Titanium alloy and processing method thereof

A processing method and titanium alloy technology, applied in the field of titanium alloy and its preparation method, can solve the problems of impact performance index gap, low longitudinal impact performance index steel, etc., and achieve the effect of meeting the material demand of mining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Batching by weight percentage, smelting Ti-6Al-4V and titanium alloy ingot of the present invention respectively one each, wherein Ti-6Al-4V target composition is Al: 6.0%, V: 4.0%, Ti surplus; Titanium of the present invention The target composition of the alloy ingot is Al: 6.0%, V: 4.0%, Zr: 0.35%, Mo: 0.35%, and the balance of Ti.

[0026] The ingot was smelted twice in a vacuum consumable electric arc furnace. The ingot was heated and forged at 150°C above the phase transition point, with a deformation of 72%, and heated at 40°C below the phase transition point, with a forging deformation of 78%. Heating at the temperature of the phase transition point, the forging deformation is 60%, and the forging is 125mm bar.

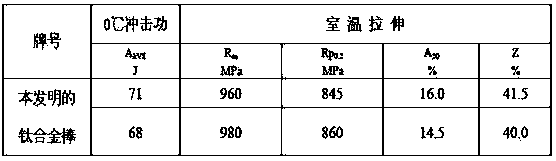

[0027] The performance was tested after being annealed in an air-cooled electric furnace at 700°C for 2 hours, and the data are shown in Table 3.

[0028] Table 3 Tensile properties at room temperature and impact properties at 0°C

[0029]

Embodiment 2

[0031] Batching by weight percentage, smelting Ti-6Al-4V and titanium alloy ingot of the present invention each one respectively, wherein Ti-6Al-4V target composition is Al: 6.5%, V: 4.4%, Ti surplus; Titanium of the present invention Alloy target composition is Al: 6.5%, V: 4.4%, Zr: 0.35%, Mo: 0.35%, Nb: 0.35%, Ti balance 。 The ingot is smelted twice in a vacuum consumable electric arc furnace. The ingot is heated and forged at 200 °C above the phase transition point, with a deformation of 75%. When heated at 40 °C below the phase transition point, the forged deformation is 70%. The 260mm billet is drilled and bored and the outer surface is machined to prepare an ingot for extrusion, and then heated and extruded at the temperature of the phase transition point to extrude into 108 22mm pipe, extrusion deformation is 90%.

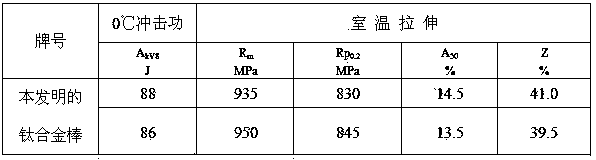

[0032] After heat preservation at 650°C for 2 hours, the performance was tested after furnace cooling and vacuum annealing. The data are shown in Tabl...

Embodiment 3

[0035] Batching according to weight percentage, smelting one titanium alloy ingot of the present invention, the target composition is Al: 5.8%, V: 3.8%, Zr: 1.5%, Mo1.0%, Nb: 0.6%, Ti balance 。 The ingot was smelted twice in a vacuum consumable electric arc furnace. The ingot was heated and forged at 100°C above the phase transition point, with a deformation of 62%, and heated at 50°C below the phase transition point, with a forging deformation of 67%. Heating at the temperature of the phase transition point, the forging deformation is 69%, and the forging is 125mm bar.

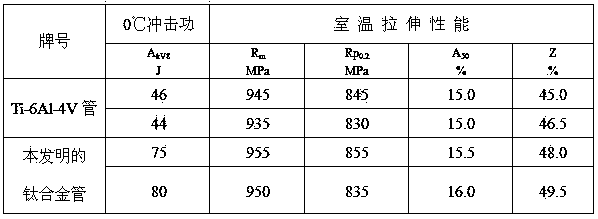

[0036] The performance was tested after being annealed in an air-cooled electric furnace at 700°C for 2 hours, and the data are shown in Table 5.

[0037] table 5

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com