Drillable ball injection sliding sleeve suitable for horizontal well

A ball-throwing sliding sleeve and horizontal well technology, which is applied in earth-moving drilling, wellbore/well components, sealing/packing, etc. Well production, saving construction costs, and highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

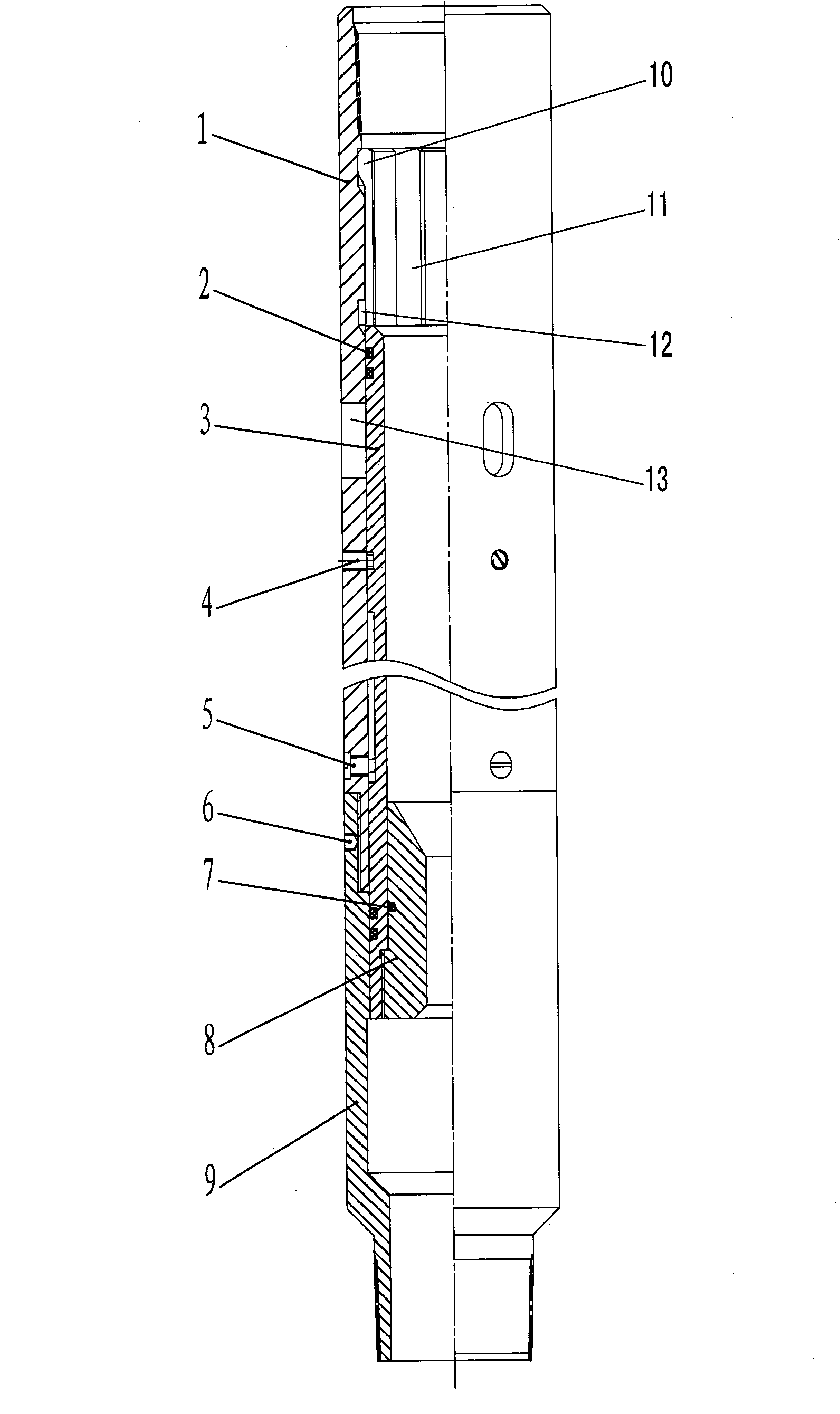

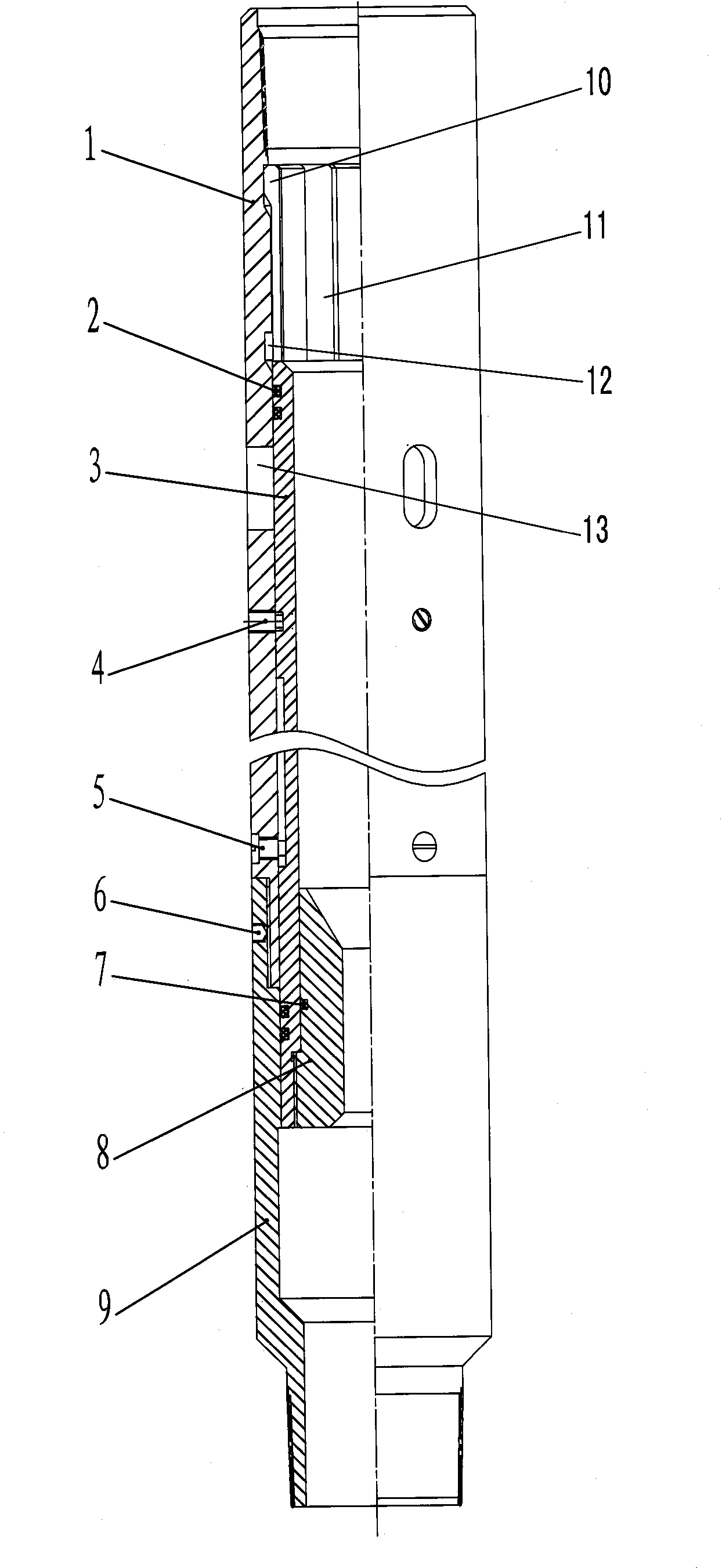

[0014] The present invention includes a joint device and a claw tube structure. The joint device is composed of an upper joint 1 and a lower joint 9. The upper joint 1 and the lower joint 9 are connected together by threads. Screw 6, therefore can realize the fixation after connection of upper and lower joints 1 and 9, the inner circle of the upper end of the upper joint is provided with an upper positioning groove, a lower positioning groove 12 and a side hole 13; 3, the claw tube 3 is arranged in the upper and lower joints 1 and 9, the upper end of the claw tube 3 is provided with a claw 11, there is a gap between the claws 11, and the claw tube 3 and the upper joint 1 are opened by The shear pin 4 and the anti-rotation pin 5 are connected and fixed, and the opening shear pin 4 and the anti-rotation pin 5 connecting the fixed claw tube 3 and the upper joint 1 can realize the axial and circumferential direction between the elastic claw tube 3 and the upper joint 1 Fixed; in o...

Embodiment 2

[0016] The installation sequence of the present invention is: first the seal rings 7 and 2 are respectively placed on the outer circle of the ball seat 8 and the claw tube 3, and the ball seat 8 is connected to the lower end of the claw tube 3, and then the claw tube 3 is Insert it into place from the upper end of the upper joint, install the opening shear pin 4 and the anti-rotation pin 5 at the same time, finally connect the lower joint 9 to the upper joint 1, and tighten the fixing screw 6, thus completing the installation work of the present invention. Completed the preparations for putting into use;

Embodiment 3

[0018] During construction, according to the technical requirements of the staged production increase of the horizontal open-hole well, the claw tube 3 in the sliding sleeve is pressed down by throwing a ball, and the claw boss 10 provided at the upper end of the claw tube 3 is forced to shrink and go down, from the upper joint The upper positioning groove enters the lower positioning groove 12, and the claw tube 3 is locked in reverse, and cannot move upward. At this time, the gap left between the claws 11 is facing the side hole 13 of the upper joint, realizing the ball-type sliding sleeve The opening of the opening, the establishment of the liquid inlet channel for different transformation layers, the opening ball put in is located on the ball seat 8 of the sliding sleeve; The side hole 13 channels flow back, and the special ball for opening the sliding sleeve also flows back from the tubing to the ball catcher on the surface pipeline along with the liquid or gas; if the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com