Welding process for repairing crack of ball milling iron casting

A welding process, the technology of ball-ground cast iron, which is applied in the field of welding, can solve the problems of affecting the spare parts of ball-ground cast iron and the easy formation of cold cracks, etc., and achieve the effect of simplifying the implementation process, not easy to crack, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

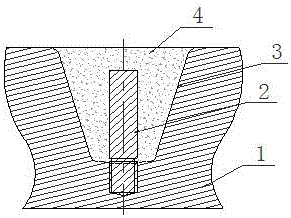

[0015] See figure 1 , The welding process for repairing cracks of ball milled iron castings of the present invention includes:

[0016] (1) Use a plasma cutting machine to cut the beveled U-shaped welding groove along the crack, and then use an angle grinder to thoroughly polish the carburized and sulfide layer on the inner surface of the bevel groove, and then polish the bottom of the groove. Cut into a reverse arch.

[0017] (2) At the bottom of the bevel U-shaped groove, use an alloy drill to drill and tap, and embed multiple high-strength bolts (such as M14 high-strength bolts). The sum of the surface area of the multiple bolts accounts for no less than the surface area of the groove opening 30%. Practice has verified that the number of embedded bolts cannot exceed 30%, otherwise the weld area will become smaller, which will affect the amount of weld fusion and weld strength. The purpose of selecting planted wire welding is to root the weld meat and the base metal, enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com