Casing structure with leaf apex interval control and leaf tip flow control

A technology of flow control and blade tip clearance, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of blade tip leakage loss, large thermal expansion deformation, etc., to reduce leakage loss, easy processing, and reduce diameter effect on deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

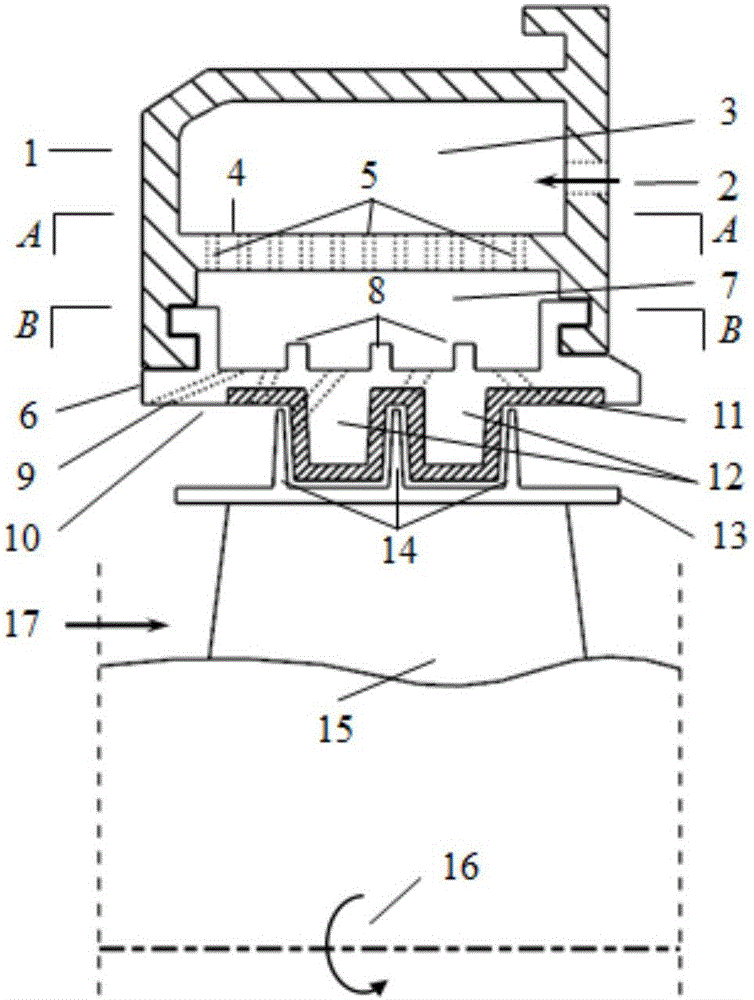

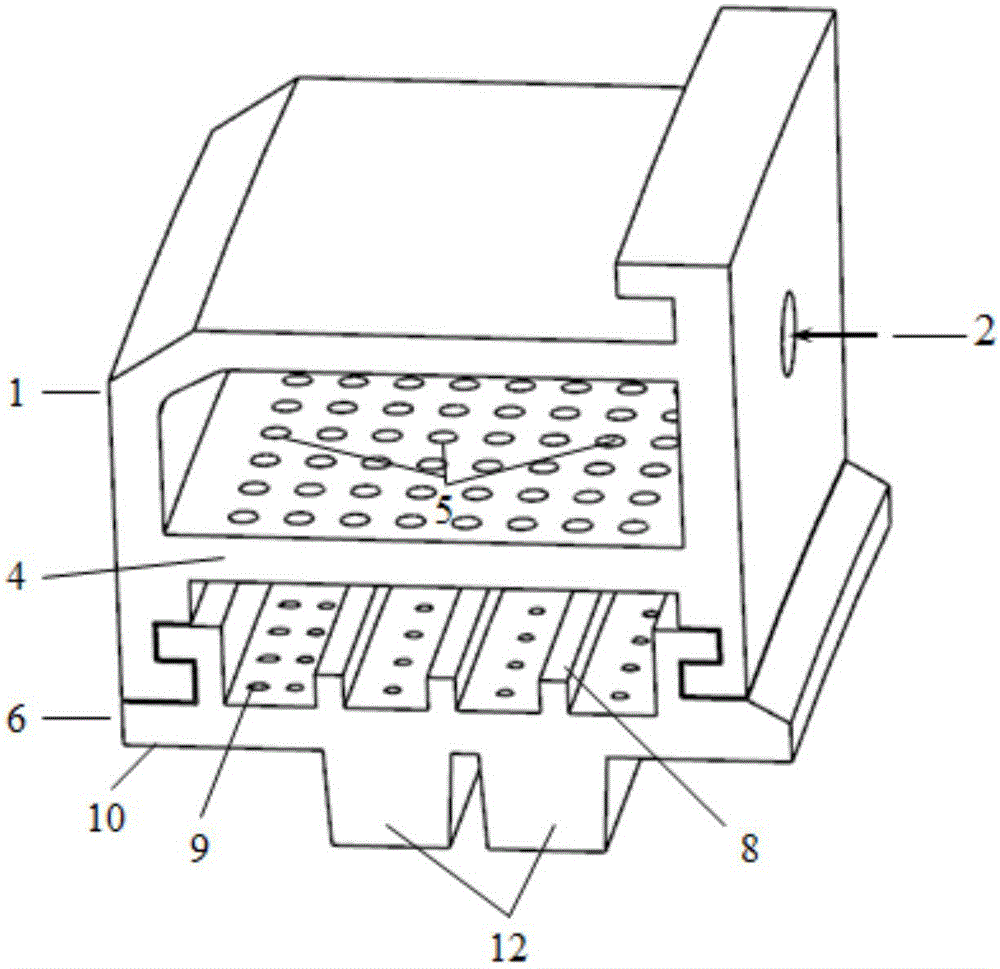

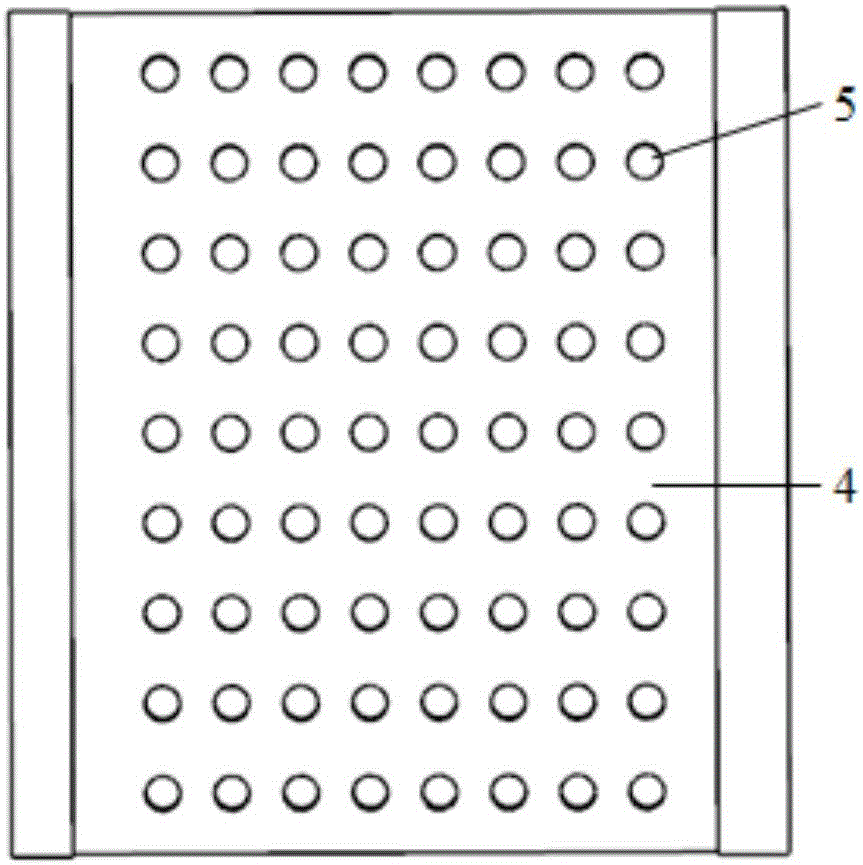

[0022] see Figure 1-Figure 5 , the present invention proposes a novel turbine case structure, and its technical solution is as follows: The present invention discloses a case structure with blade tip clearance control and blade tip flow control, which mainly includes a turbine case, a cooling structure inside the case, and a turbine outer casing. The ring seal structure; the internal cooling structure of the casing defines the cold air intake hole, the impact hole and the impact plate structure, the impact plate and the turbine casing form the first chamber, and a plurality of impact holes are defined on the impact plate; the outer ring of the turbine passes through The coupling mode is connected to the turbine casing structure, which forms a second chamber with the impact plate, and the outer ring defines a plurality of spoiler structures, air film hole structures and anti-leakage structures; the cold air flow enters the first chamber through the air intake hole. The chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com