Automatic wall building machine

A wall-laying machine, automatic technology, applied in construction, building construction, processing of building materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

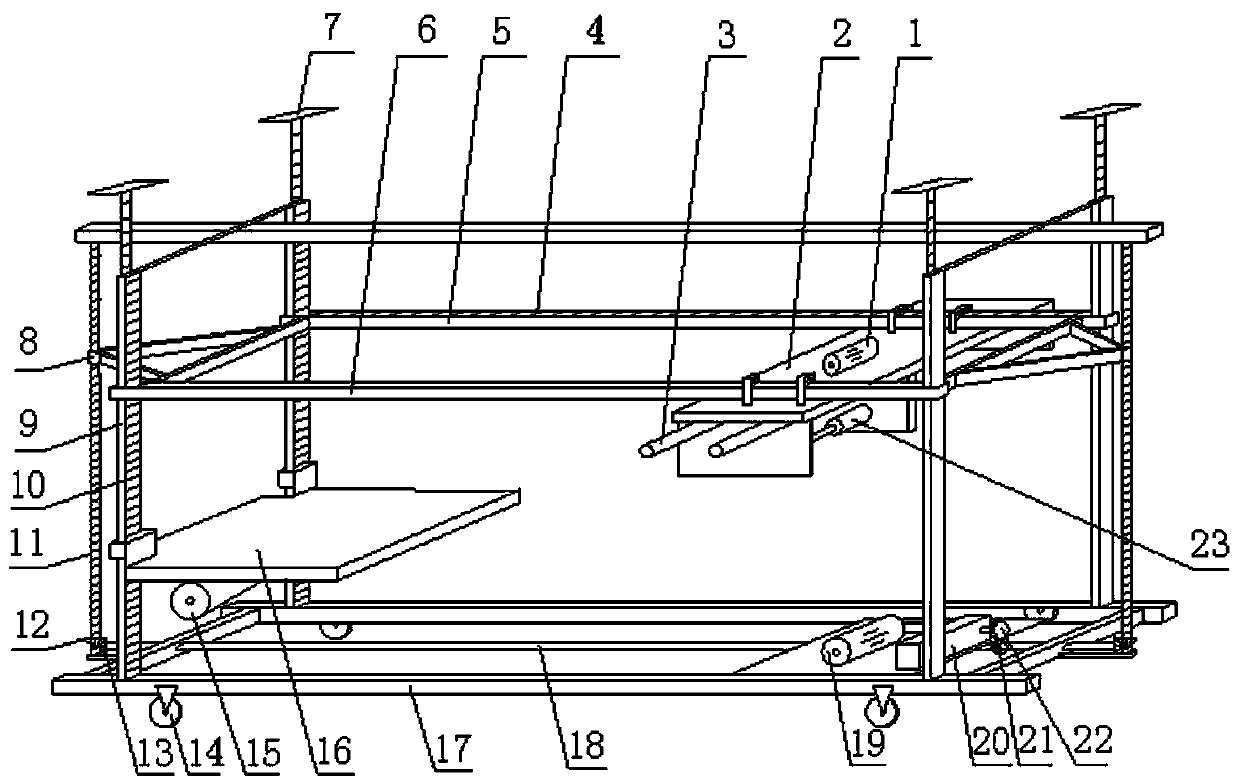

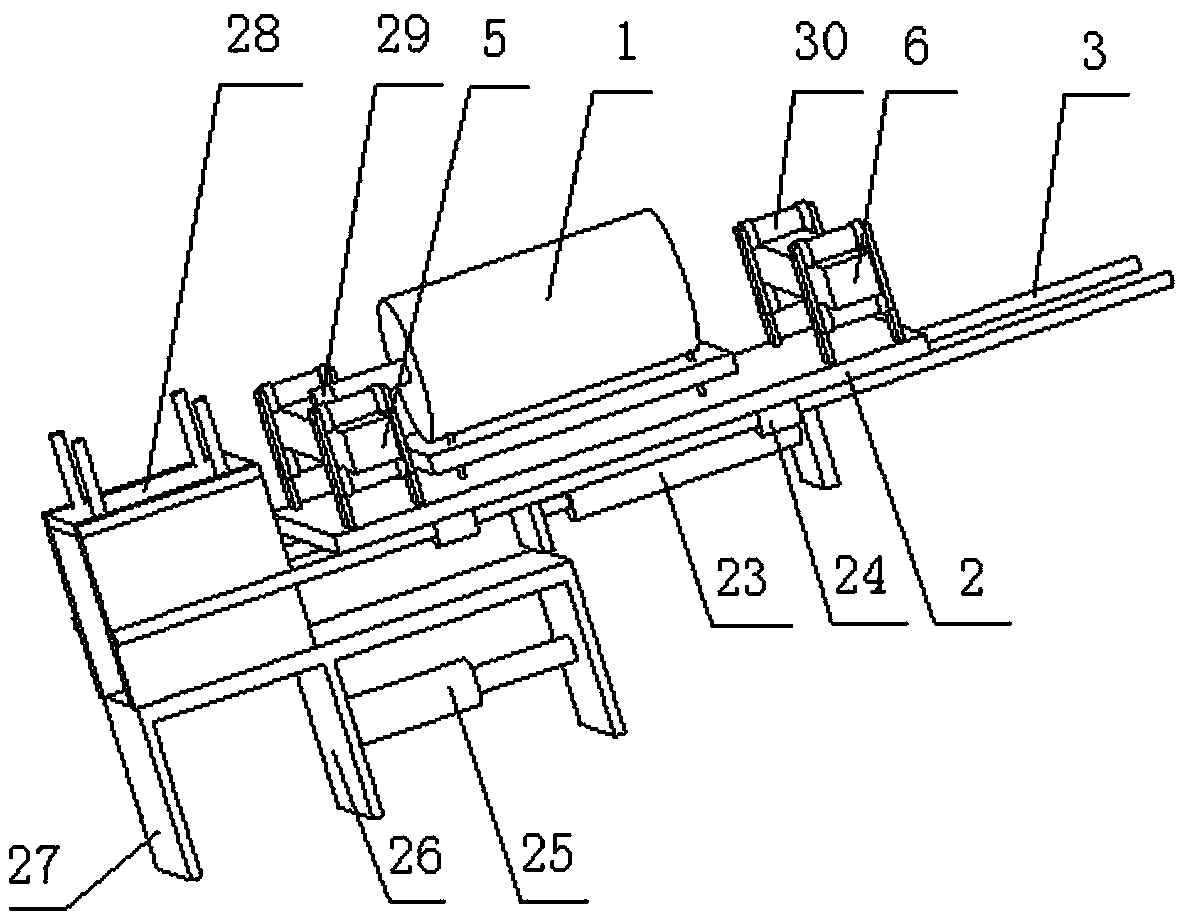

[0016] Below in conjunction with accompanying drawing, the structure of automatic wall-laying machine of the present invention is described in detail.

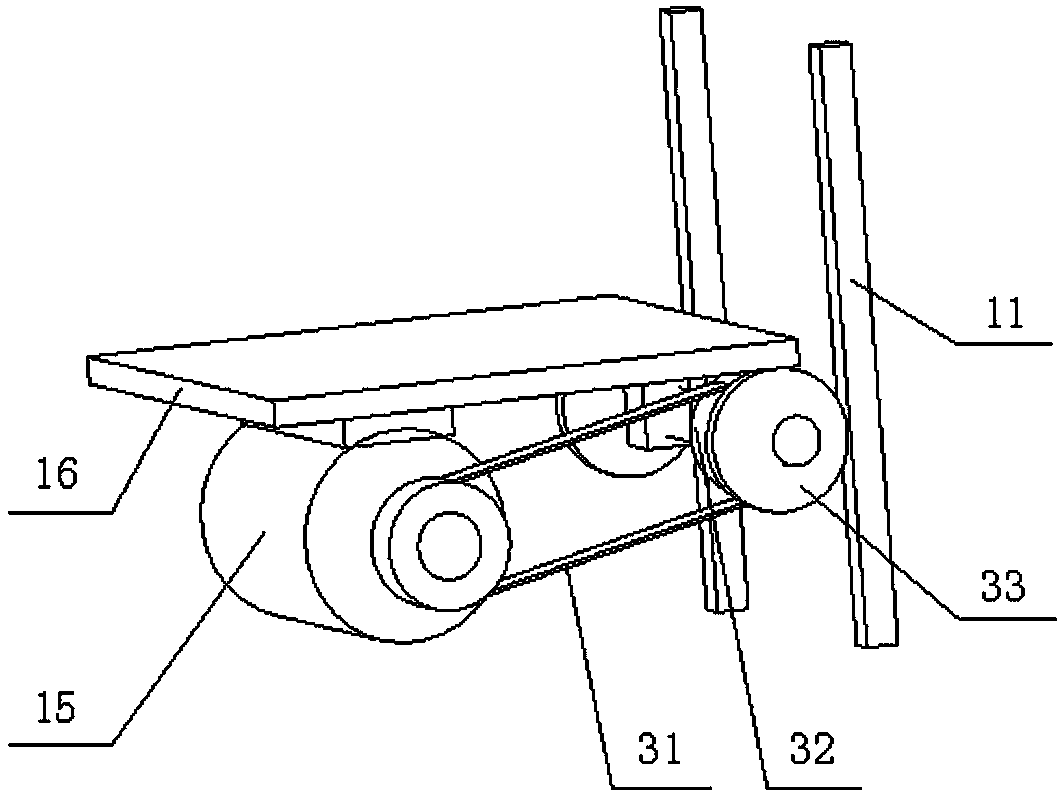

[0017] see figure 1 , figure 2 , image 3 , the structure of the automatic wall-laying machine of the present invention comprises a frame base 17, and pillars 9 are respectively set up at four corners of the frame base 17, and upper brick pallets 16 driven up and down by a tray motor 15 are established on two columns at one end of the frame base 17, specifically The rack 10 is laid on the column next to the upper brick tray 16, and two gears 33 are arranged at the end of the upper brick tray 16, each gear 33 meshes with the corresponding rack 10, and the tray motor 15 passes through a transmission device such as a belt 31 or a chain. Drive the runner 32 on the two gears 33 shafts to drive the two gears 33 to move, thereby realizing that the upper brick tray 16 moves up and down along the rack 10. A crossbeam 5,6 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com