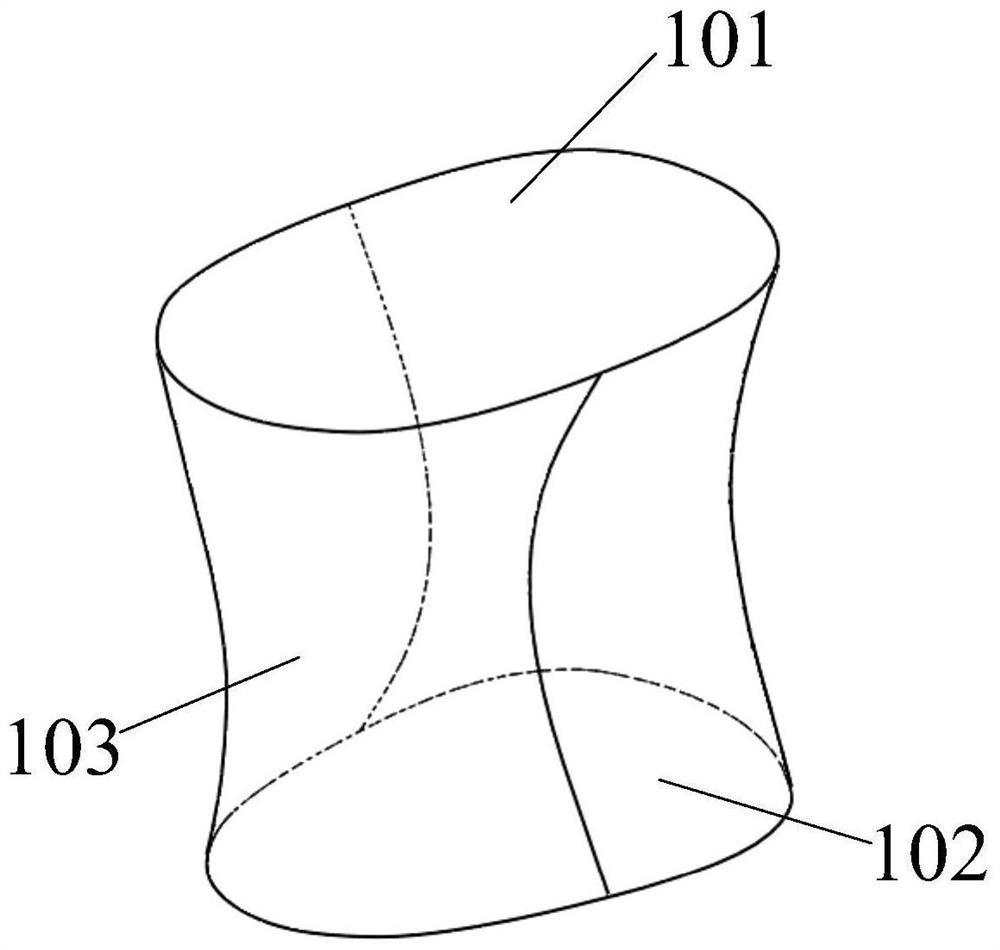

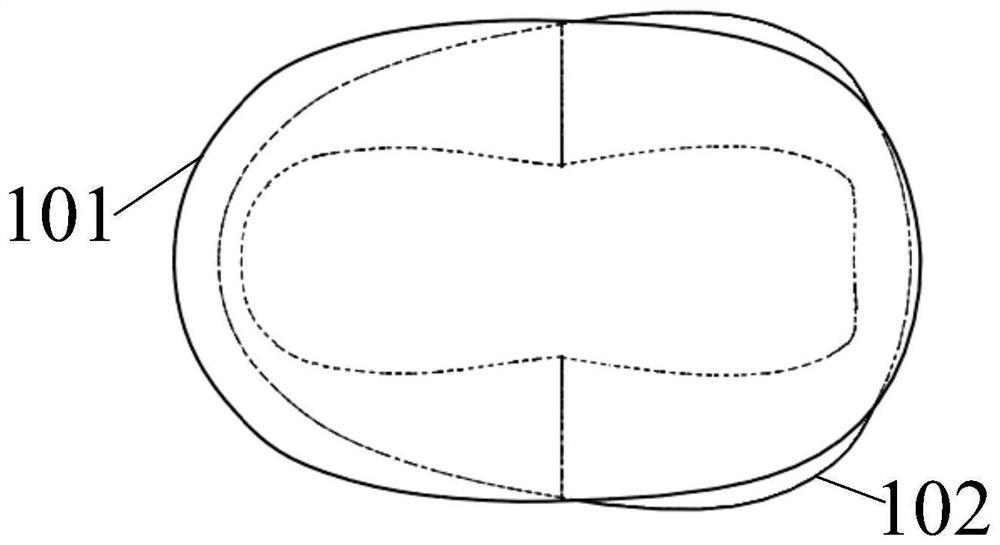

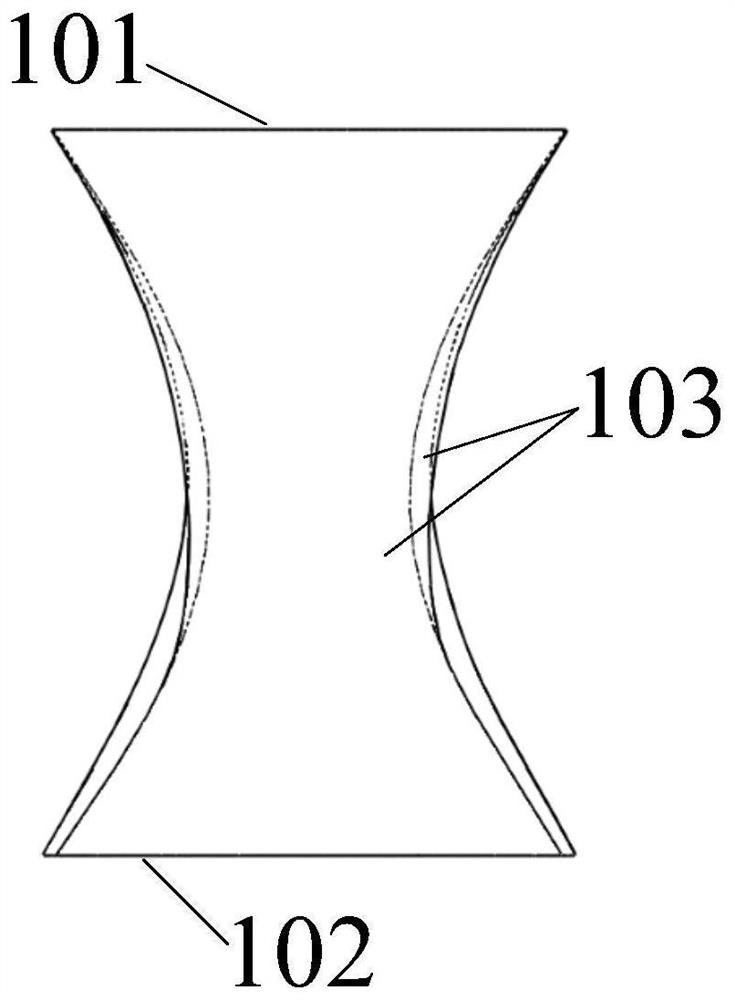

Three-dimensional variable cross-section turbulent flow column structure, heat exchange plate and heat exchanger core

A spoiler column and variable cross-section technology, which is applied in the field of enhanced heat transfer, can solve the problems of reducing drag and the impact of incoming flow, etc., and achieve the effect of increasing the heat transfer coefficient of the wall surface, strengthening the disturbance effect, and being easy to process and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The traditional cylindrical spoiler column, NACA0020 airfoil equal-section spoiler column and the three-dimensional variable cross-section spoiler column structure of the present invention are respectively used in the printed circuit board heat exchanger.

[0044] In the three-dimensional variable cross-section spoiler structure of the present invention, the heights of the low-temperature spoiler 1 and the high-temperature spoiler 2 are both 1mm; All are arc-shaped. The top surface of the low-temperature spoiler column 1 presents a small area, and one end of the bottom surface presents a large area. The areas of the top surface and the bottom surface of the high temperature spoiler column 2 are similar. The specific parameters of the low-temperature spoiler column 1 and the high-temperature spoiler column 2 are shown in Table 1.

[0045] Table 1

[0046]

[0047] A low-temperature spoiler array with 6 rows and 10 columns with a row spacing La of 3.5mm and a column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com