A Shuttle-Type Disc Muffler

A muffler and chip technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of unusable mufflers, poor aerodynamic performance compatibility, and large resistance, and achieve the effect of reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

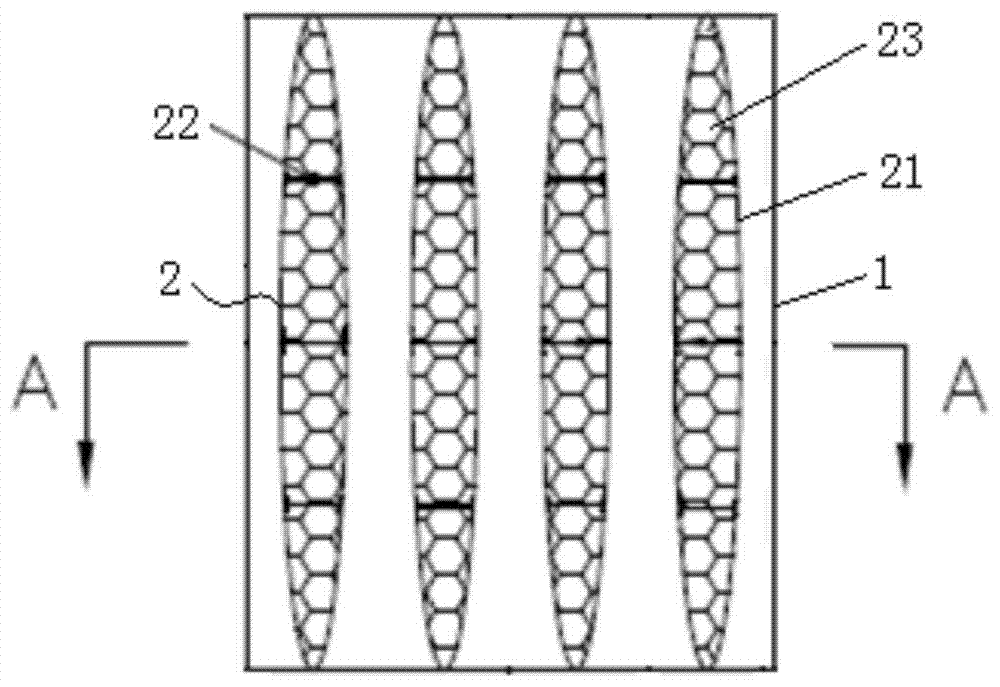

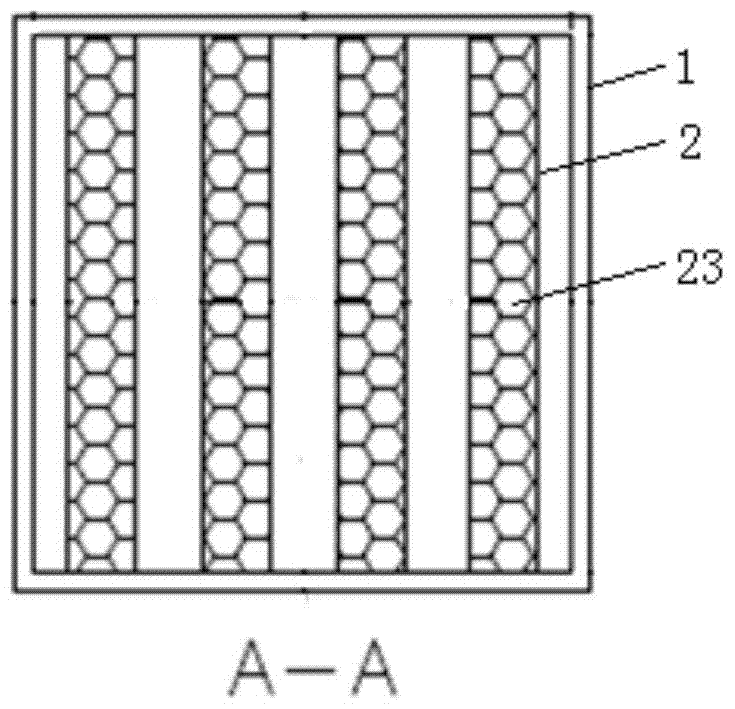

[0015] like figure 1 , figure 2 As shown, the present invention includes a rectangular housing 1, in which several muffler units 2 are equidistantly arranged, and the cross section of each muffler unit 2 along the direction of air flow is shuttle-shaped with two pointed ends and a wide middle.

[0016] In a preferred embodiment, the noise reduction unit 2 includes a perforated protective panel 21 with a shuttle-shaped cross section, and several supports 22 are arranged in the perforated protective panel 21 .

[0017] In a preferred embodiment, the interior of the noise reduction unit 2 can be filled or not filled with resistive sound-absorbing material according to the specific application. Generally, when the perforated protective panel 21 is a microporous plate or an ultra-microporous plate, the interior does not need to be filled with resistive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com