Continuous shocking tool

A technology of tools and jackets, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of reduced jarring efficiency, poor jarring effect, and damage to operating strings, so as to improve reliability and beautiful appearance degree, the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

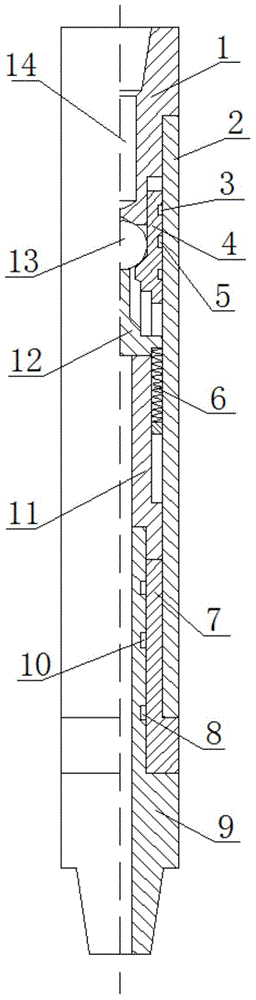

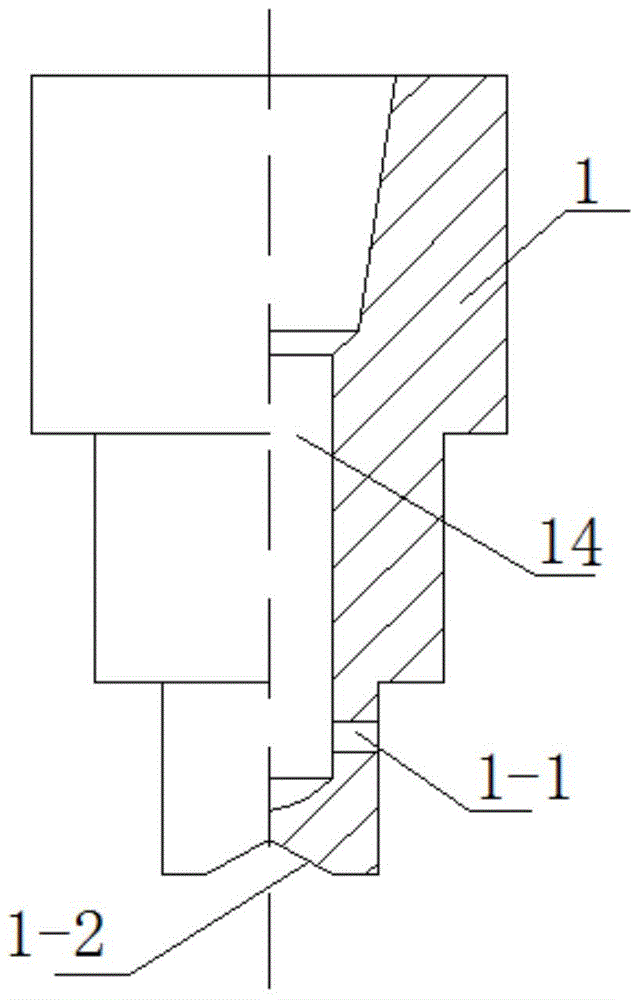

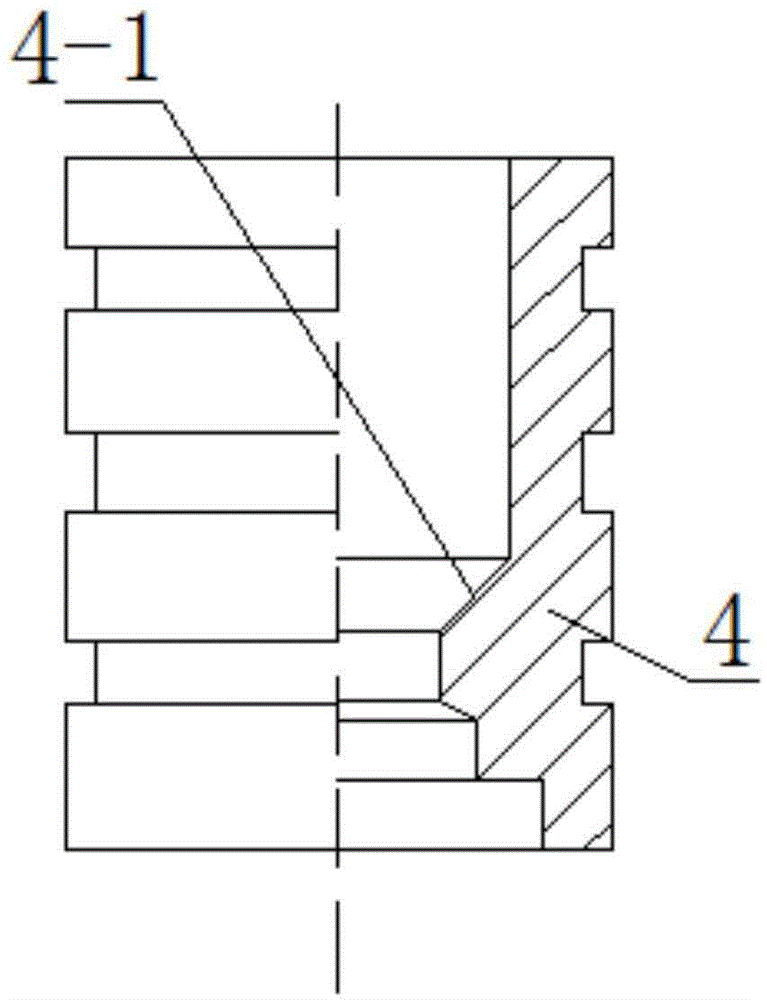

[0023] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a continuous jarring tool includes an upper joint 1, a jacket 2 with a middle hole, a piston 4, a shuttle key 12, a plunger 11, a sliding sleeve 7 with a middle hole, and a lower joint 9. 2 is inserted into the middle hole of the jacket 2, and is threaded and sealed with the top of the jacket 2. The middle part of the upper joint 1 is provided with a flow groove 14 vertically, and a communication groove 14 is opened on the side wall of the flow groove 14. The diversion hole 1-1 of the middle hole of the outer casing 2, the bottom of the upper joint 1 is provided with a tapered groove 1-2, the piston 4 is vertically sealed in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com