Hydraulic control system for novel servo pump control bending machine

A technology of hydraulic control system and servo pump, which is applied to fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc. The effect of reducing resistance loss and pressure leakage loss, reducing resistance loss and leakage loss, and reducing system overflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

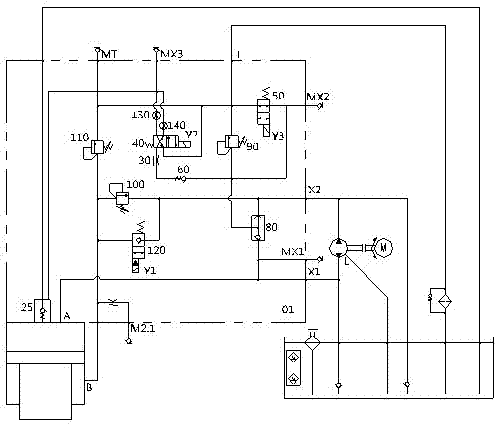

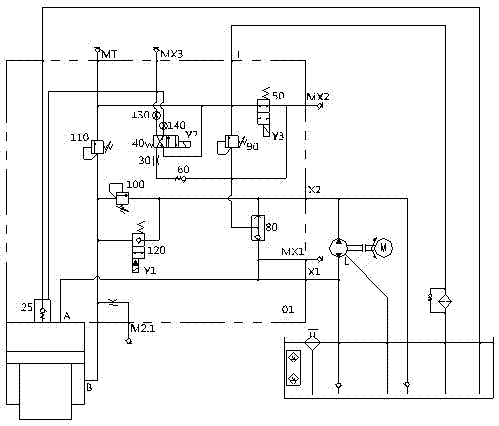

[0013] Embodiment: The connection structure of the control system of this embodiment is as attached figure 1 As shown, it mainly includes the power source and control valve group connected to the numerical control system. Its main feature is that the power source includes a servo motor, a bidirectional quantitative pump connected with the servo motor, and an oil tank; the control valve group includes a pressure valve for adjusting the system pressure. (90), unloading valve (50), also includes shuttle valve (80), check valve (60), reversing valve (40), back pressure valve (100), poppet valve (120), safety valve ( 110) and filling valve (25).

[0014] In this embodiment, the oil inlet and outlet of the two-way quantitative pump are controlled by the shuttle valve (80), the forward oil outlet X1 of the oil pump is directly connected to the upper chamber of the oil cylinder (that is, the rodless chamber A of the oil cylinder), and the reverse oil outlet X2 of the oil pump is The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com