Simulation and optimization system of flue gas desulfurization process of thermal power plant

A technology for process simulation and wet flue gas desulfurization, which is applied in the field of simulation and optimization system software for flue gas desulfurization process in thermal power plants, which can solve problems such as potential safety hazards, increased chip operating load, and system impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

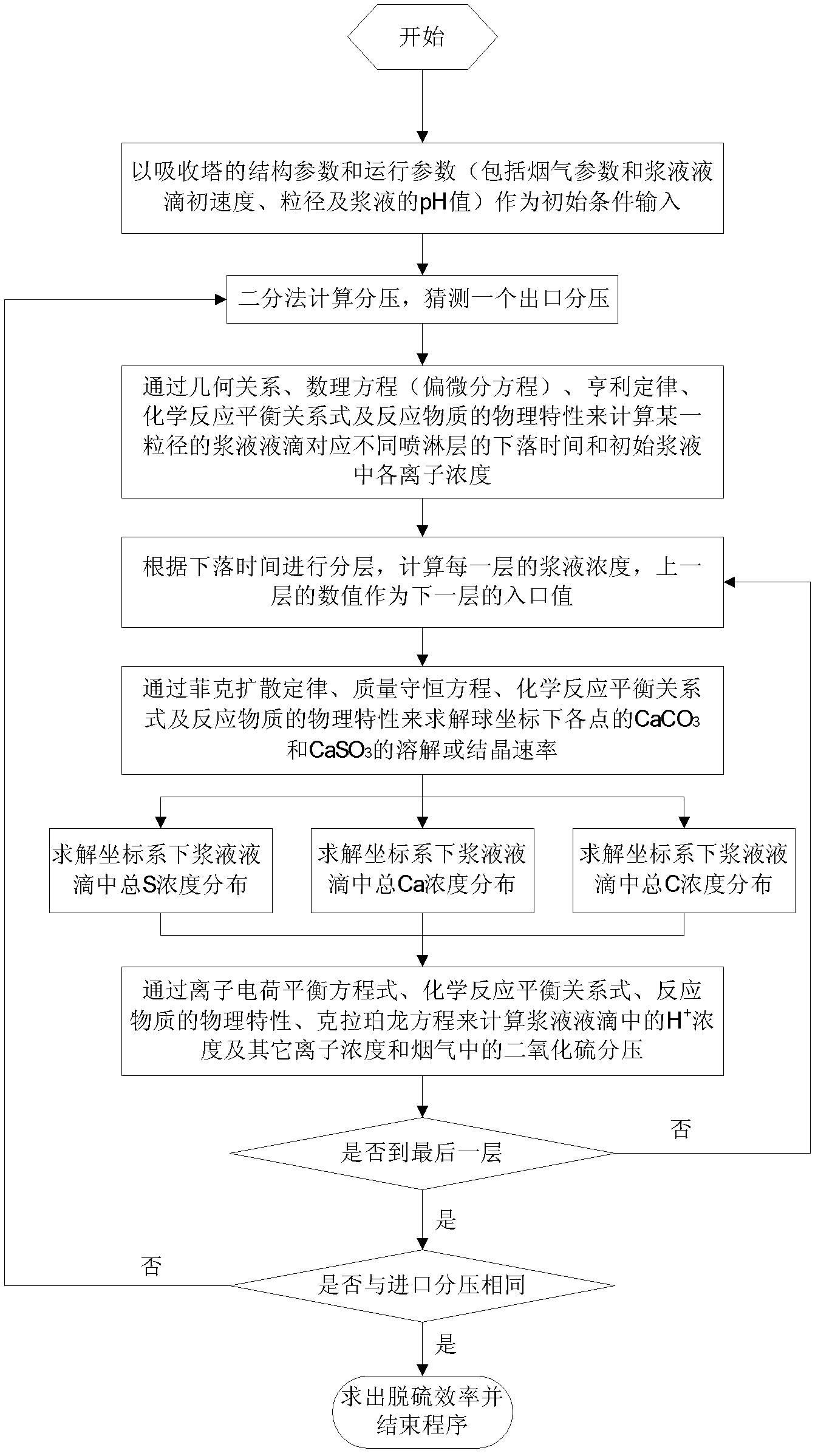

Method used

Image

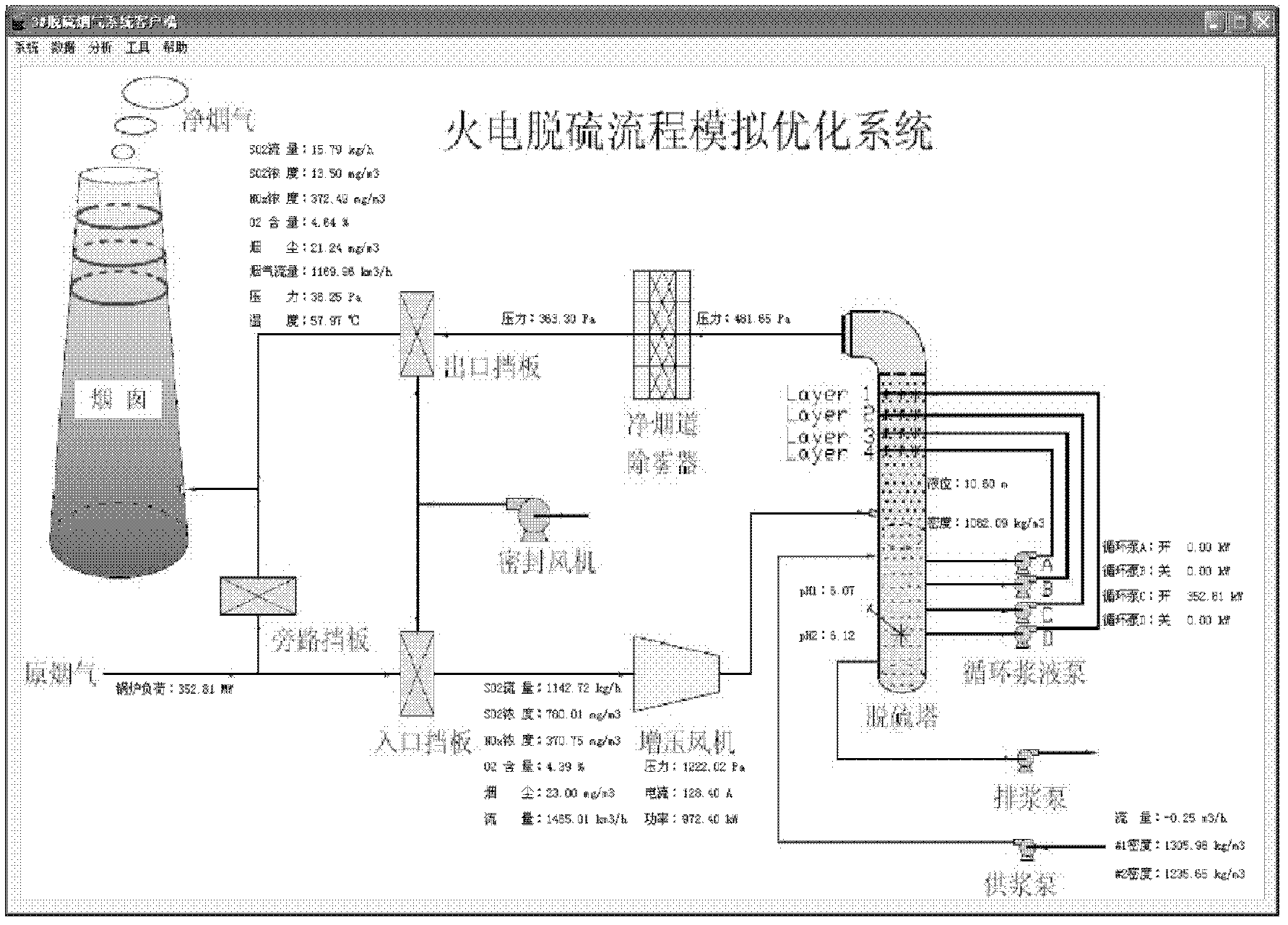

Examples

Embodiment

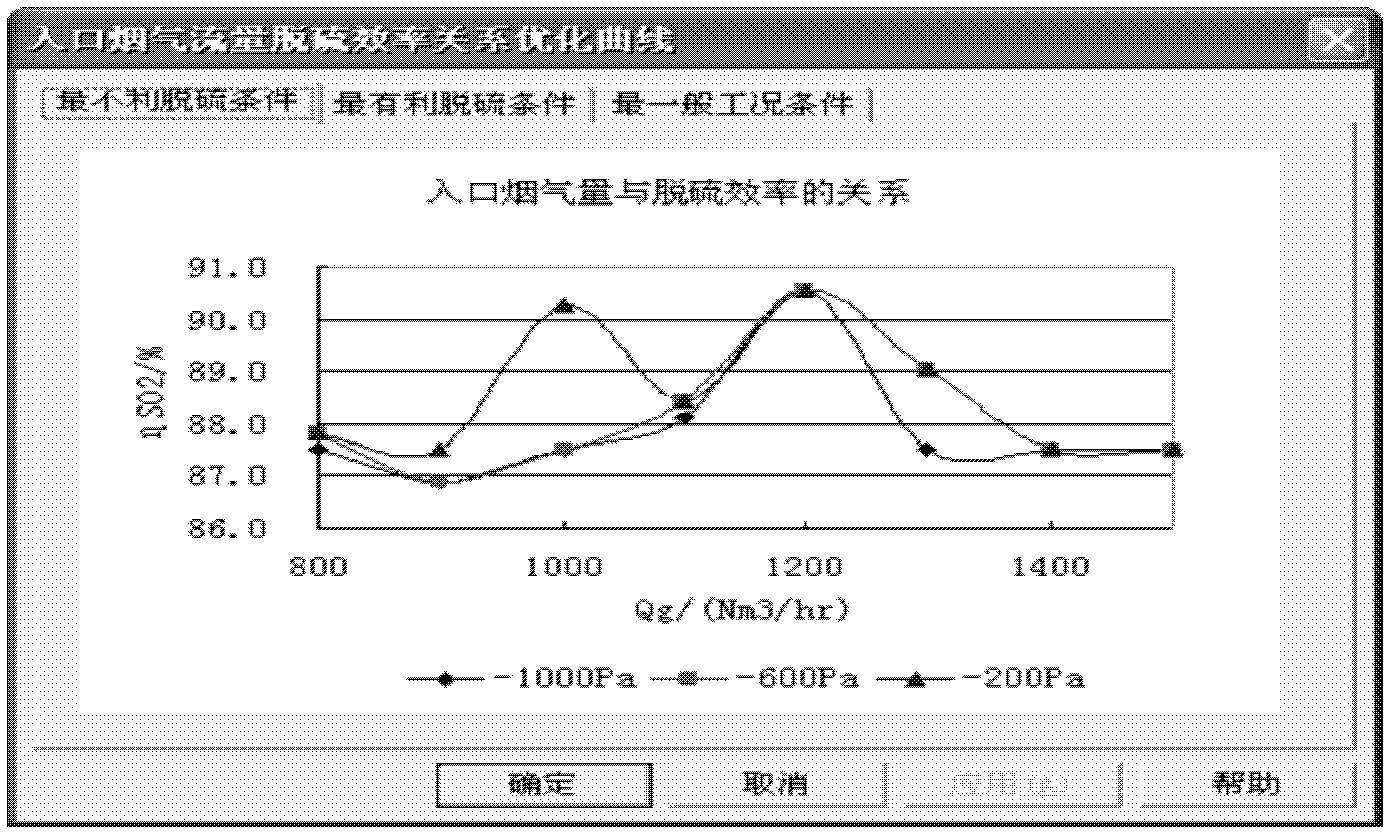

[0167] For a four-layer spray flue gas desulfurization absorption tower equipped with 4 slurry circulation pumps. The fluctuation range of flue gas flow is 800 ~ 1500kNm 3 / hr. Flue gas inlet SO 2 The concentration fluctuation range is 800 ~ 5000mg / Nm 3 . Flue gas inlet gauge pressure fluctuation range is -1000~1000Pa.

[0168] 1, Build an optimized operation database

[0169] Compile the desulfurization process calculation model according to the instructions.

[0170] Set optimization goals according to relevant desulfurization policies, emission standards and other binding indicators: SO 2 The emission reduction is the largest while the power consumption is the lowest, and the desulfurization efficiency can reach 95% or SO 2 The emission concentration is lower than the requirement of 105mg / L. The weighting method is used for normalization processing, with sewage charges and electricity charges as weights, and the goal after normalization is economic benefits.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com