Load sensing hydraulic system for controlling six-way multiple unit valve

A load sensing and hydraulic system technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., can solve the complex structure of multi-way valves and load sensing pumps, and can not effectively eliminate bypass Throttling loss, lack of pressure adaptation control function and other problems, to achieve the effect of environmental protection, reduce work intensity and reduce power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

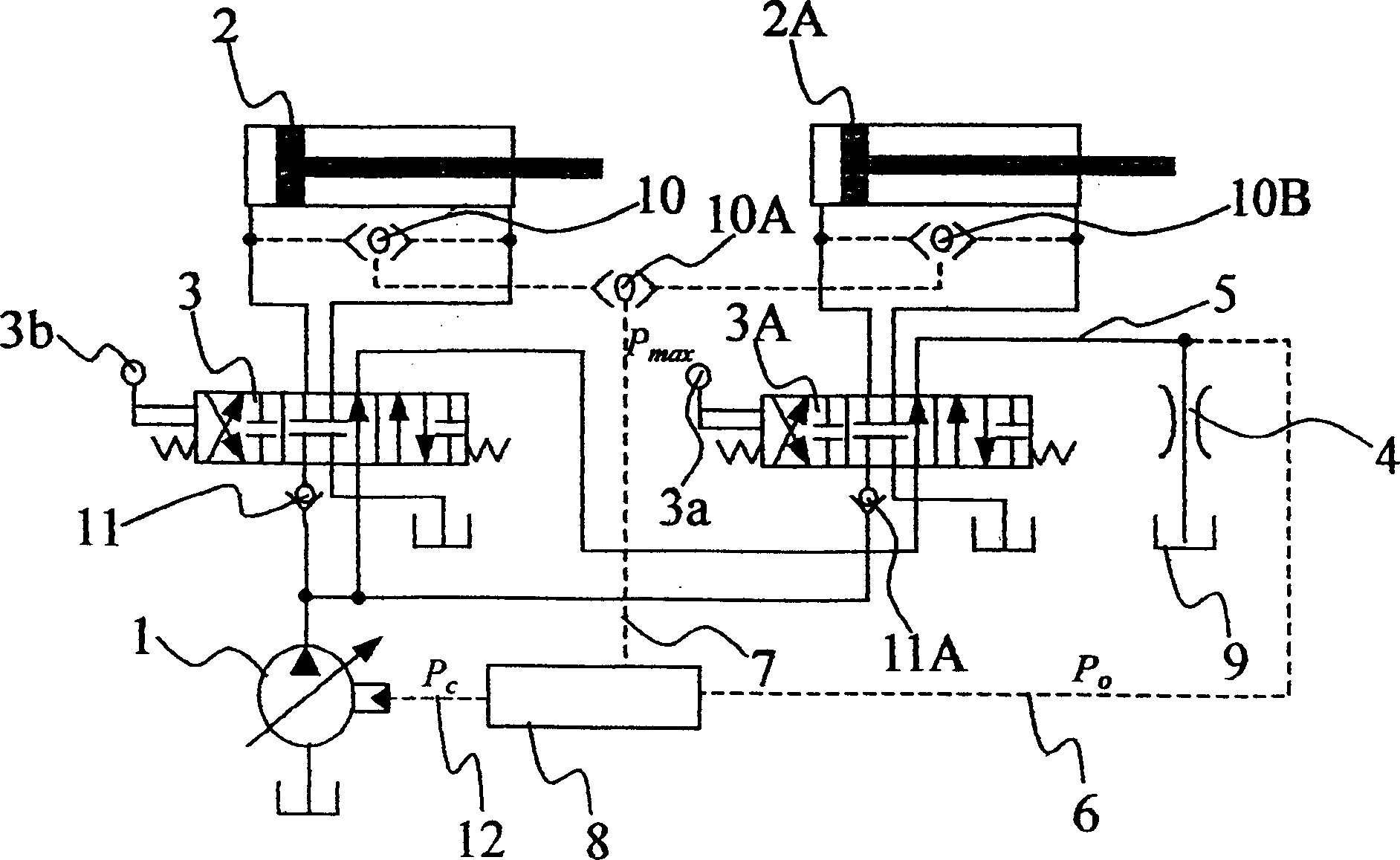

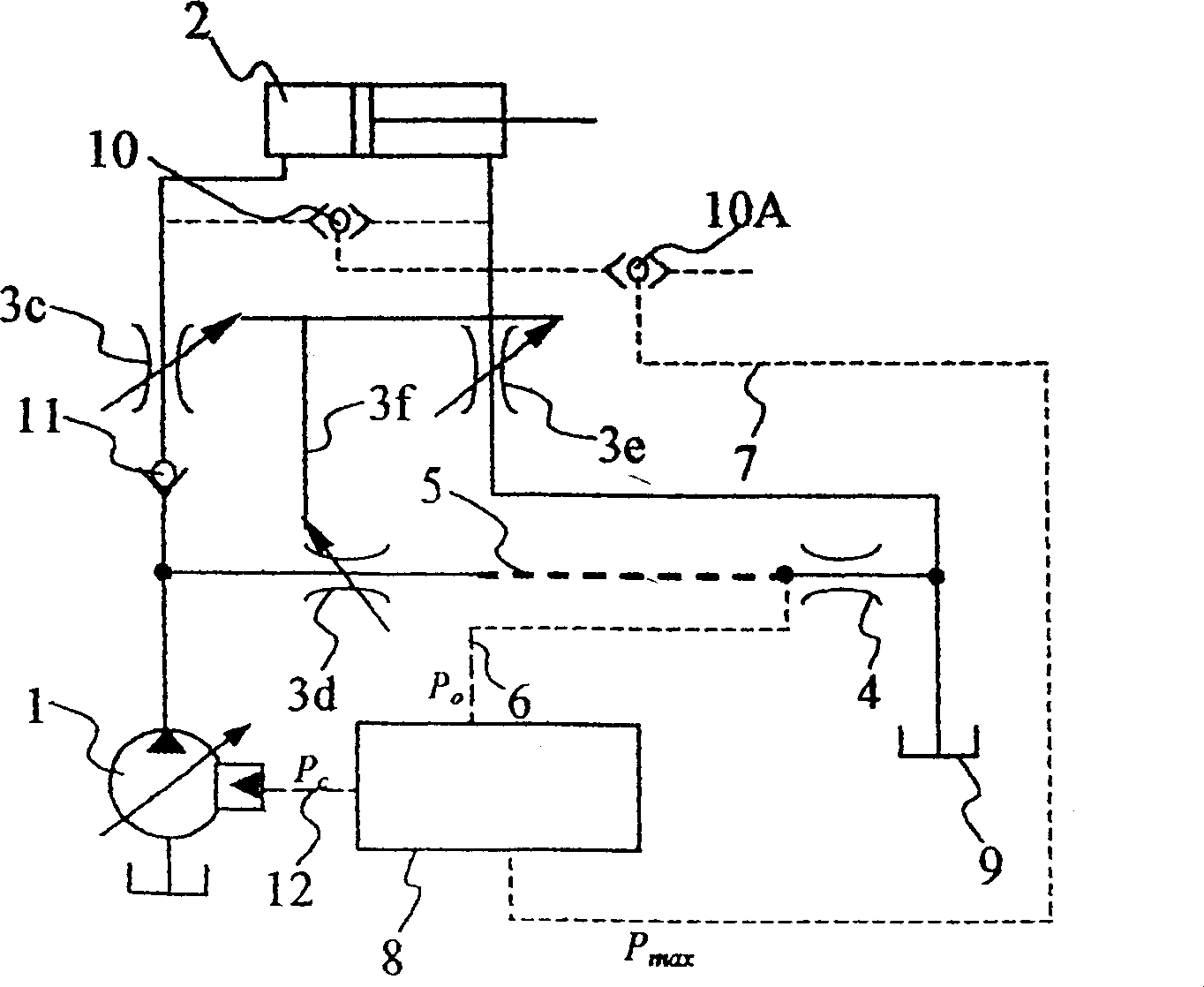

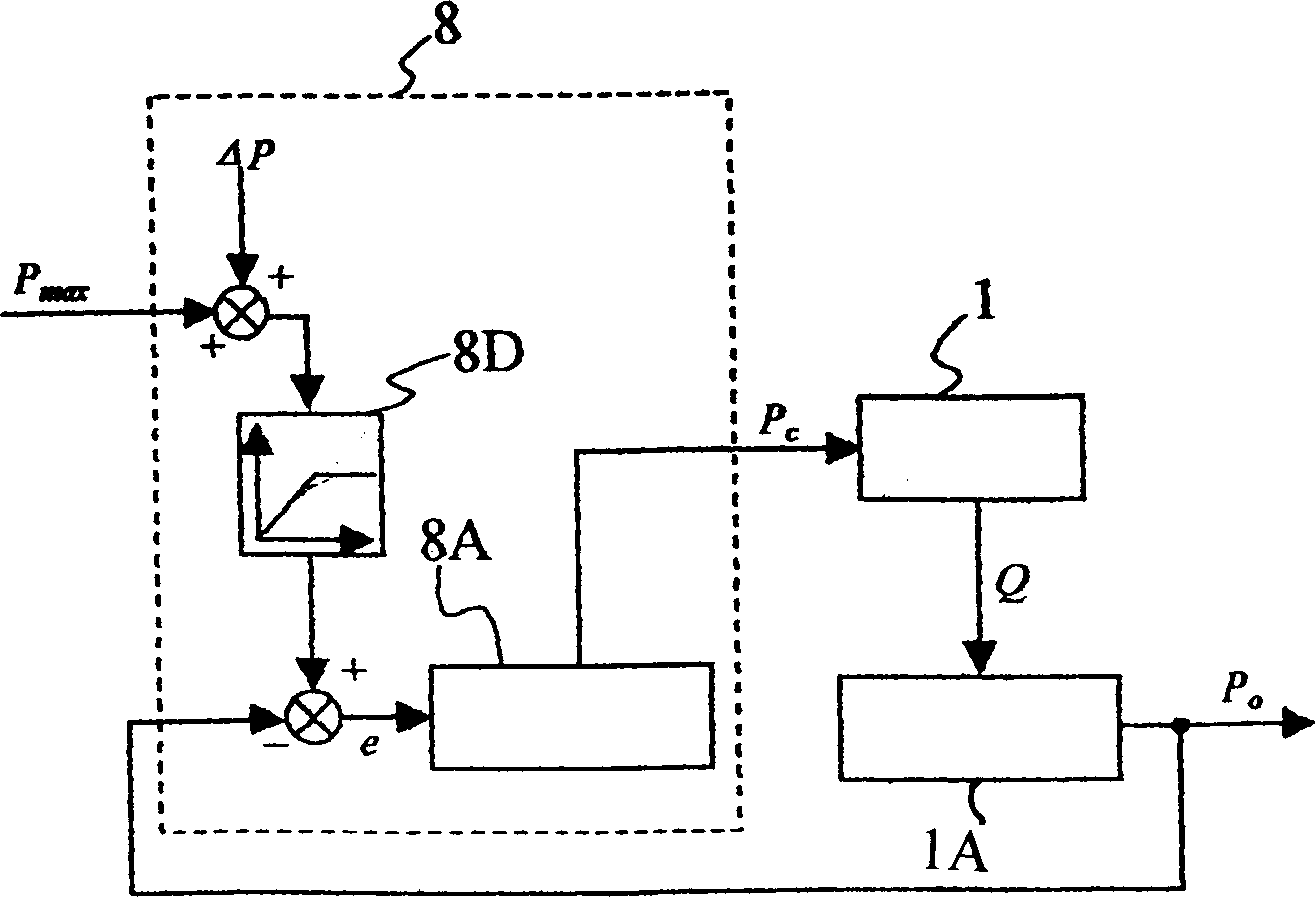

[0027] exist figure 1 Among them, the output port of the hydraulic pump 1 is connected to the input of the load holding check valves 11 and 11A on the one hand, and is also connected to the O port of the first-stage multi-way valve. In this way, the hydraulic oil output by the hydraulic pump is divided into two parts, and one part enters the P port of the multi-way valve through the load holding check valves 11 and 11A. The A port and B port of the multi-way valve are respectively connected with the rodless cavity and the rod cavity of the hydraulic cylinder, and the T port is connected with the oil tank. According to the position of the valve core of the multi-way valve, the pressure oil at the P port is output from the A port or the B port, enters the hydraulic cylinder, and then drives the hydraulic cylinders 2 and 2A; The outlet flows back to the fuel tank. The Q port of the first-stage multi-way valve 3 is connected with the O port of the second-stage multi-way valve 3A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com