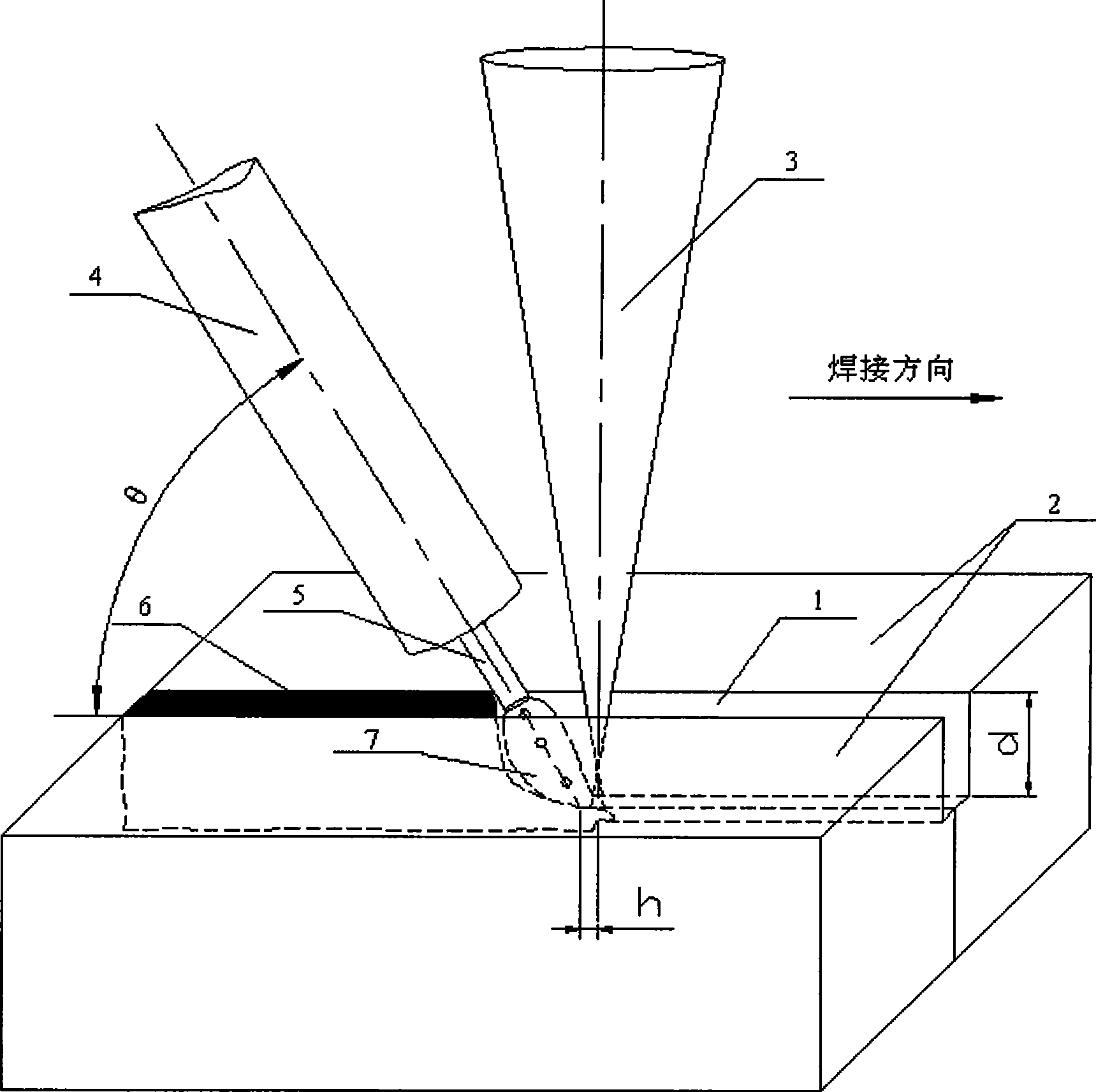

Laser-arc composite heat-source narrow-gap precision welding method

A compound heat source and precision welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult precision welding, lower laser welding efficiency, large arc geometry, etc., to achieve high-quality welding, welding effect and Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] best practice

[0023] The laser used in the test is the HL2006D Nd:YAG solid-state laser produced by the German HAAS company, with a maximum output power of 2.6KW and a continuous laser wave with an output wavelength of 1.06μm, and a focusing lens with a focal length of 200mm; the arc welding machine is produced by the Austrian F0NIUS company TPS5000 digital GMA welding power supply and wire feeder; the test materials used are 38CrMoAlA nitriding steel and 1Cr17Ni2 martensitic stainless steel, and the size of the test plate is 200mm×40mm×8mm; the diameter developed by Harbin Welding Research Institute is Φ1. 0mm 309 stainless steel wire. The test plate adopts the narrow gap formed by "I" and rectangular groove respectively. The groove size is 0.8mm in width and 3.0mm in depth and 0.8mm in width and 3.5mm in depth. Preset solder.

[0024] The specific welding specification parameters are as follows:

[0025] The welding speed is 1.0m / min, the wire feeding speed is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com