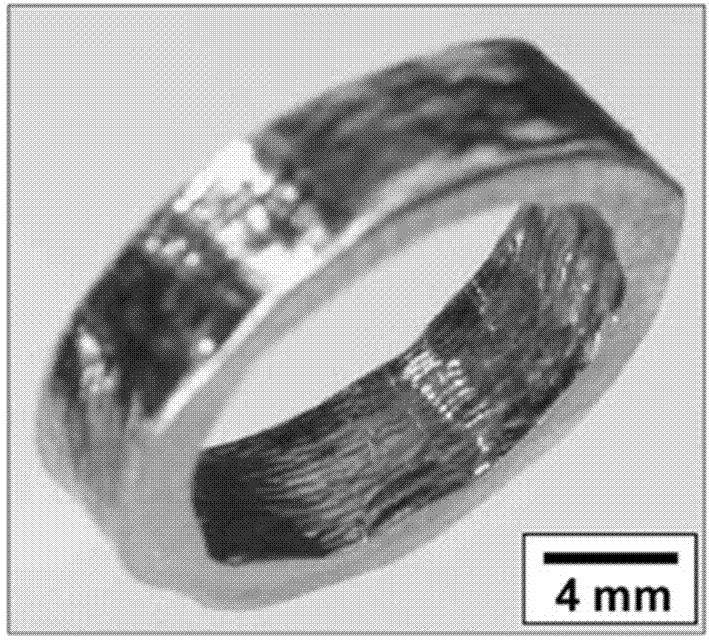

Embodiment 1

[0035] Such as image 3 Shown: the outer diameter 20mm of titanium ring, height 4mm, wall thickness 2mm, be formed by surfacing welding of 80 layers of ring parts, the height of every layer of ring parts is 0.2mm; The concrete steps of its manufacturing method are:

[0036] Step 1: Carry out 3D modeling of the titanium metal ring on the main control computer, carry out layering processing on the titanium metal ring, obtain the size and shape characteristics of each layer, and then plan the moving path of the welding torch and select its Welding process parameters, where the pulse current is 50-100A, the diameter of the welding wire is 0.5mm Ti5Al2.5Sn, the wire feeding speed is 0.1m / min-0.2m / min, and the welding speed is 0.2mm / s-0.5mm / s, the weld width is 0.2-2mm;

[0037]Step 2: Establish the corresponding weld model for the layer through the welding process parameters and the planned moving path of each weld selected above; The three-dimensional model of the layer is used...

Embodiment 2

[0041] Such as Figure 4 Shown: the height of double helix titanium metal post is 20mm, the diameter of single helix titanium metal post is 1.5mm, and the maximum spacing between two single helix titanium metal posts is 5mm; The specific steps of its manufacturing method are:

[0042] Step 1: Carry out 3D modeling on the double-helix titanium metal column on the main control computer, process the double-helix titanium metal column in layers, obtain the size and shape characteristics of each layer, and then plan the moving path of the welding torch and Select its welding process parameters, wherein, the pulse current is 30-40A, and the diameter of the welding wire is 0.3mm TC4 titanium alloy welding wire, wherein, there are 4-6 parts of Al, 2.5-4 Part V, 0.01-0.02 part C, 0.1-0.2 part O and 0.003-0.005 part N, the rest is Ti, the wire feeding speed is 0.1m / min-0.2m / min, the welding speed is 0.2mm / s- 0.3mm / s, the weld width is 0.5-1.5mm;

[0043] Step 2: Establish the correspo...

Embodiment 3

[0047] Such as Figure 5 Shown: the height of titanium metal miniature tower is 2.5mm, and the side length of its bottom square is 2.5mm; The concrete steps of its manufacturing method are:

[0048] Step 1: Carry out 3D modeling of the titanium miniature tower on the main control computer, process it in layers, obtain the size and shape characteristics of each layer, and then plan the moving path of the welding torch and select its welding process parameters , where the pulse current is 40-60A, the diameter of the welding wire is 0.4mm titanium alloy welding wire, the wire feeding speed is 0.1m / min-0.2m / min, and the welding speed is 0.2mm / s-0.4mm / s, Weld width is 0.5-1.5mm;

[0049] Step 2: Establish the corresponding weld model for the layer through the welding process parameters and the planned moving path of each weld selected above; The three-dimensional model of the layer is used to obtain the size of the weld and the build-up layer; compare the size of the build-up lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com