Preparation method of novel acidified corrosion inhibitor and use thereof

A corrosion inhibitor and oil well acidizing technology, which is applied in the fields of earthwork drilling, organic chemistry, wellbore/well components, etc., can solve the problems of high cost, limited source of raw materials, and restrictions on the wide application of imidazoline corrosion inhibitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 is used to illustrate the experimental synthesis scheme and preparation method of imidazoline quaternary ammonium salt.

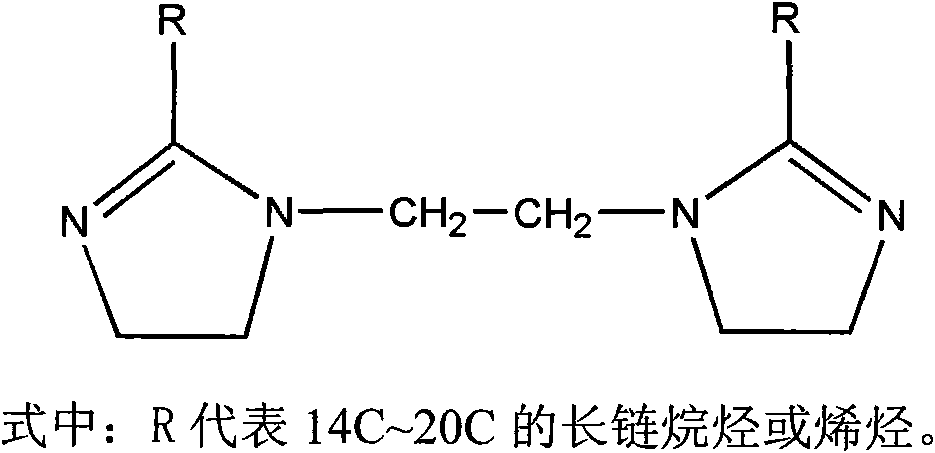

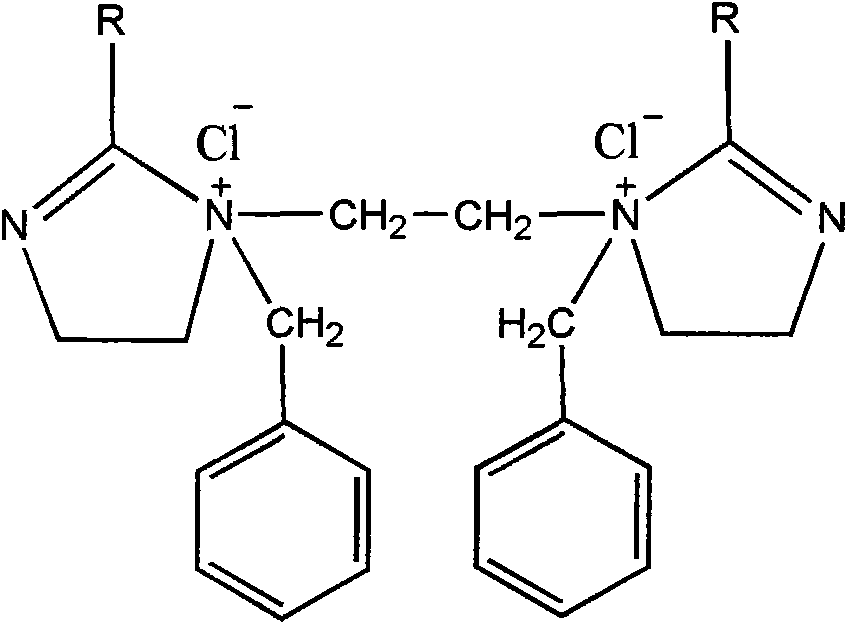

[0020] The experimental synthesis scheme of imidazoline quaternary ammonium salt is shown in Scheme 1:

[0021] Scheme 1:

[0022]

[0023] The specific synthesis method is as follows:

[0024] Take cottonseed oil and triethylenetetramine in a mass ratio of 1.84:1 and place them in a dry reactor, add a certain amount of xylene and 0.25% boric acid as a catalyst, N 2 Under protection, react at 140-160°C for 2 hours, connect to a water separator, program temperature rise to 210°C, react for 7 hours, and separate the water generated by the reaction. Replace the rotary evaporation, evaporate a small amount of xylene and water, pour the viscous substance in the flask into a large beaker equipped with a mixed solvent of ethanol, ethyl acetate and petroleum ether (3:3:1) while hot, Cool and remove the supernatant to obtain the cottonseed ...

Embodiment 2

[0025] Embodiment 2 is used to illustrate the compounding of imidazoline quaternary ammonium salt product and propynyl alcohol.

[0026] The synthetic imidazoline quaternary ammonium salt is mixed with 25% of the total mass of propynyl alcohol to obtain the oil field acidizing corrosion inhibitor of the present invention.

Embodiment 3

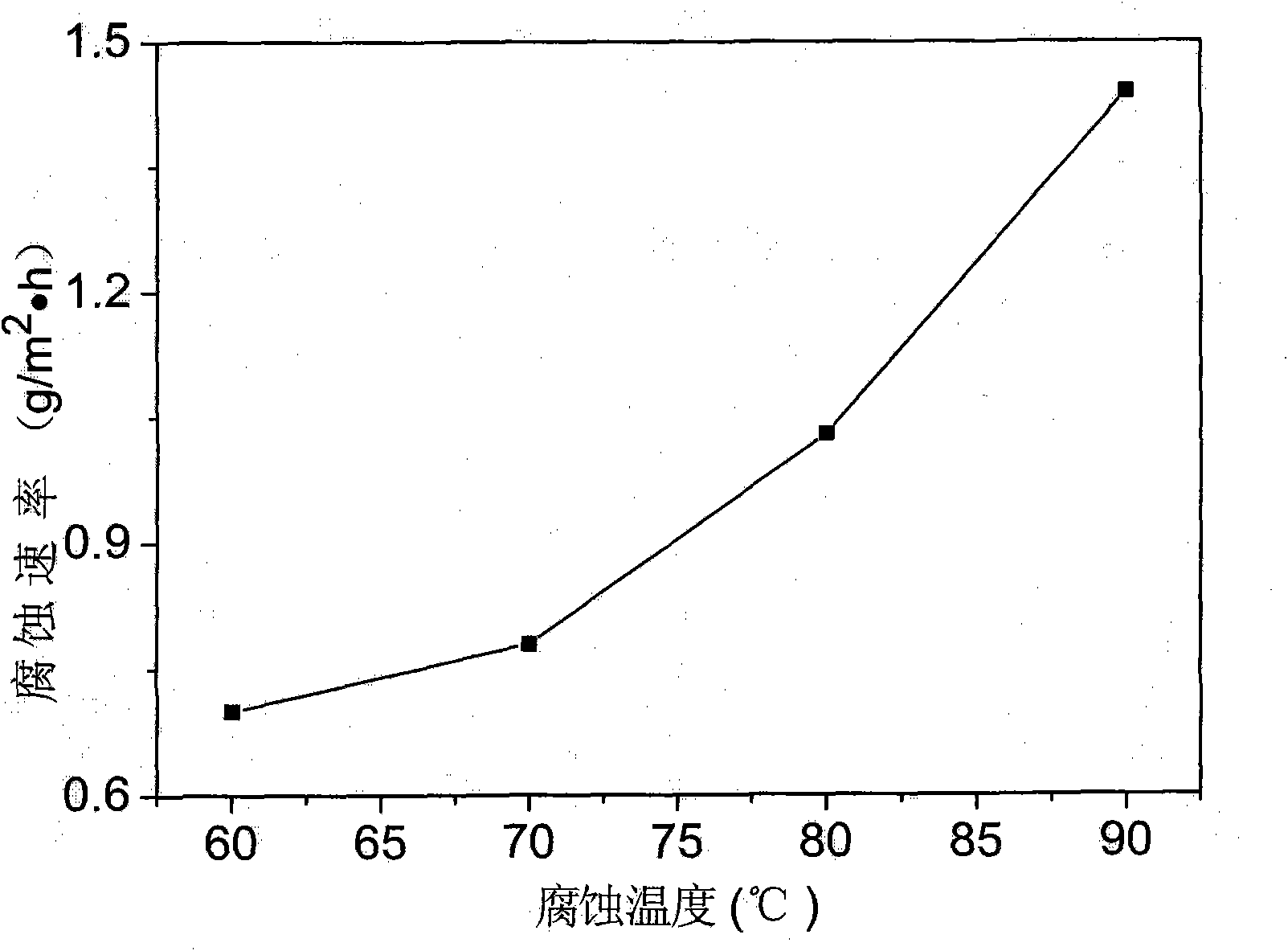

[0027] Example 3 is used to illustrate the research on the corrosion inhibition performance of the oilfield acidizing corrosion inhibitor. According to the test method and evaluation index described in the petroleum and natural gas industry standard SY / T5405-1996 of the People's Republic of China, the performance evaluation of the prepared oilfield acidizing corrosion inhibitor was carried out.

[0028] In 15% HCl environment, the influence of temperature on 0.4% mass concentration oil well acidizing corrosion inhibitor is listed in Table 1.

[0029] Table 1

[0030] Corrosion temperature (℃)

60

70

80

90

Corrosion rate (g / m 2 h)

0.70

0.78

1.03

1.44

[0031] In 60°C, 15% HCl environment, the effect of time on 0.4% mass concentration oil well acidizing corrosion inhibitor is listed in Table 2.

[0032] Table 2

[0033] Corrosion time (h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com